Grinding equipment and grinding method for end face gears for turrets

A technology of face teeth and turret, which is applied in the field of face gear grinding equipment for turrets, can solve the problem that the grinding equipment does not have good precision grinding equipment, etc., and achieve the effect of good alignment accuracy of the face teeth and good grinding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

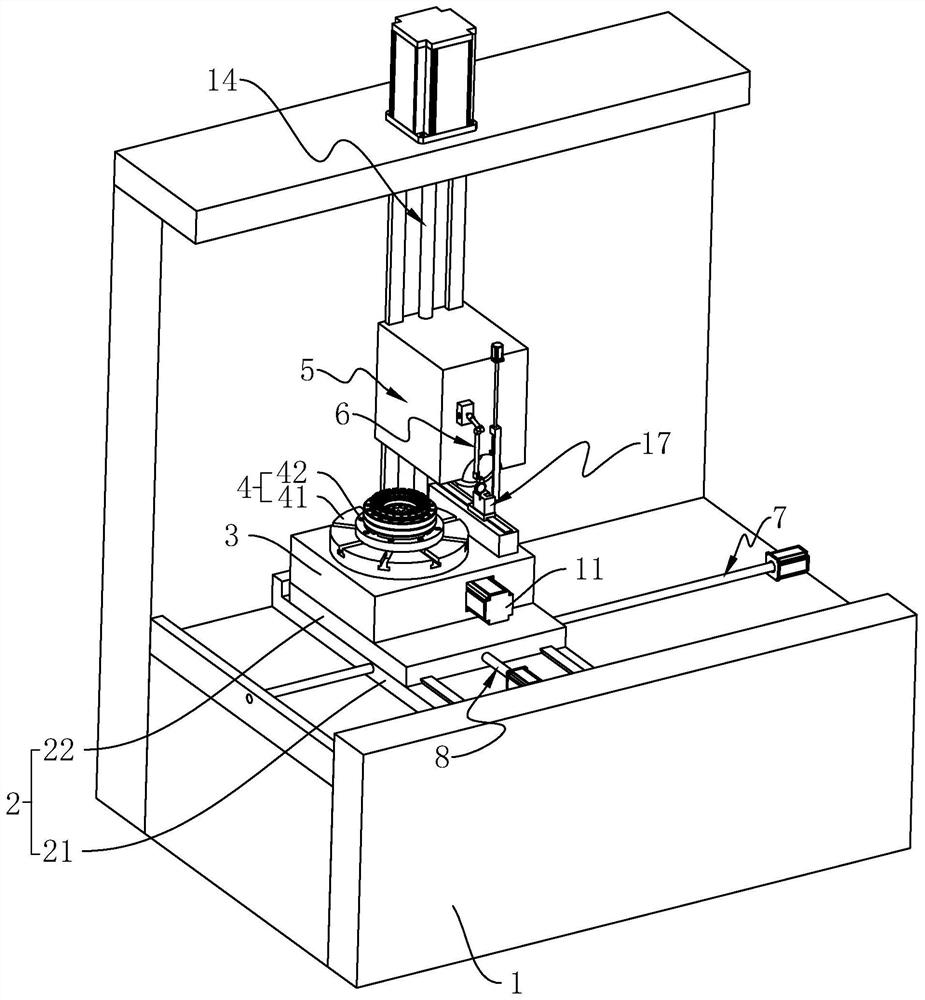

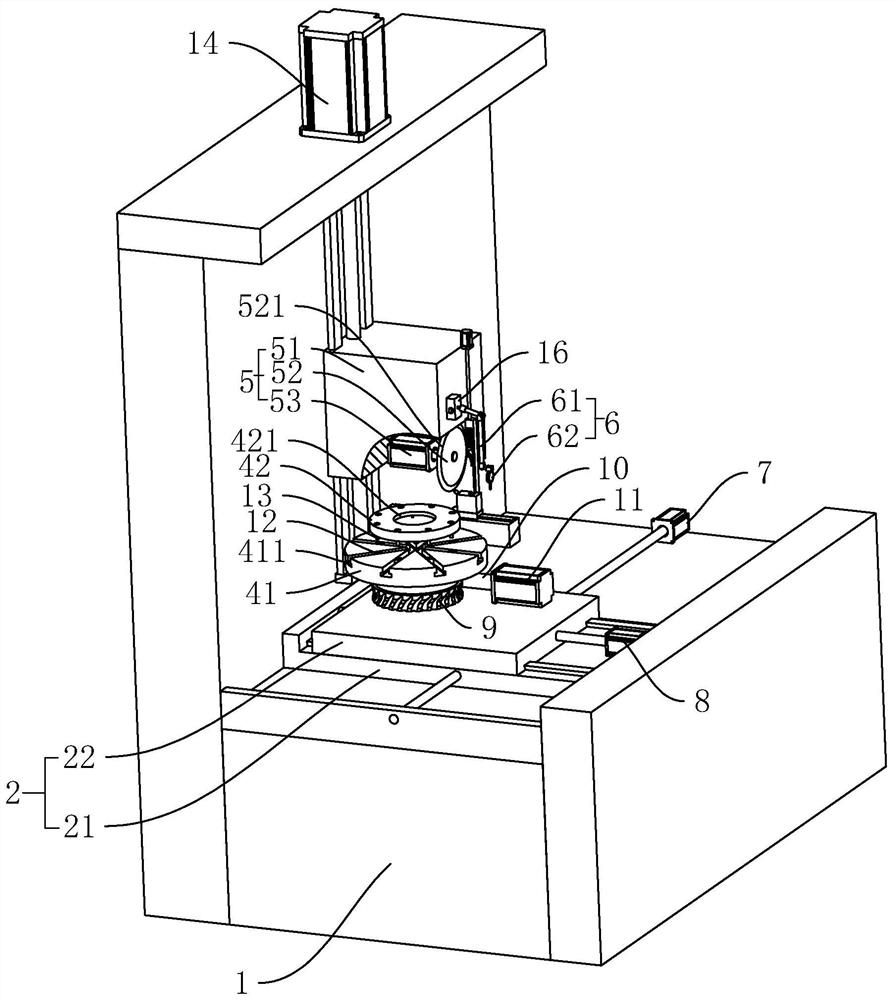

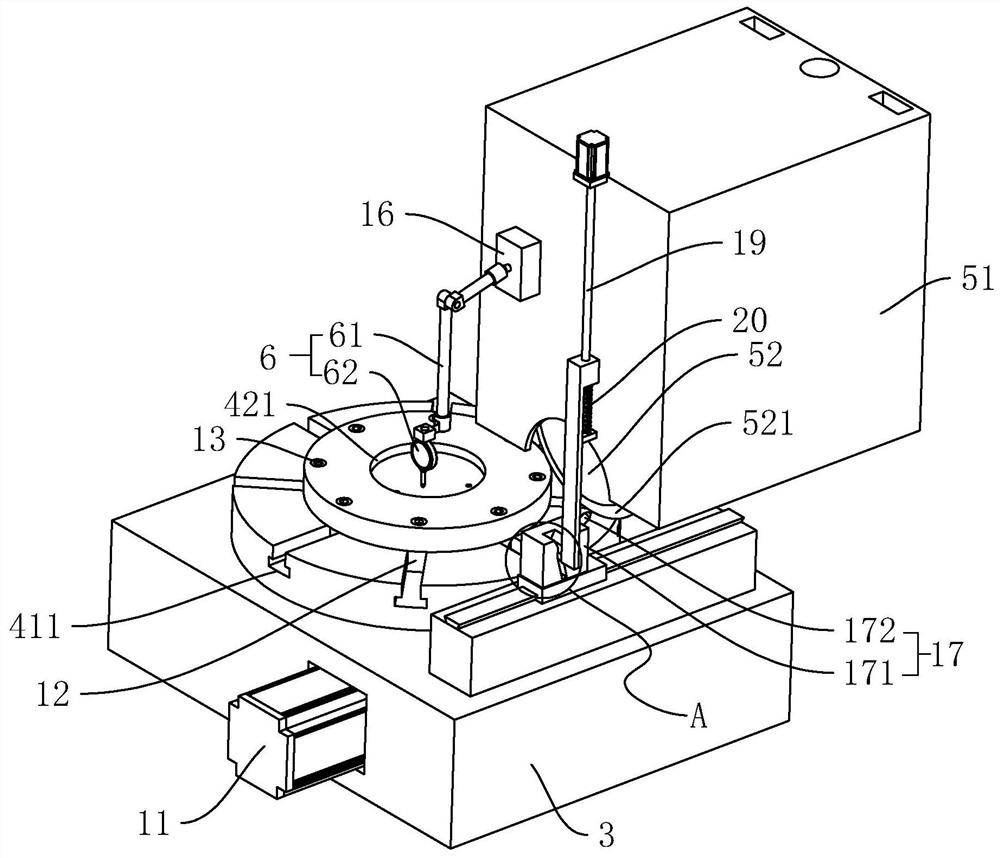

[0044] The following is attached Figure 1-5 The application is described in further detail.

[0045] The embodiment of the present application discloses a kind of grinding equipment for the face teeth of the turret, such as figure 1 As shown, it includes a frame 1 , and also includes an XY-axis moving platform 2 , a workbench 3 , a mounting seat 4 , a grinding device 5 and a detection device 6 .

[0046] Such as figure 1 As shown, the XY-axis mobile platform 2 is arranged on the frame 1, and the XY-axis mobile platform 2 includes an X-axis mobile platform 21 and a Y-axis mobile platform 22, wherein the X-axis mobile platform 21 is slidably connected to the frame 1 along the X-axis direction, The Y-axis mobile platform 22 is positioned at the upper end surface of the X-axis mobile platform 21, and the frame 1 is provided with a driving part-7, and the driving part-7 includes a screw mandrel that is rotatably connected to the frame 1 and is threadedly connected with the X-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com