Multichannel carbon dioxide concentration automatic surveying device of grain piles in grain bin

A carbon dioxide and multi-channel technology, applied in the direction of material electrochemical variables, analysis materials, instruments, etc., can solve the problems of hazard inspection and confirmation, long time for ventilation, large volume of gas collection pipe, etc., to achieve accurate carbon dioxide concentration, gas The effect of reducing the tightness inspection and facilitating the maintenance of electrical appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

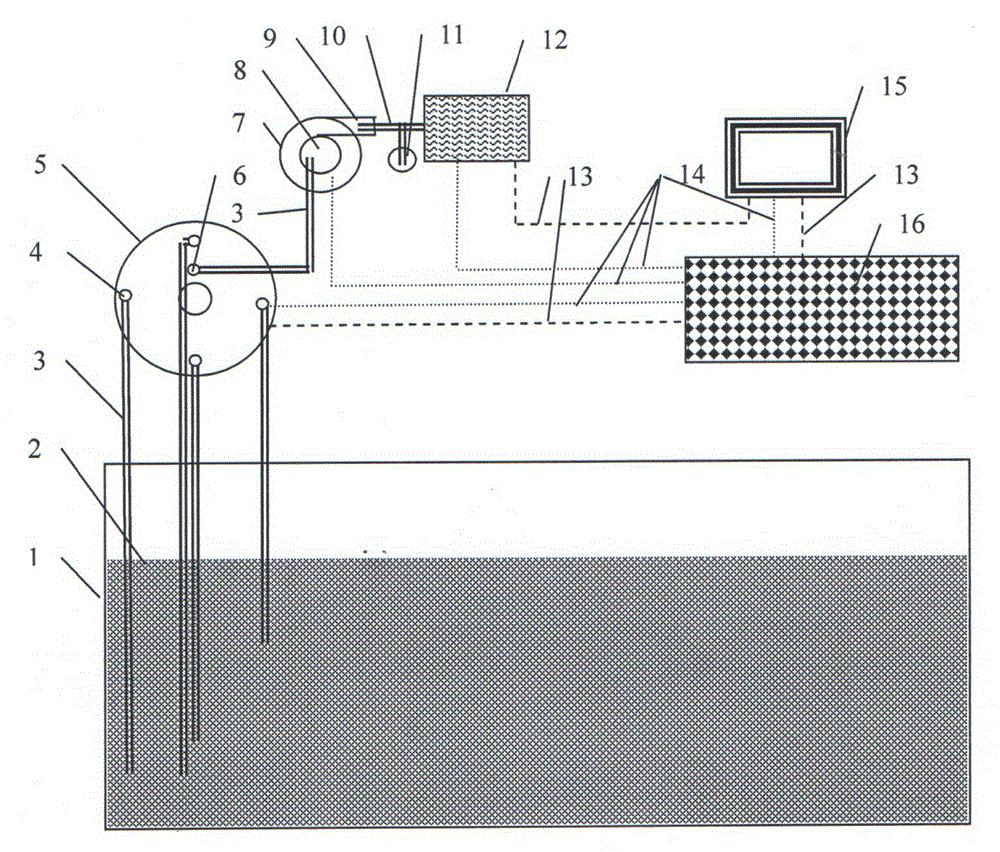

[0028] The present invention will be further described in conjunction with the following embodiments (accompanying drawings—take the automatic inspection of carbon dioxide concentration in grain piles at four monitoring points as an example):

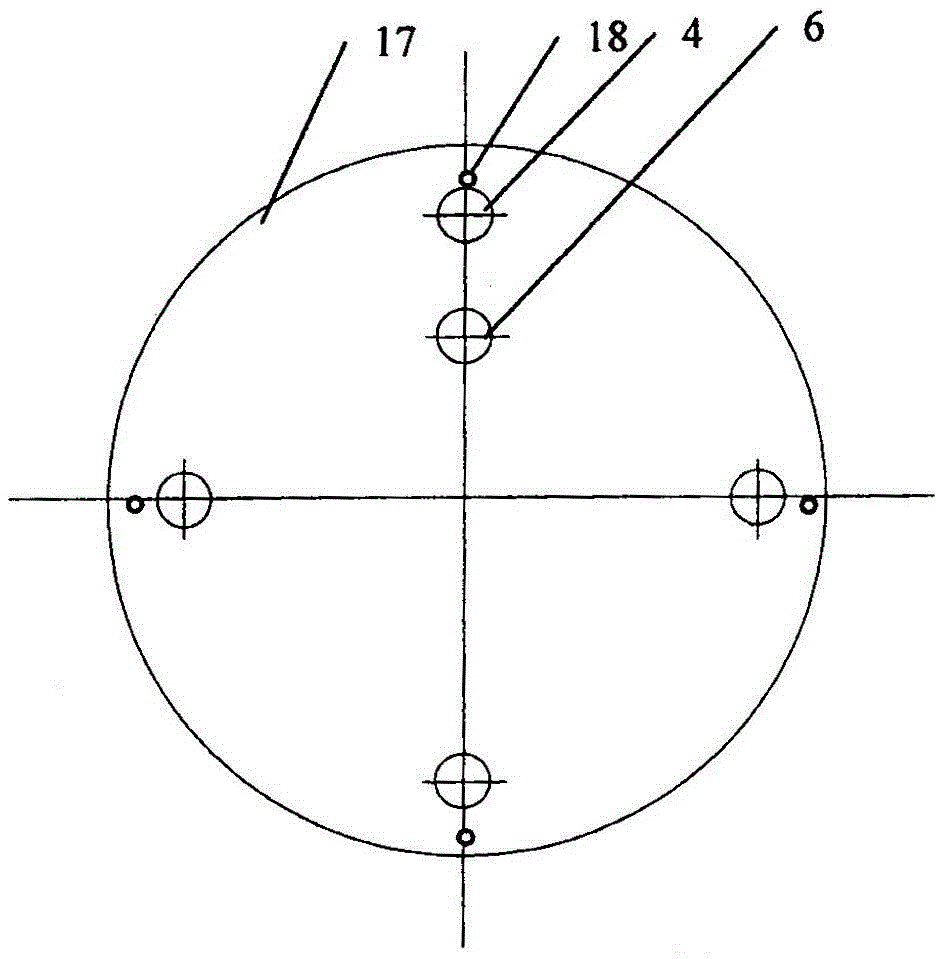

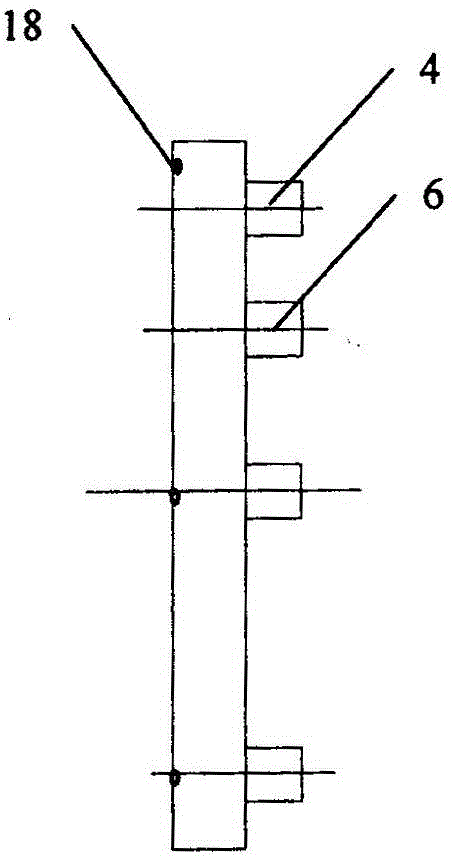

[0029] Such as figure 1 As shown, the multi-channel carbon dioxide concentration automatic monitoring device for grain piles in the granary of the present invention includes a plurality of gas pipelines 3 connected to the gas detection device 5 installed in the grain pile in the granary, and the gas detection device 5 is composed of The fixed disc 17 and the rotary disc 19 combined in an airtight manner driven by a stepping motor are composed; around the fixed disc 17, there are air intake holes equal in number to the gas pipelines in an evenly distributed manner, and are connected with the rotary disc 19 The other side of the combination surface is installed with the inlet port gas nozzle 4 communicating with the air inlet and the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com