Calendering device of extrusion casting machine

A technology of extrusion casting and calendering device, applied in coating and other directions, can solve the problem that the calendering device cannot meet the needs of high-speed production, cannot take away the surface heat of the pressure roller, and reduce the production and processing efficiency of film materials, etc. Simple and quick installation, avoids film quality degradation, and shortens the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. DETAILED DESCRIPTION OF THE INVENTION The present invention is not intended to limit the invention. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

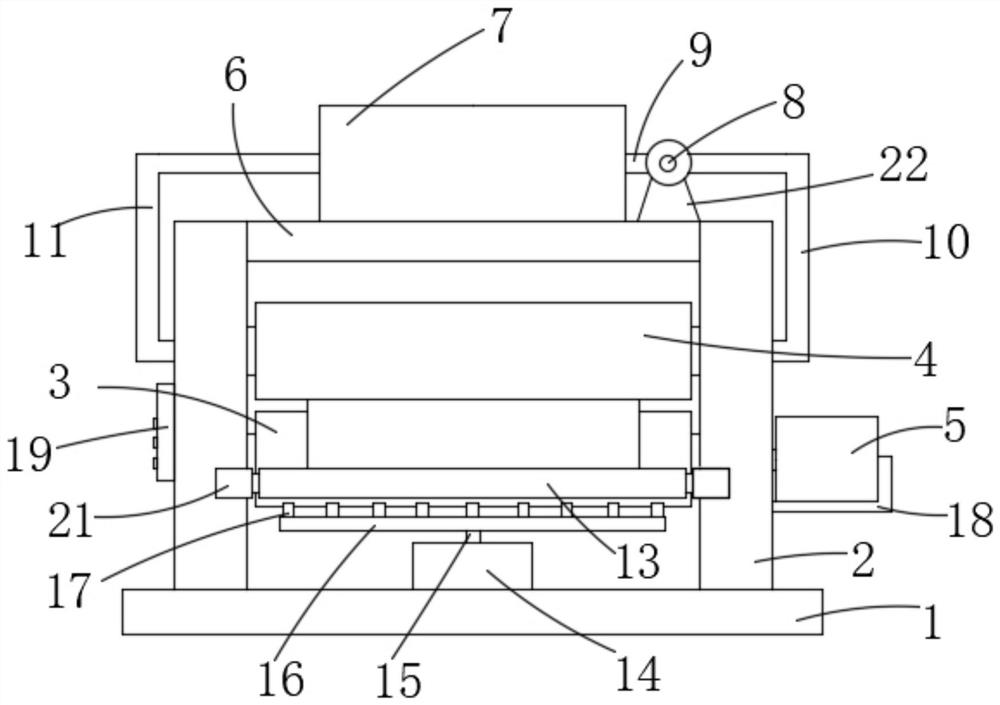

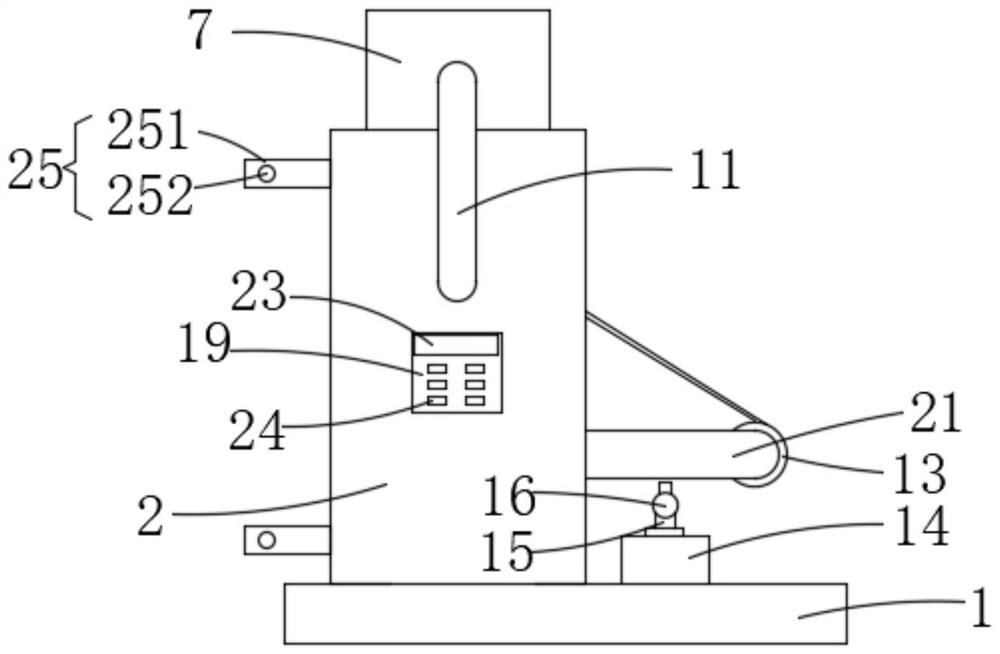

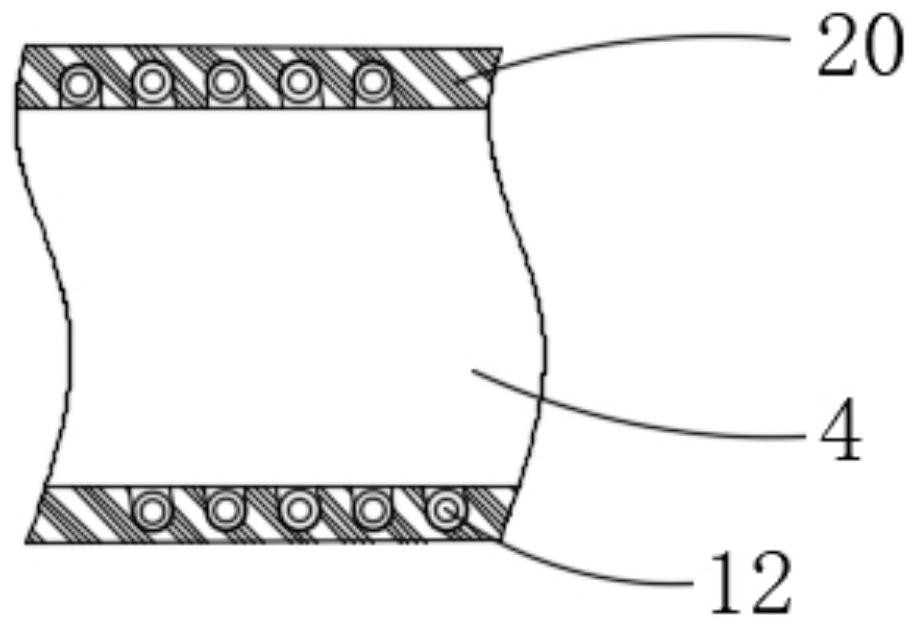

[0025] The present invention provides Figure 1-5 The extension device of the extruded casting machine includes a base 1, two sides of the base 1, two sets of column 2, and the inner wall of the column 2 sequentially rotate on the inner wall of the column 2, and the active roller 3 and the driven roller 4, the column 2 On the outer wall, the drive motor 5 is mounted. The output shaft of the drive motor 5 is fixed to the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com