Negative pressure adsorption type hardware surface polishing machining equipment

A technology for surface polishing and processing equipment, applied in metal processing equipment, surface polishing machine tools, grinding/polishing equipment, etc., can solve the problems of slow burr discharge speed and burr adsorption force, and reduce the bearing capacity. , the effect of speeding up the discharge speed and speeding up the swing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] as attached figure 1 to attach Figure 5 Shown:

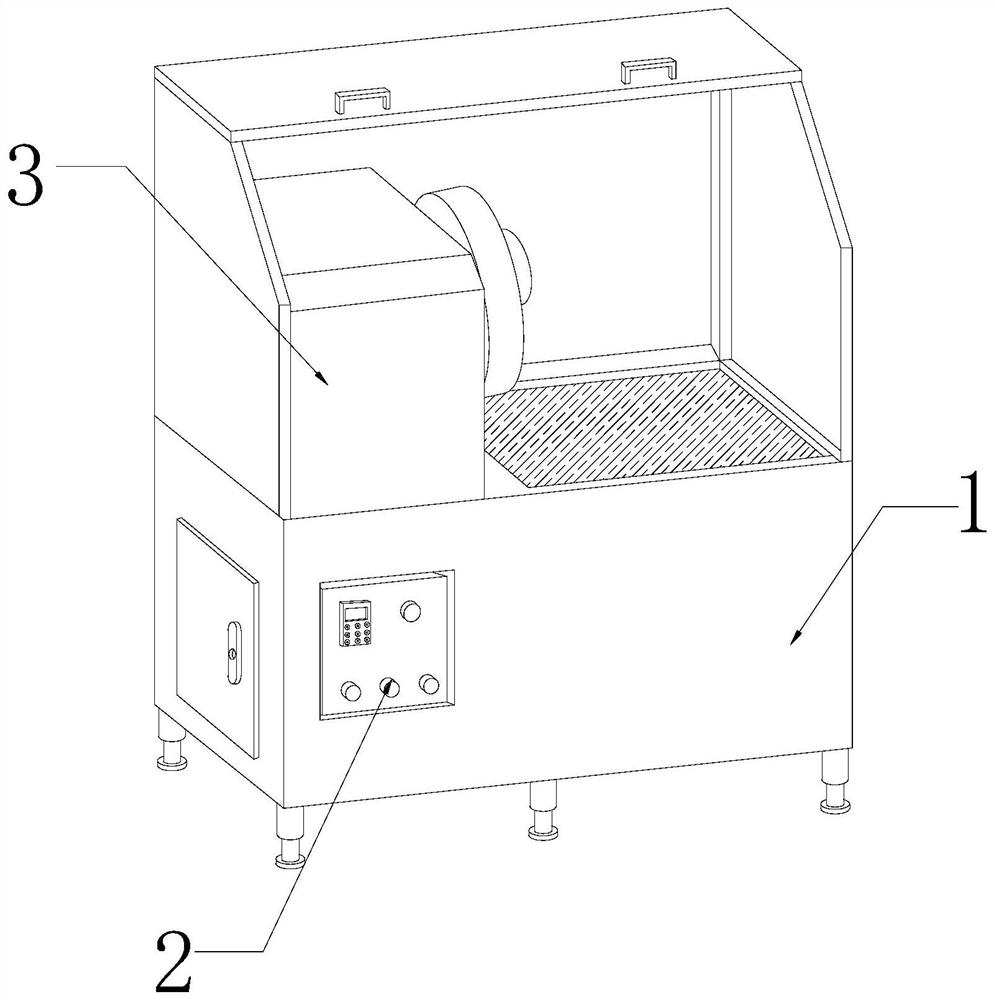

[0026] The invention provides a negative pressure adsorption surface polishing processing equipment for hardware products, the structure of which includes a polishing table 1, a control panel 2, and a polisher 3, the control panel 2 is arranged on the front of the polishing table On the left top of polishing table 1.

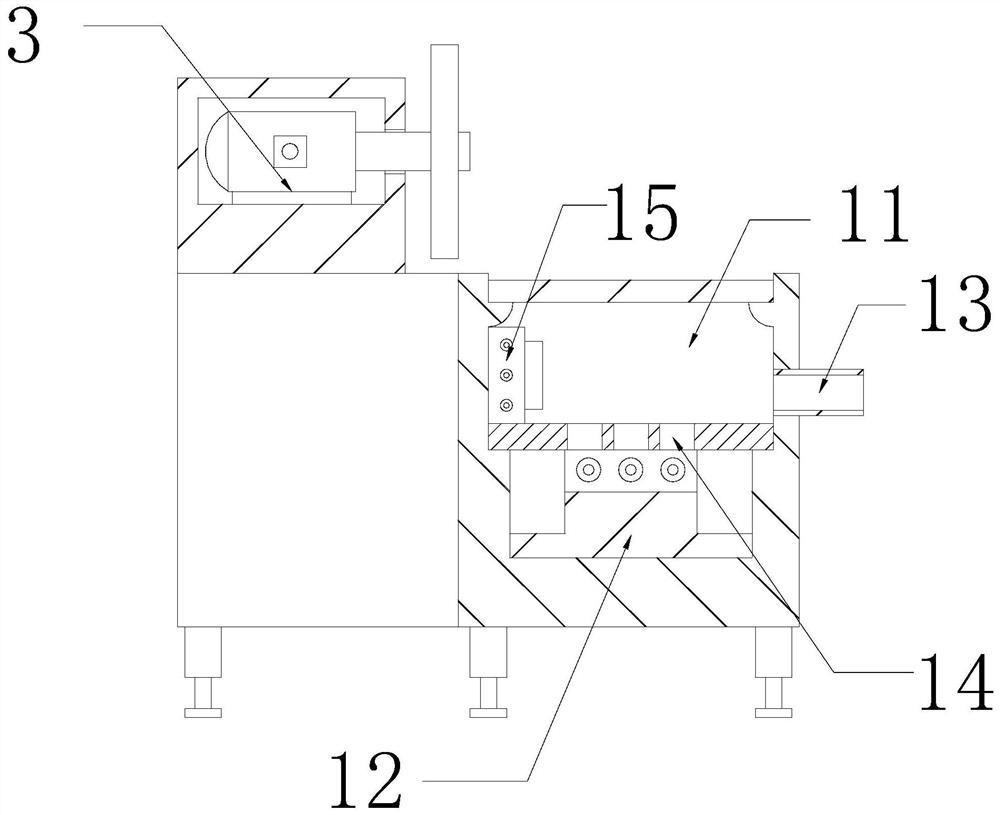

[0027] The polishing table 1 is provided with a stacking chamber 11, a negative pressure machine 12, a chip removal pipe 13, an air flow port 14, and a fan 15. Below the accumulation chamber 11, the chip removal pipe 13 runs through the inner and outer walls of the right side of the accumulation chamber 11 horizontally, the air flow port 14 is arranged on the top of the negative pressure machine 12, and the fan 15 is fixed on the left inner wall of the accumulation chamber 11.

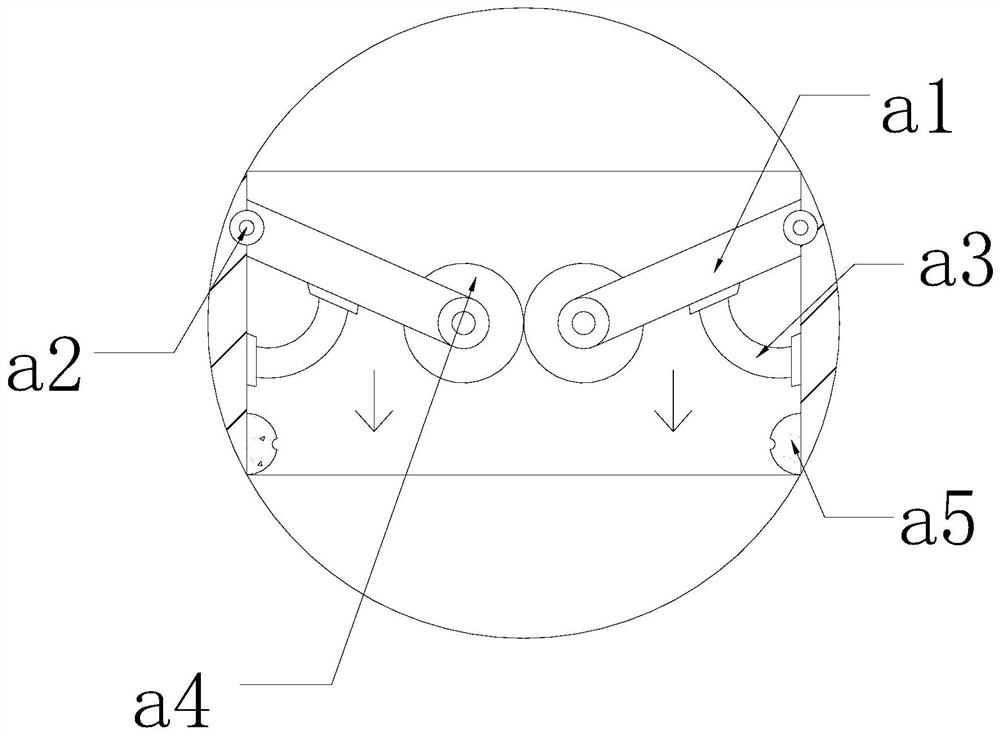

[0028] Wherein, the airflow port 14 is provided with a support rod a1, an engaging shaft a2, a reset bar a3, a clamping block ...

Embodiment 2

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035]Wherein, the support rod a1 is provided with a card slot r1, a moving plate r2, and a telescopic rod r3, the card slot r1 is recessed on the upper surface of the support rod a1, the moving plate r2 is set inside the card slot r1, and the telescopic rod r3 is installed between the bottom surface of the moving plate r2 and the inner bottom of the card slot r1, and the moving plate r2 respectively cooperates with two identical telescopic rods r3, which can increase the driving force of the telescopic rod r3 on the moving plate r2 and speed up the moving plate The speed at which r2 moves upwards speeds up the moving plate r2 to push up the burrs on the top of the support rod a1, reducing the accumulation of burrs on the top of the support rod a1.

[0036] Wherein, the moving plate r2 is provided with an inner groove t1, a bouncing ball t2, a bouncing block t3, and a pushing block t4, the inner groove t1 is set insid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com