Silicon composite material, preparation method thereof, negative plate and lithium ion battery

A technology of silicon composite materials and carbon materials, applied in the direction of nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc., can solve the large problems of conductive network and hollow structure stability, which is not conducive to the silicon material industry issues such as popularization, cycle performance and safety performance need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

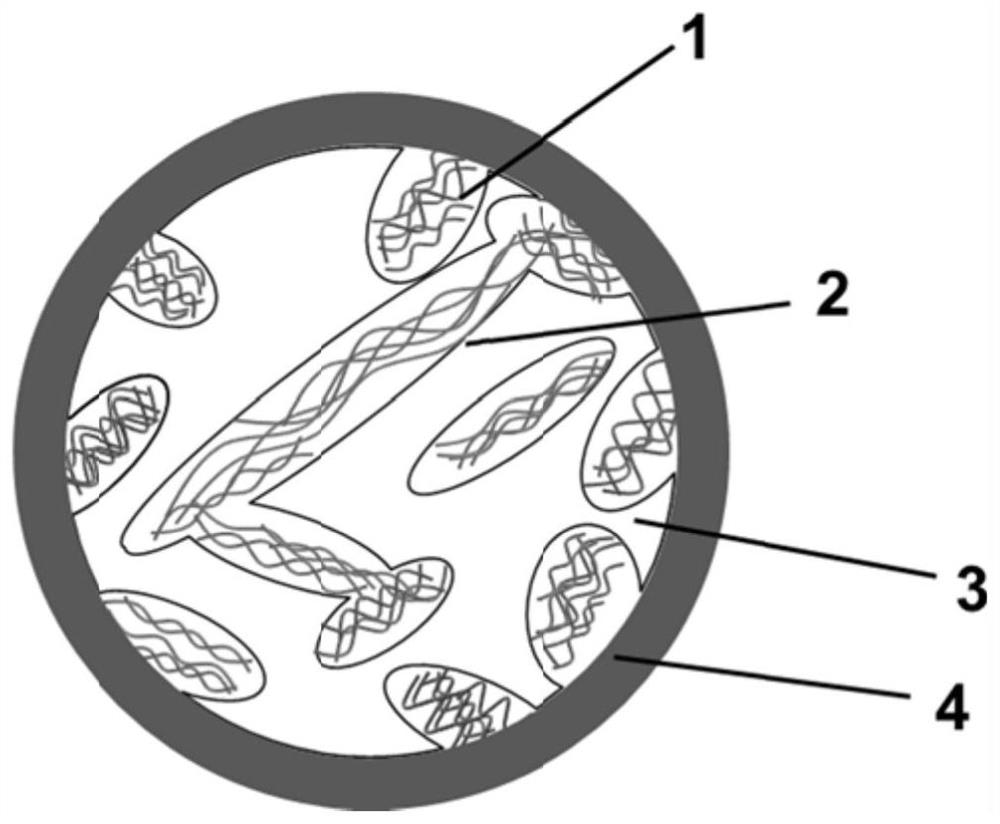

[0085] This embodiment provides a silicon composite material, the preparation method of which is as follows:

[0086] S1: Put a silicon-nickel alloy with a total content of 10mol (the atomic ratio of silicon and nickel is 9:1) in 1.5L of hydrochloric acid solution with a concentration of 1mol / L, and immerse it for 2h to remove part of the metal in the silicon-nickel alloy to form a Through-hole silicon with holes, and some metal remains in the through-hole silicon as a catalyst for growing one-dimensional carbon materials;

[0087] S2: Dry the through-hole silicon and place it in a tube furnace, and feed a mixed gas of methane and nitrogen with a gas flow rate of 100mL / min, wherein methane accounts for 10% of the gas flow, and nitrogen accounts for 90% of the gas flow. Generate a one-dimensional carbon material that runs through the channels of through-hole silicon to obtain intermediate products;

[0088] S3: Put the intermediate product in a 2mg / mL dopamine hydrochloride-tr...

Embodiment 2

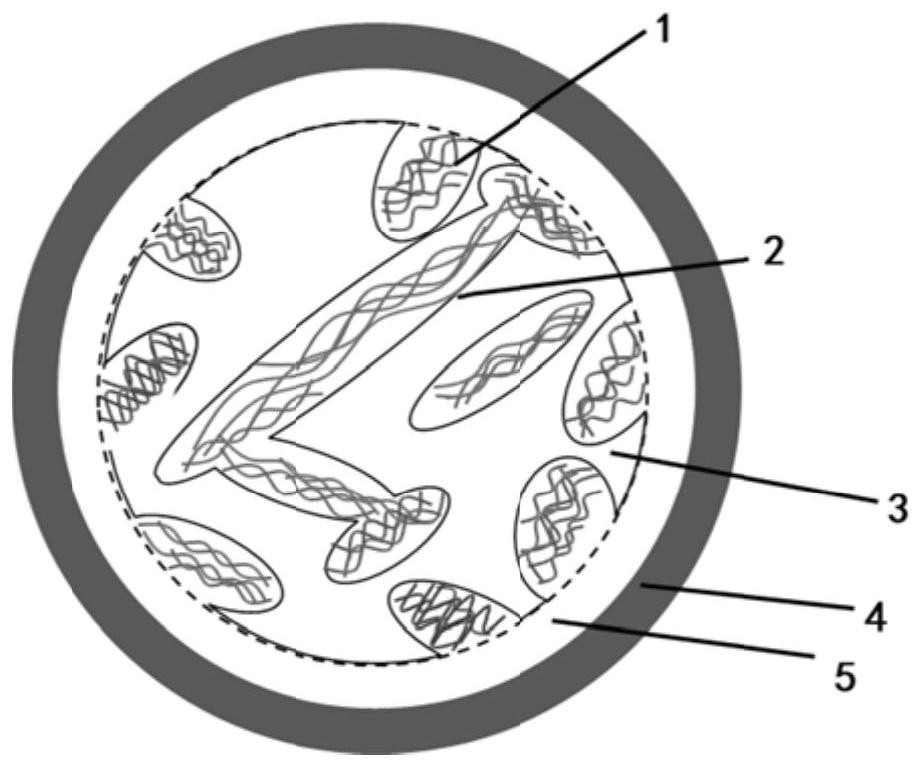

[0094] This embodiment provides a silicon composite material, the preparation method of which is as follows:

[0095] S1: Put the silicon-aluminum-iron alloy with a total content of 10mol (the atomic ratio of silicon, aluminum and iron is 6:2:2) in 3L of hydrochloric acid solution with a concentration of 2mol / L, and immerse it for 2h to remove part of the metal in the silicon-aluminum-iron alloy , form through-hole silicon with channels, and at the same time, some metal remains in the through-hole silicon as a catalyst for growing one-dimensional carbon materials;

[0096] S2: Dry the through-hole silicon and place it in a tube furnace, and feed a mixed gas of ethylene and argon with a gas flow rate of 200mL / min, wherein ethylene accounts for 10% of the gas flow, and argon accounts for 90% of the gas flow. In-situ generation of one-dimensional carbon materials penetrating through the channels of through-hole silicon to obtain intermediate products;

[0097] S3: Put the interm...

Embodiment 3

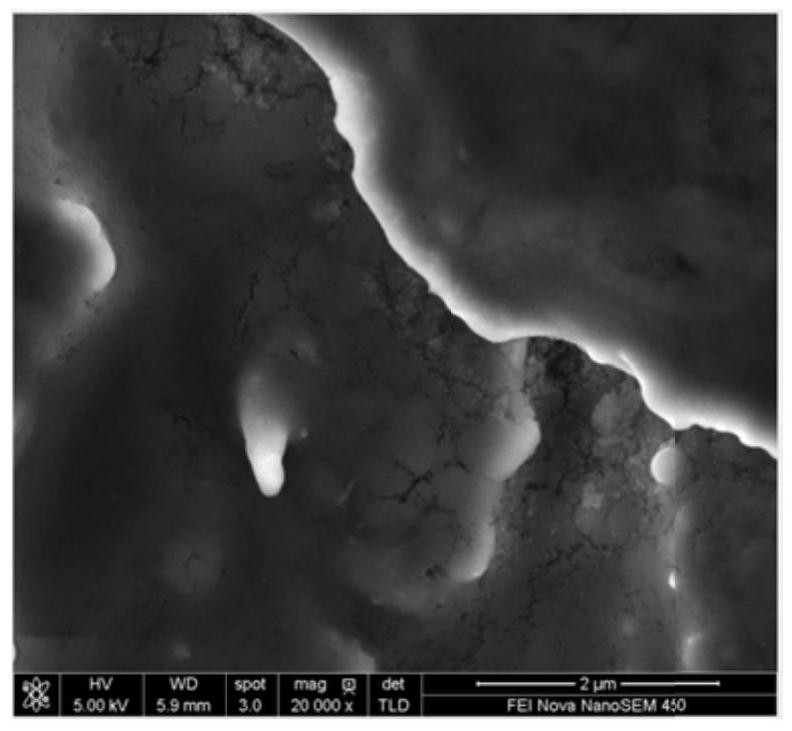

[0103] This embodiment provides a silicon composite material, the preparation method of which is as follows:

[0104] S1: Put the silicon-iron-copper alloy with a total content of 10mol (the atomic ratio of silicon, iron and copper is 4:4:2) in 4L of hydrochloric acid solution with a concentration of 2mol / L, and immerse it for 2h to remove the silicon-iron-copper alloy. Part of the metal forms through-hole silicon with channels, and some metal remains in the through-hole silicon as a catalyst for growing one-dimensional carbon materials;

[0105] S2: Dried the through-hole silicon and placed it in a tube furnace, and introduced a mixed gas of propylene and argon with a gas flow rate of 200mL / min, wherein propylene accounted for 10% of the gas flow rate, and argon gas accounted for 90% of the gas flow rate. In-situ generation of a one-dimensional carbon material penetrating through the pores of through-hole silicon to obtain an intermediate product, which is then placed in an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com