Prefabricated block for switch box and socket box of infilled wall masonry

A prefabricated block and switch box technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of high cost and cost of slotted holes, difficult to control the size and shape of the slotted holes, plastering cracks, etc., so as to reduce the later maintenance cost and appearance. Good look and feel and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The switch box and socket box prefabricated blocks for filling wall masonry of the present invention are determined according to the length, width and height of the switch box and socket box body as a, b, and c respectively Dimensions, including filling wall masonry switch box, socket box prefabricated block body.

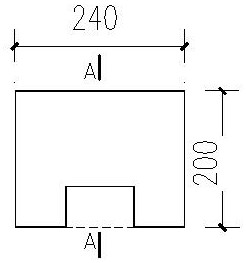

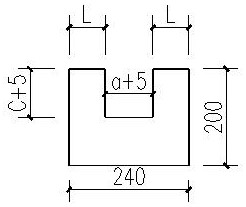

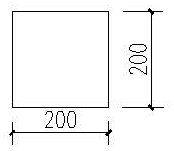

[0026] see now Image 6 , Image 6 It is a three-dimensional schematic diagram of a switch or a socket box according to an embodiment of the present invention, in which a is the length of the switch or the socket box, b is the width of the switch or the socket box, and c is the height of the switch or the socket box. As shown in the figure, the main body of the prefabricated block of the masonry switch box and socket box of the filled wall is a concrete prefabricated block with a length of 240mm, a width of 200mm, and a height of 200mm. There is a groove inside the block to accommodate the switch box and the socket box body, wherein: the length of the groo...

Embodiment 2

[0029] Figure 7 It is a structural schematic diagram of a prefabricated block according to an embodiment of the present invention. The preparation method of the present invention for filling wall masonry switch box, socket box prefabricated block:

[0030] Step 1. Technical preparation: sort out the switch boxes and socket box slots in the masonry infill wall on the drawings, make statistics, and preliminarily estimate the quantity; determine the specific size of the switch box and socket box according to the electrical construction drawing.

[0031] Step 2. Mold making, use 1mm thick steel plate to cut into small pieces of steel plate of different shapes and sizes according to the size, and accurately weld and process it into a mold with grooves according to the design size of the mold; after the welding is completed, the welding edge of the mold is polished to ensure the processing The welding part is smooth and straight, and the final processing is completed to shape the ...

Embodiment 3

[0036] Figure 8 It is a schematic diagram of the use state of the prefabricated block in the embodiment of the present invention. The use method of the present invention for filling wall masonry switch boxes and socket box prefabricated blocks:

[0037] Step 1. Combined with the masonry brick arrangement diagram and disclosure content, move the prefabricated blocks to the corresponding location according to the specific needs of the floor.

[0038] Step 2. When building to the elevation of the switch box and socket box, according to the position of the exposed wire tube reserved in the structure, lay the prefabricated block at the corresponding position to ensure that the groove of the prefabricated block is on the same line as the reserved wire tube It is convenient for the wire pipe to be connected to the installed switch box and socket box in the later stage.

[0039] Step 3. When the wall is a switch box, the groove of the block faces upward; if it is a socket box, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com