High-temperature liquid drop contact angle testing device and testing method

A technology for testing devices and contact angles, applied in measuring devices, instruments, scientific instruments, etc., which can solve the problem of not being able to truly reflect the wettability of the melt and the substrate, failing to solve the second and third problems, and affecting the accuracy of the contact angle In order to achieve the effect of shortening the experimental period, pure surface and accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The purpose of the present invention is to provide a device and method for accurately measuring the contact angle between metal and metal or metal and ceramics in a high-temperature environment, and two sets of experimental data can be obtained during one experiment. The experimental device of the invention overcomes the disadvantages of the reaction between the melt and the substrate and that only one set of data can be obtained in one experiment in the traditional sessile drop method, and makes efficient and accurate measurement of the contact angle and wetting kinetics possible.

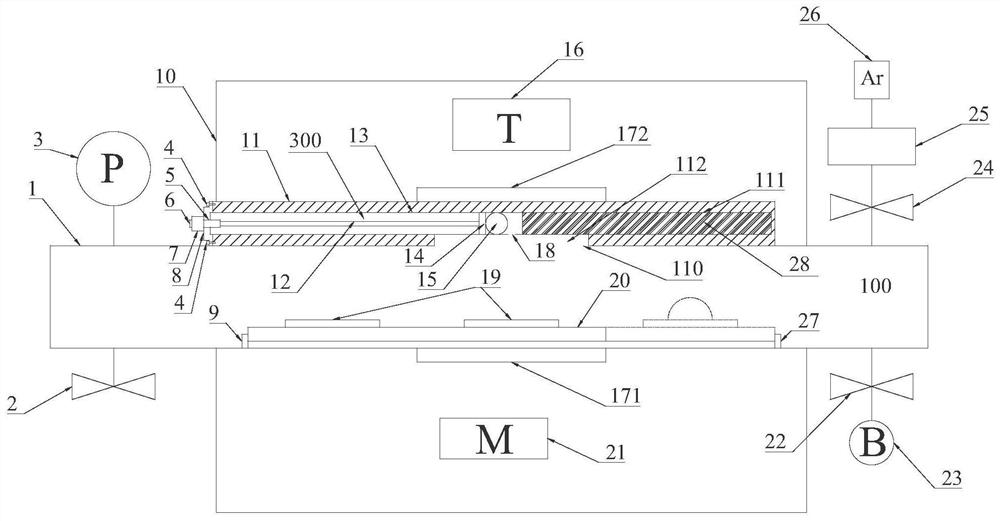

[0036] 1. High temperature contact angle measurement device

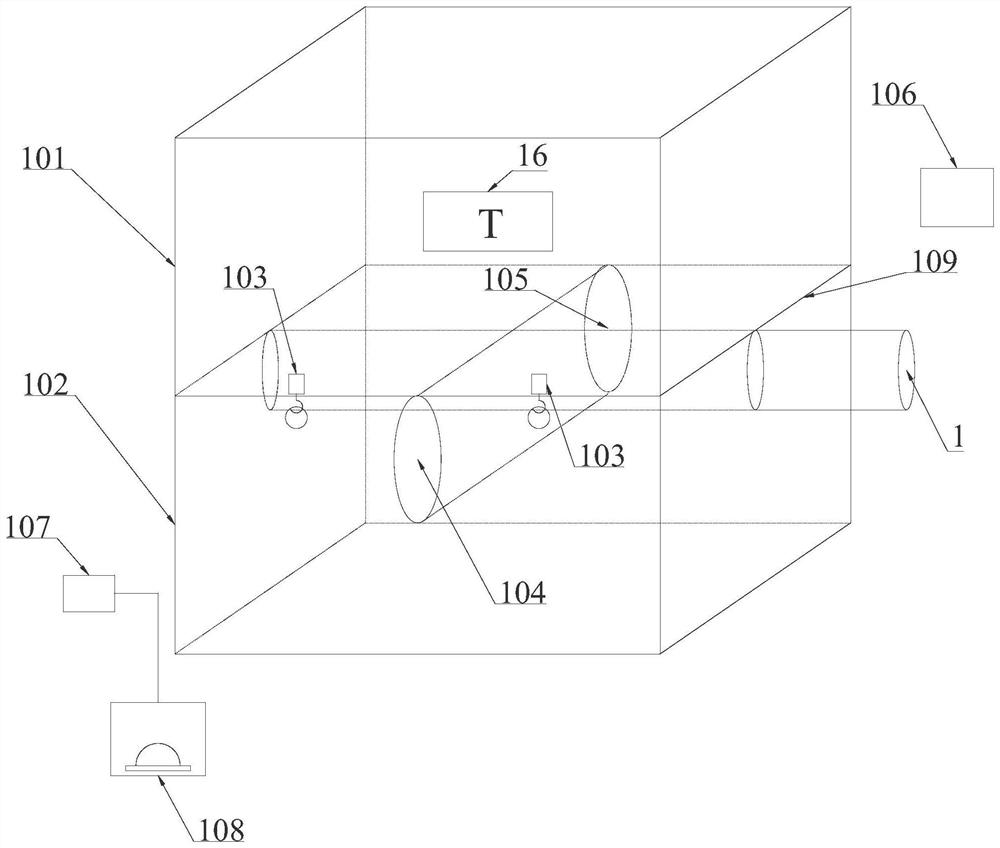

[0037] Such as figure 1 and figure 2 As shown, the high-temperature droplet contact angle testing device of this embodiment includes a box 10 , a reactor 1 , a dropper 13 , a light source 106 , a camera 107 , and a computer 108 electrically connected to the camera 107 .

[0038] The reactor 1 has a first hollow cavity 100 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com