Device for detecting coaxiality of bearing inner ring

A bearing inner ring and detection device technology, which is applied in the field of bearing processing, can solve the problems of lowering the qualified rate of the bearing inner ring, the misalignment between the bearing inner ring and the drive shaft, etc., so as to reduce the probability of scratches, reduce errors, and reduce relative The effect of turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following is attached Figure 1-6 The application is described in further detail.

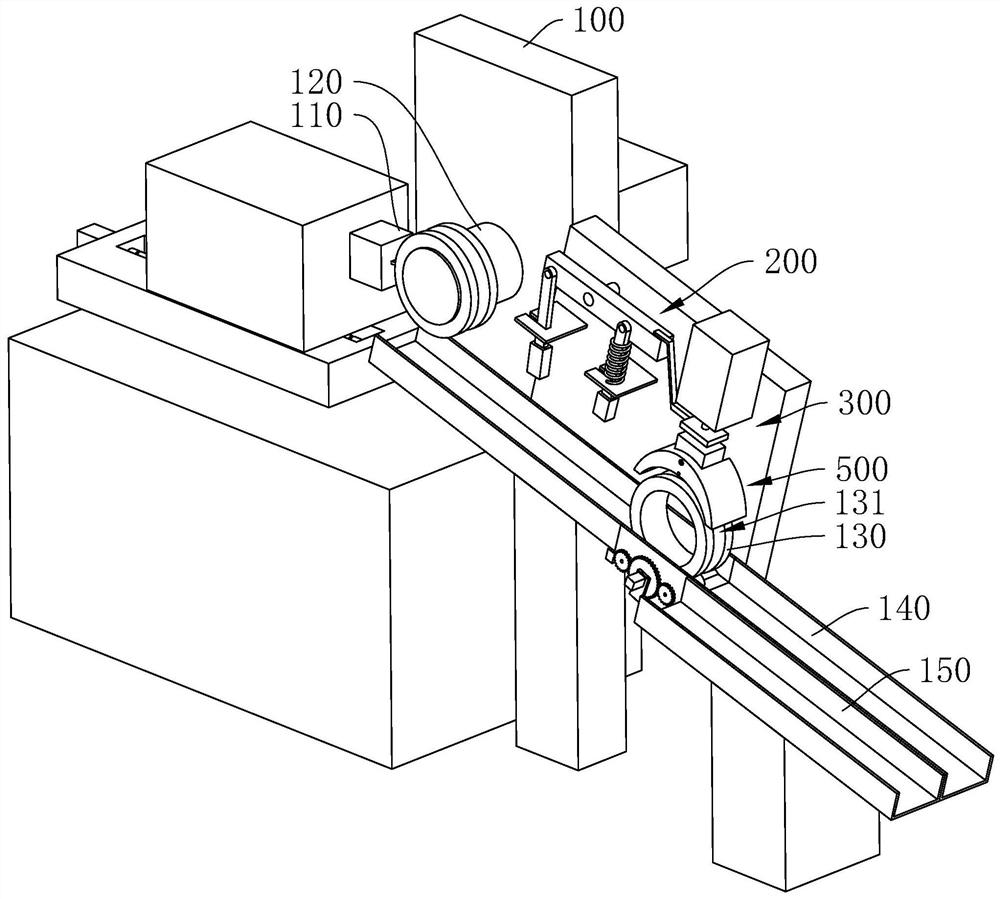

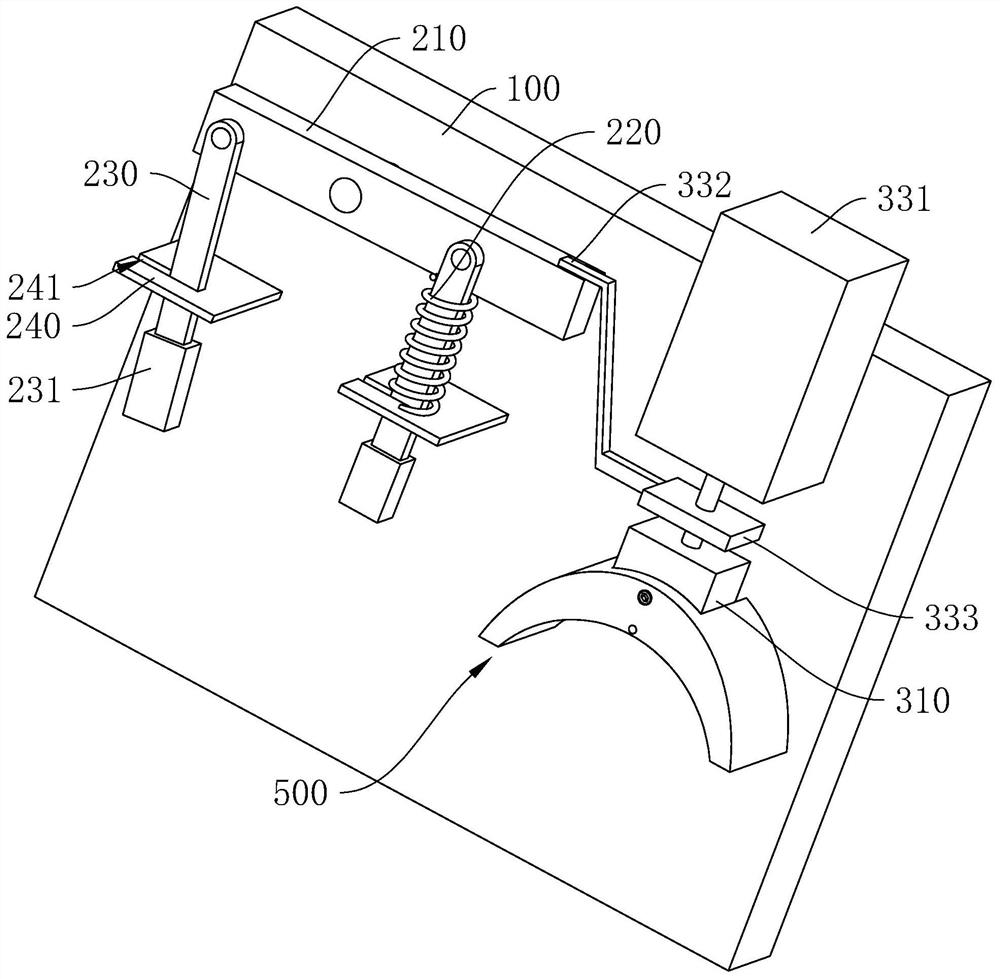

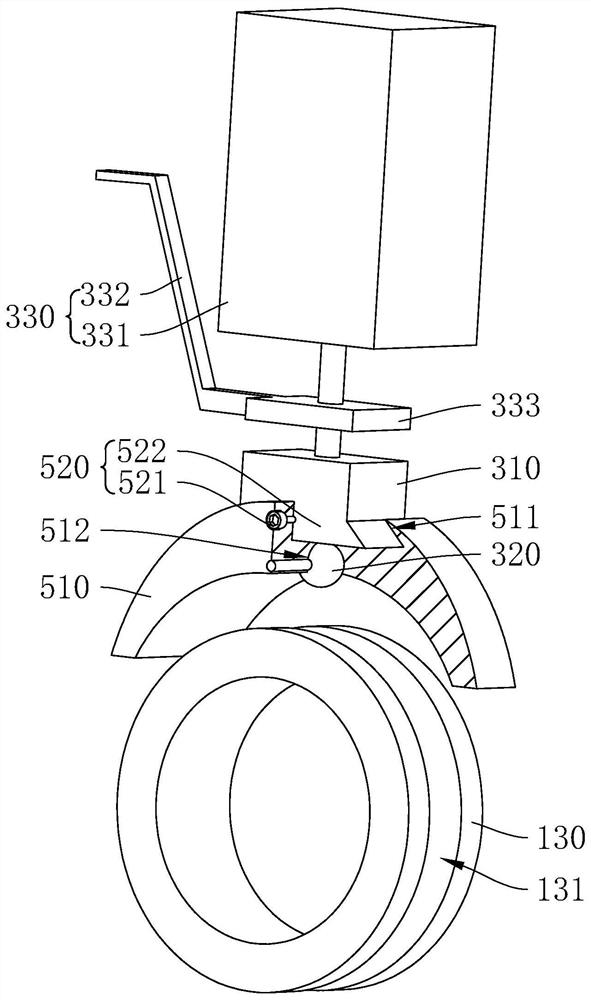

[0039] refer to figure 1 , a detection device for the coaxiality of a bearing inner ring, comprising a frame 100, a turning tool 110 is provided for horizontal sliding on the frame 100, a drive shaft 120 is provided for horizontal rotation on the frame 100, and a bearing inner ring 130 is coaxially installed On the drive shaft 120, the turning tool 110 slides close to the bearing inner ring 130 and turns the outer groove 131 on the outer side wall of the bearing inner ring 130; the inclined discharge slideway 140 is fixedly arranged on the frame 100, and the discharge slideway One end of 140 is inclined upward and is located below the drive shaft 120 , the other end of the discharge slideway 140 is sloped downward, and the bearing inner ring 130 after turning the outer groove 131 falls into the discharge slideway 140 .

[0040] refer to figure 1 and figure 2 , the frame 100 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com