Engine oil rail joint oil hole fault detection system and method

A fault detection and engine technology, applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve problems such as fracture or chipping, misplacement, blockage of oil holes, etc., to prevent defective products from appearing , the effect of making up for its own shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a description of this work in conjunction with the accompanying drawings:

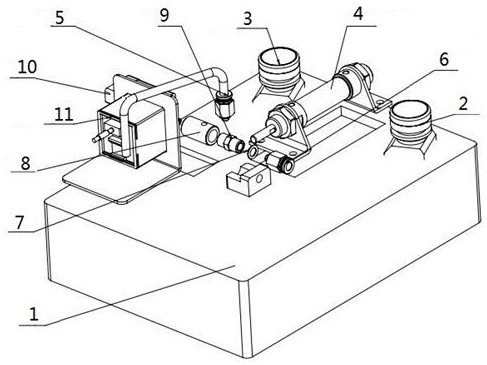

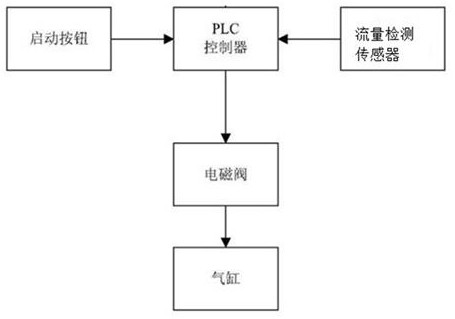

[0019] refer to figure 1 , now optimize the processing technology to increase the oil hole diameter detection link, add a detection tool, the oil rail joint 9 is fixed on the tooling bottom plate 1, and the inlet pipe air pipe joint 6 and the air outlet pipe air pipe joint 5 are docked on the left and right sides of the oil hole, Wherein one end of the outlet pipe trachea joint 5 is connected to a micro-gas flow detection sensor 11 at the outlet pipe, and the flow detection sensor 11 is connected with an alarm lamp and a cylinder actuator to form a complete detection system.

[0020] The cylinder actuator includes a clamping head 8 and a clamping cylinder 10; wherein the clamping head 8 is provided with an air outlet, and the outlet pipe trachea joint 5 is connected to the air outlet of the clamping head 8.

[0021] After adding a detection tool, the high-pressure gas 0.5kpa en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com