Single battery voltage inconsistency fault prediction method and device and server

A fault prediction and single battery technology, which is applied in battery/fuel cell control devices, forecasting, electric vehicles, etc., can solve the problems of inability to effectively monitor the health status of power batteries, potential safety hazards that cannot be discovered in time, and power battery voltage imbalances, etc. problem, to achieve the effect of effective monitoring of battery health status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

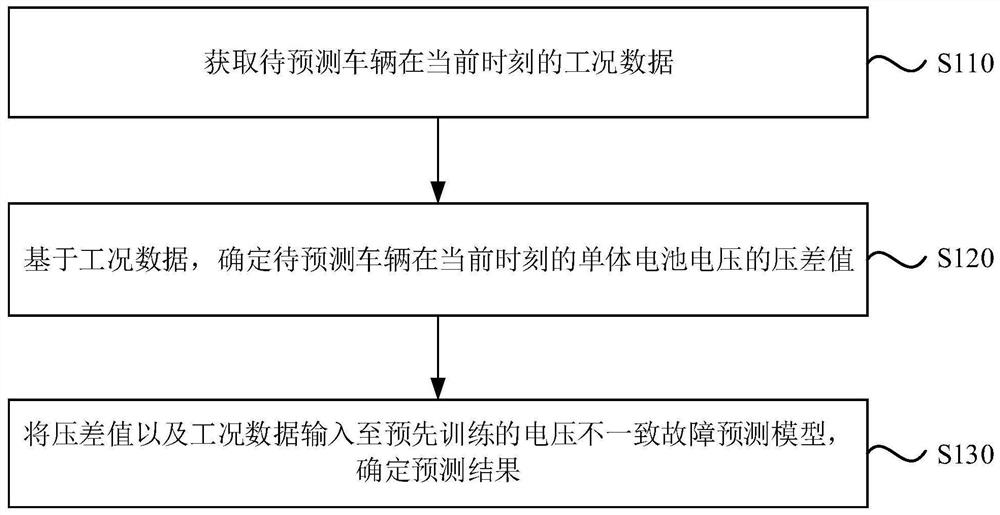

[0029] figure 1 It is a schematic flow chart of a single battery voltage inconsistent fault prediction method provided in Embodiment 1 of the present invention. This embodiment is applicable to the situation of predicting single battery voltage inconsistent faults. The fault prediction device can be implemented, and the device can be implemented in the form of software and / or hardware, and the hardware can be a server or the like.

[0030] Such as figure 1 As described, the method of this embodiment specifically includes the following steps:

[0031] S110. Acquire working condition data of the vehicle to be predicted at the current moment.

[0032] Wherein, the vehicle to be predicted may be a vehicle that the user is driving, or may be a vehicle driving on a road or parked on a roadside, and the like. The battery pack used in the vehicle to be predicted includes at least two battery cells, and the specific number of the single cells is not limited. The working condition d...

Embodiment 2

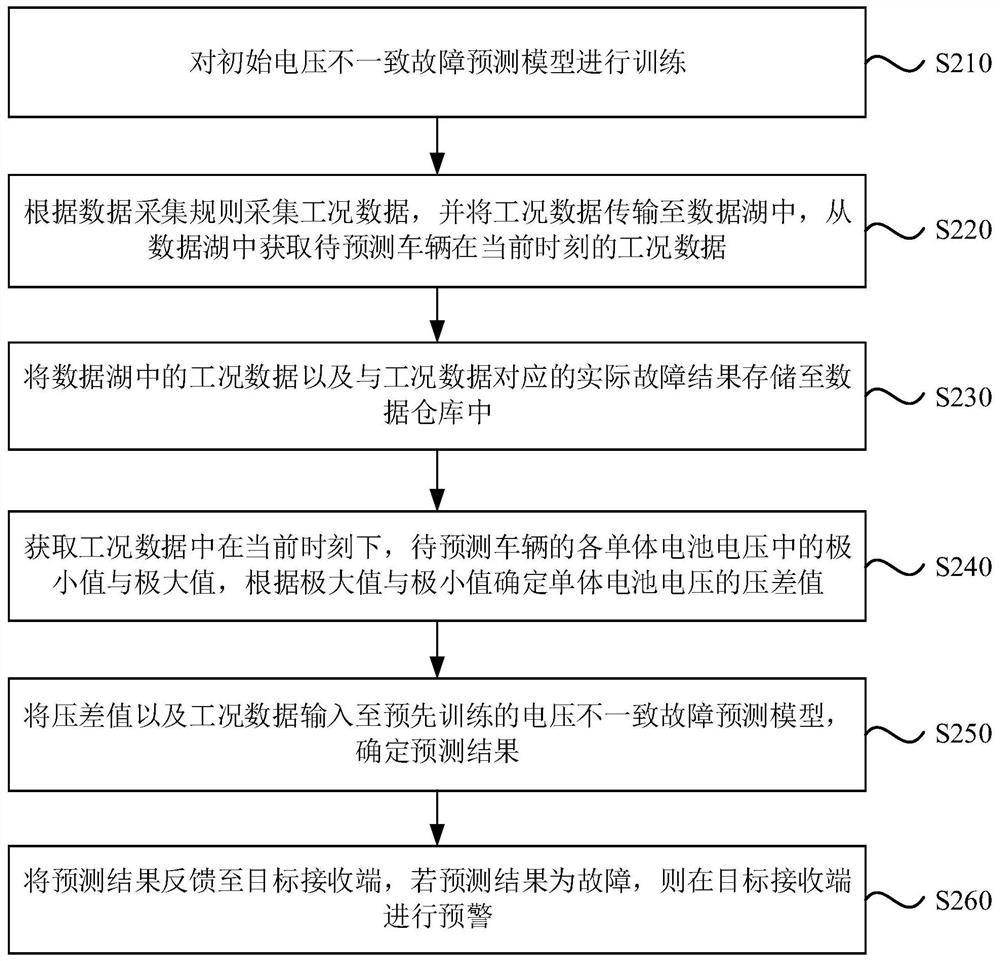

[0044] figure 2 It is a schematic flowchart of a single battery voltage inconsistent fault prediction method provided in Embodiment 2 of the present invention. This embodiment is based on the above-mentioned embodiments, and the training method for the voltage inconsistent fault prediction model can be referred to in this embodiment. Technical solutions. Wherein, explanations of terms that are the same as or corresponding to the above embodiments are not repeated here.

[0045] Such as figure 2 As shown, the method specifically includes the following steps:

[0046] S210. Train the initial voltage inconsistent fault prediction model.

[0047] Specifically, in order to make the prediction result of the voltage inconsistent fault prediction model accurate, the initial voltage inconsistent fault prediction model can be trained through the following steps.

[0048] Step 1. Obtain the historical operating condition data corresponding to the vehicle to be predicted and the lab...

Embodiment 3

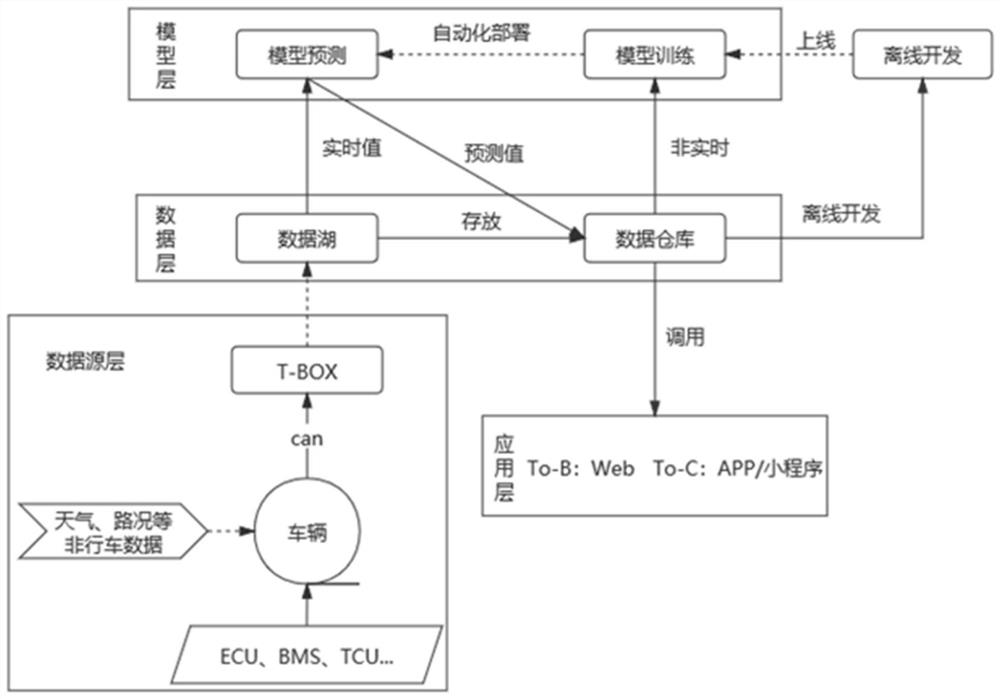

[0082] image 3 It is a schematic diagram of a single battery voltage inconsistent fault prediction logic framework provided by Embodiment 3 of the present invention. This embodiment is applicable to the situation of predicting single battery voltage inconsistent faults, wherein the same as the above-mentioned embodiments or The explanation of the corresponding terms will not be repeated here.

[0083] Such as image 3 As shown, the fault prediction logic architecture of single battery voltage inconsistency mainly includes four parts: data source layer, data layer, model layer and application layer.

[0084] The data source layer is composed of vehicle data and peripheral data. The data source layer is mainly responsible for data collection and fusion to form a signal upload list, and finally upload the signal upload list through the car cloud protocol.

[0085] Among them, the on-board data includes but not limited to the data collected by the following sensors / actuators: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com