Basic heterogeneous catalyst for nitroformylation reaction and preparation and application

A heterogeneous catalyst, nitrogen formyl technology, applied in the preparation of organic compounds, catalysts for physical/chemical processes, preparation of carboxylic acid amides, etc., can solve the problems of harsh reaction conditions, low reaction activity, and difficulty in separating catalysts from reaction materials. , to achieve the effect of simple preparation method, high stability and excellent catalytic reaction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

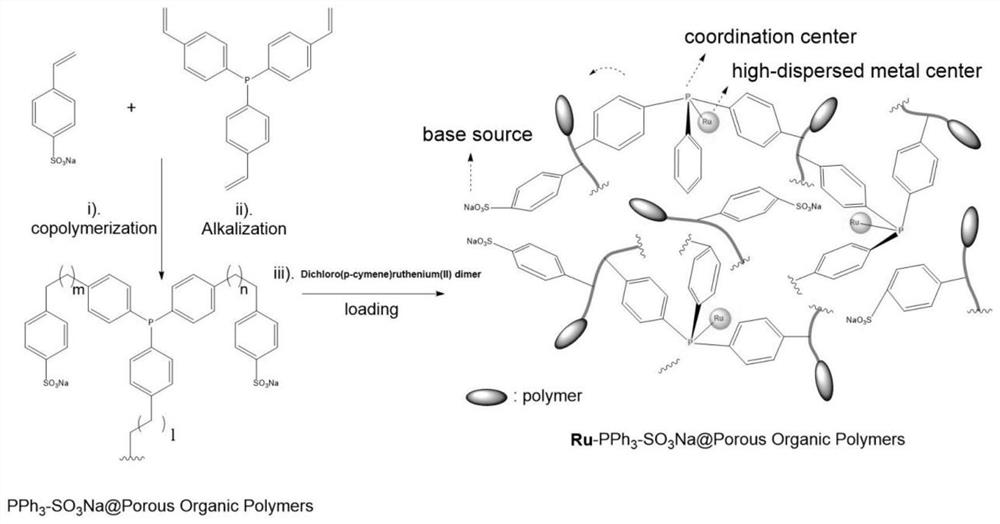

[0027] Under 298K and argon protection atmosphere, 3.0 grams of tris (4-vinylphenyl) phosphine and 0.95 grams of sodium styrene sulfonate were dissolved in 50.0 ml of tetrahydrofuran solvent, and 0.075 grams of free radical initiator was added to the above solution. Azodiisobutyronitrile, stirred for 3 hours. The stirred solution was transferred to a hydrothermal autoclave, and polymerized by solvothermal method at 373K and an inert gas atmosphere for 24 hours. Cool to room temperature after the above-mentioned polymerization, and vacuum remove the solvent at 333K to obtain a porous organic copolymer containing triphenylphosphine and sodium sulfonate.

[0028] Under 298K and an inert gas protection atmosphere, weigh 0.0156 g of p-cymene dichloride ruthenium (II) dimer and dissolve it in 40 ml of tetrahydrofuran solvent, add 1.0 g of the above-mentioned preparation containing triphenylphosphine and sodium sulfonate Porous organic copolymer, stirred for 24 hours. Subsequently,...

Embodiment 2

[0030] In Example 2, in addition to weighing 0.078 gram of p-cymene dichloride ruthenium (II) dimer to replace 0.0156 gram of p-cymene dichloride ruthenium (II) dimer, the remaining catalyst preparation process and implementation Example 1 is the same.

Embodiment 3

[0032] In Example 3, except that 0.03 g of palladium acetate was weighed instead of 0.0156 g of p-cymene dichloride ruthenium (II) dimer, the rest of the catalyst preparation process was the same as in Example 1.

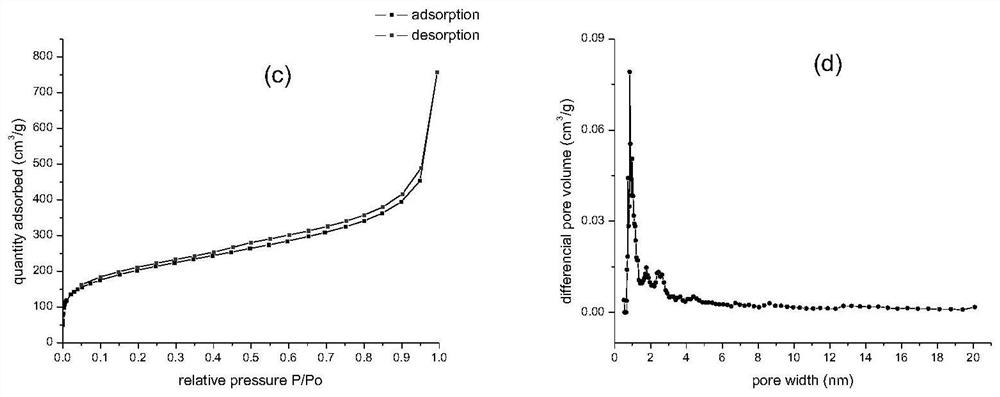

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com