Three-way impact acceleration sensor installation mode validity test system and method

A technology of acceleration sensor and installation method, which is applied in multi-dimensional acceleration measurement, velocity/acceleration/shock measurement, acceleration measurement using inertial force, etc. It can solve the problems affecting the normal evaluation of the impact resistance performance of spacecraft, and achieves a small footprint , Portable and simple, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

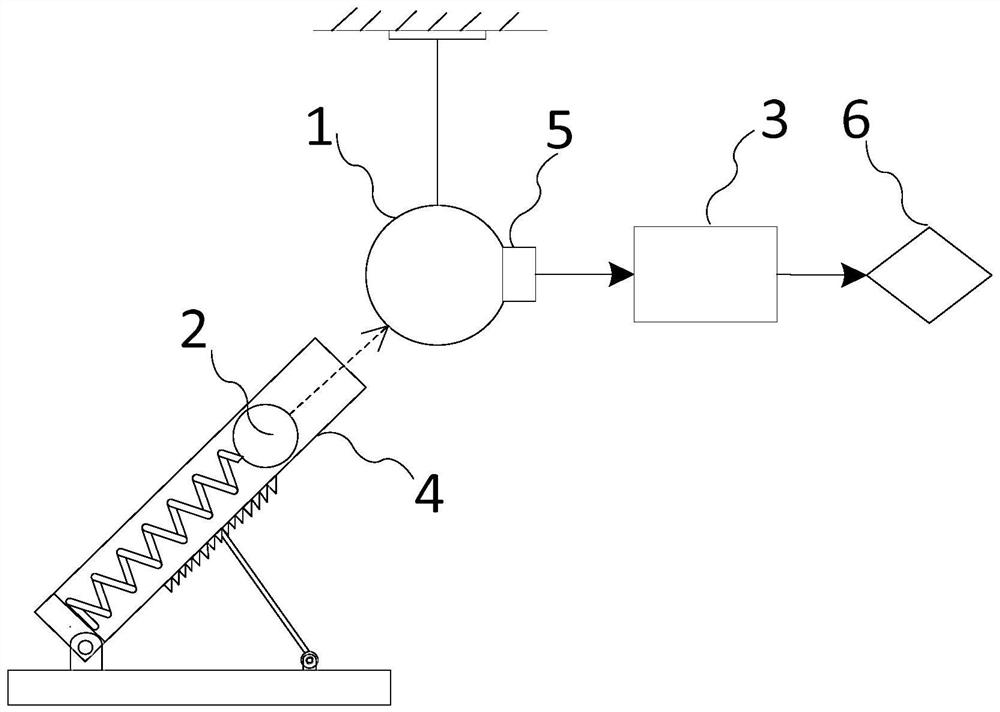

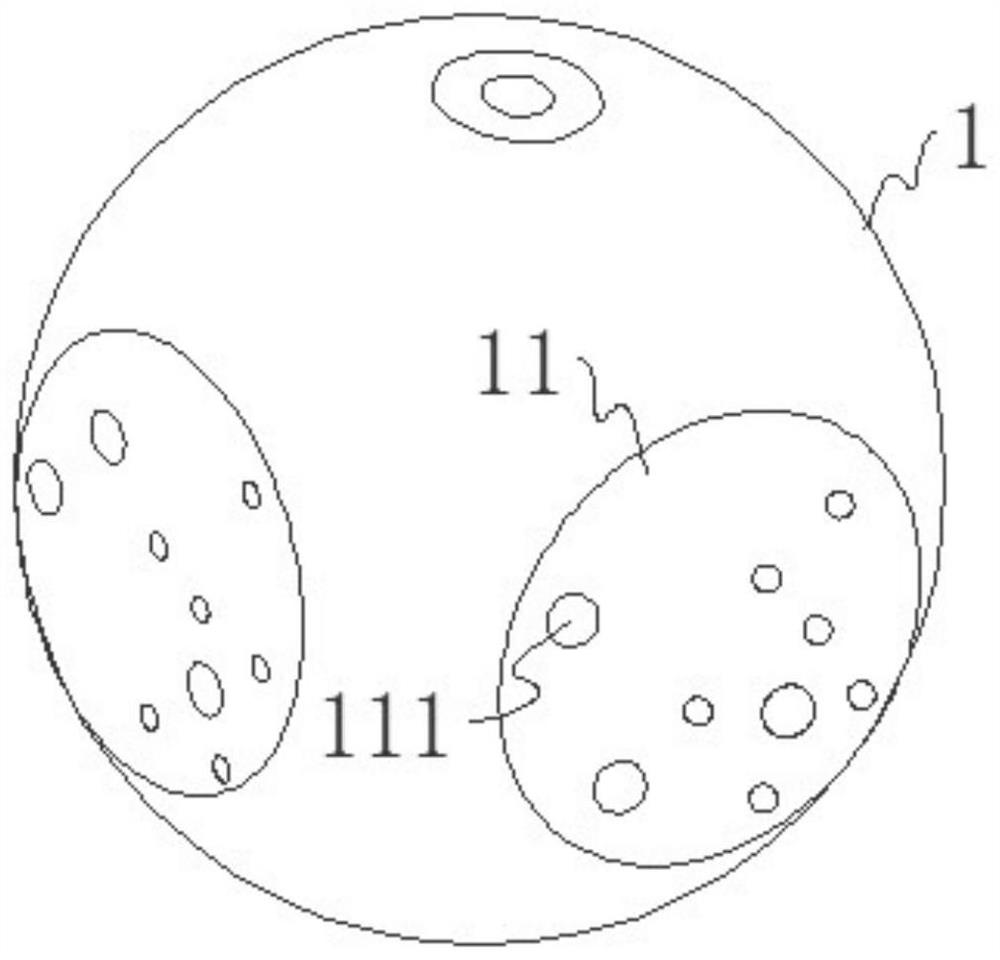

[0033] Such as figure 1 As shown, the present embodiment relates to a system for checking the validity of the three-way shock acceleration sensor 5 installation method, including a test ball 1, an excitation ball 2, a data acquisition system 3, a launch device 4, and a sensor installation validity analysis unit 6; A three-way impact acceleration sensor 5 is installed on the inspection ball 1; the excitation ball 2 is used to impact the inspection ball 1; the launching device 4 is used to launch the excitation ball 2 in a specified direction and speed; the data acquisition system 3 and The three-way impact acceleration sensors 5 are signal-connected for collecting the data measured by each three-way impact acceleration sensors 5; the sensor installation effectiveness analysis unit 6 adopts a data analysis method to perform data processing on the measured impact data, In this way, the effectiveness of the sensor installation method is evaluated.

[0034] In this embodiment, the...

Embodiment 2

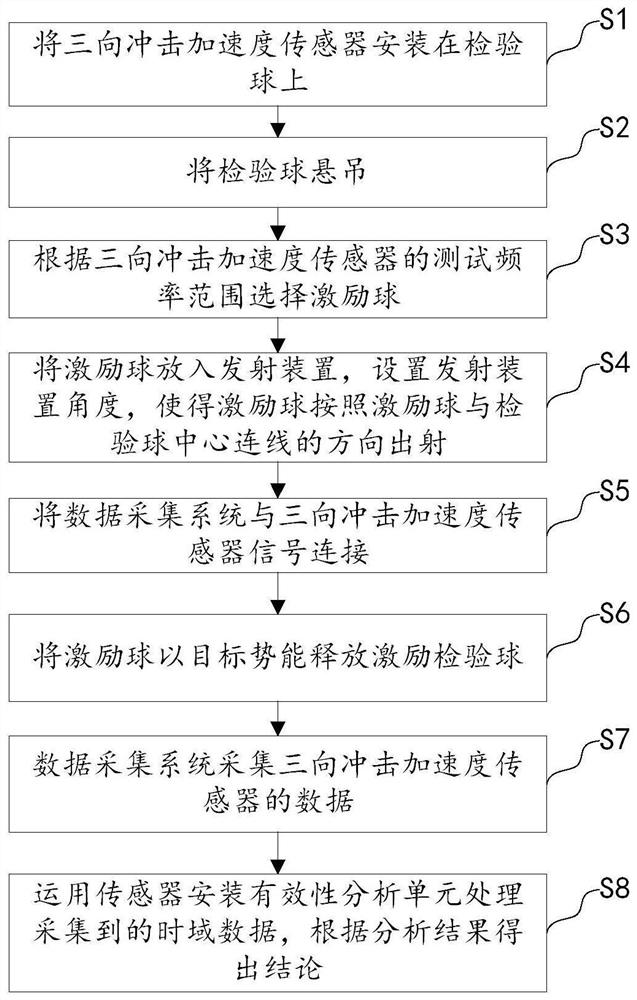

[0044] Such as image 3 As shown, this embodiment relates to a method for checking the validity of the installation method of a three-way impact acceleration sensor. This embodiment uses the inspection system of Embodiment 1 for inspection, including the following steps:

[0045] S1. Install the three-way impact acceleration sensor on the test ball.

[0046] In this step, two three-way impact acceleration sensors of the same type can be installed on the installation plane of the test ball in two ways: direct installation and installation through the mounting seat, or different types of three-way impact acceleration sensors can be installed in the same way. Install on the installation plane, or install different types of three-way impact acceleration sensors on the installation plane in different installation methods.

[0047] S2, suspending the inspection ball.

[0048] The test ball is hoisted and suspended together with the three-way impact acceleration sensor installed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com