Microwave dielectric ceramic material and preparation method thereof

A technology of microwave dielectric ceramics and matrix materials, applied in the field of microwave dielectric ceramics, can solve the problems of high sintering temperature, hindering the practical application of ceramics, and poor thermal shock resistance of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

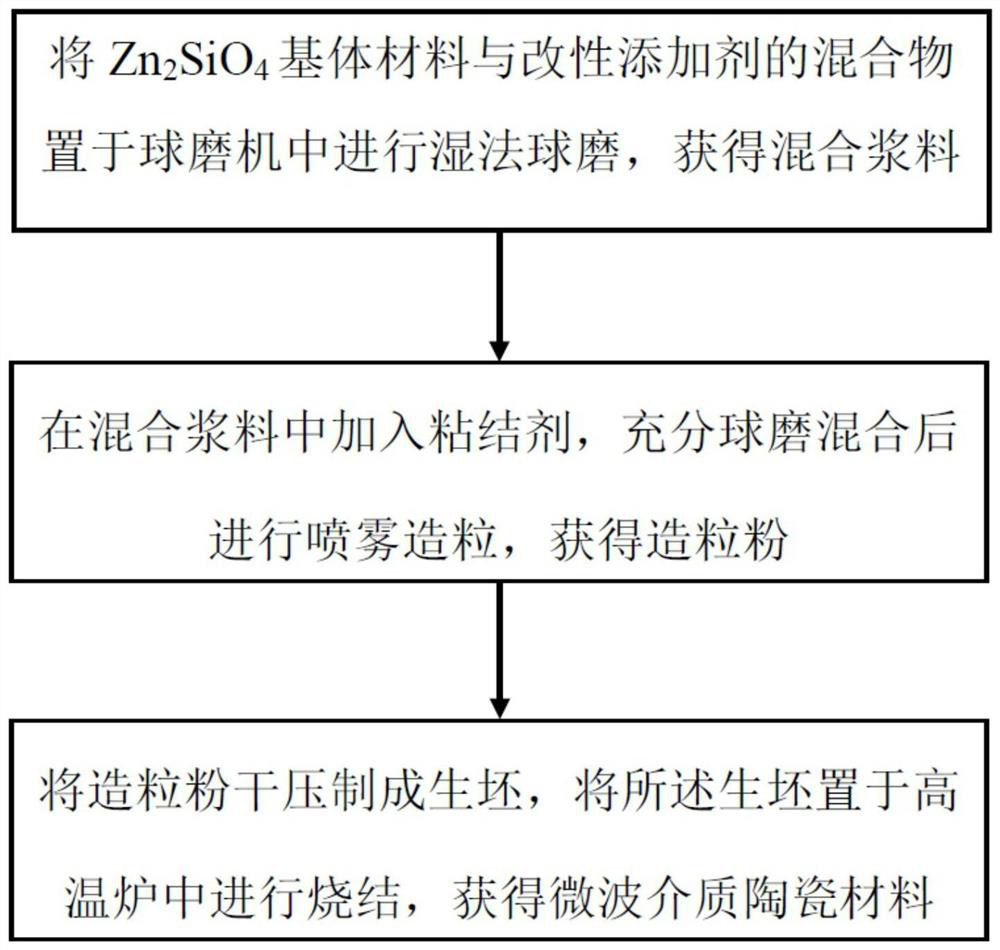

[0038] The embodiment of the present invention also provides the preparation method of the above-mentioned microwave dielectric ceramic material, refer to figure 1 , the preparation method comprises:

[0039] S10, mixing: the Zn 2 SiO 4 The mixture of the base material and the modifying additive is placed in a ball mill for wet ball milling to obtain a mixed slurry.

[0040] Wherein, based on the total mass of the microwave dielectric ceramic material, the mass percentage of the base material is 82%-90%, and the mass percentage of the modifying additive is 10%-18%.

[0041] Preferably, the Zn 2 SiO 4 The preparation of the base material includes:

[0042] Ingredients: the raw materials ZnO and SiO 2 The mixture prepared according to the stoichiometric ratio (2:1) is placed in a ball mill for wet ball milling to obtain the first slurry;

[0043] Pre-burning: the first slurry is dried and sieved, then placed in a high-temperature furnace for pre-burning, and the Zn 2 SiO...

Embodiment 1

[0053] Example 1: Zn 2 SiO 4 Preparation of matrix material

[0054] The raw materials ZnO and SiO 2 According to Zn 2 SiO 4 The stoichiometric ratio (2:1) was prepared to obtain a mixture, and the mixture was wet ball milled for 10 hours, dried, and sieved to obtain a mixed powder; wherein, the mass ratio of raw material mixture, ball milling beads, and deionized water was 1:3: 5. The mass ratio of ball milling beads with diameters of 3mm, 5mm and 8mm is 1:1:1;

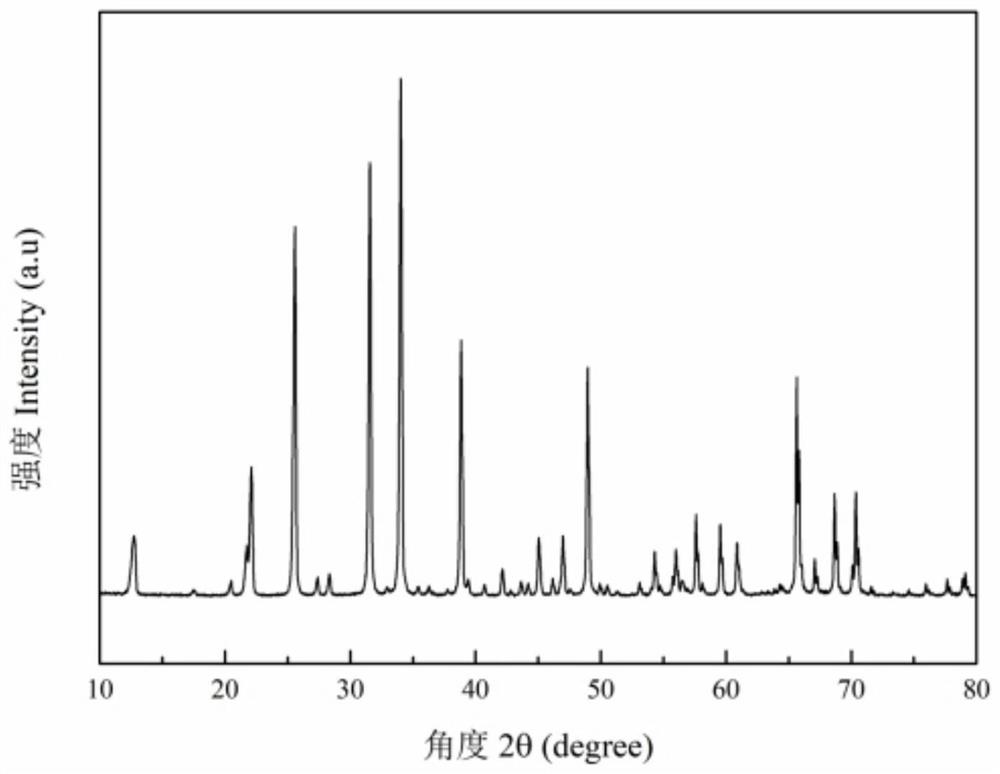

[0055] Put the mixed powder into a high-temperature box furnace and pre-fire at 1100°C for 3 hours, then ball mill the pre-fired powder for 10 hours, dry and sieve to obtain the main powder Zn 2 SiO 4 . figure 2 is the Zn of the microwave dielectric ceramic material provided in the above embodiment 1 2 SiO 4 The X-ray diffraction pattern of the base material, from figure 2 It can be known that the raw materials ZnO and SiO 2 Zn was successfully prepared 2 SiO 4 The main powder of the phase.

Embodiment 2~6

[0057] In embodiment 2~6, the Zn of each embodiment 2 SiO 4 The mass percentages of matrix material and various modification additives are shown in Table 1, wherein, the Zn 2 SiO 4 The base material is the base material prepared in Example 1.

[0058] Table 1: Zn 2 SiO 4 Mass percentage of matrix material and various modifying additives

[0059] Composition (wt%) Zn 2 SiO 4

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com