Cordierite-doped multiphase microwave dielectric ceramic material as well as preparation method and application thereof

A microwave dielectric ceramic and cordierite technology, which is applied in the field of 5G microwave dielectric ceramic materials, can solve problems such as failure and peeling of microwave dielectric ceramic devices, and achieve the effects of good application prospects, controllable process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

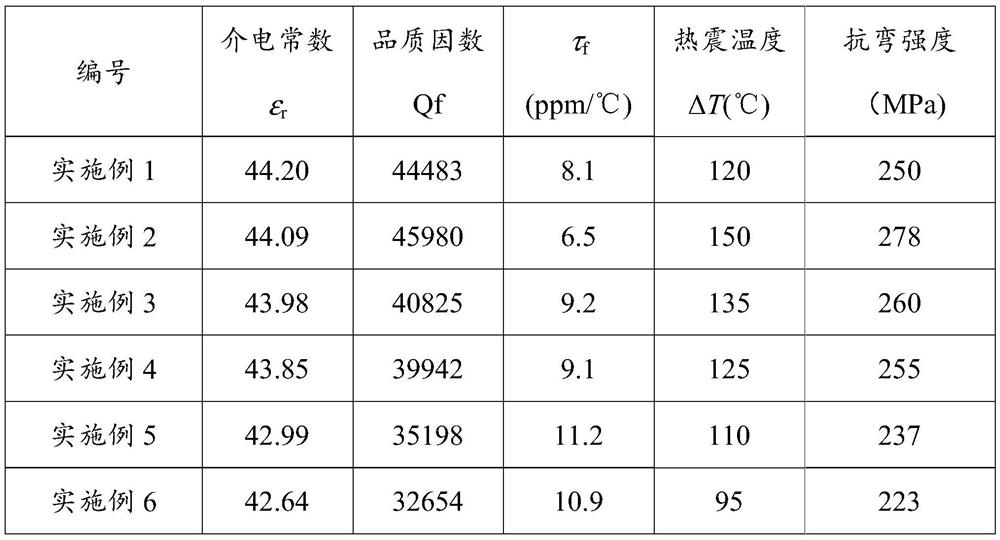

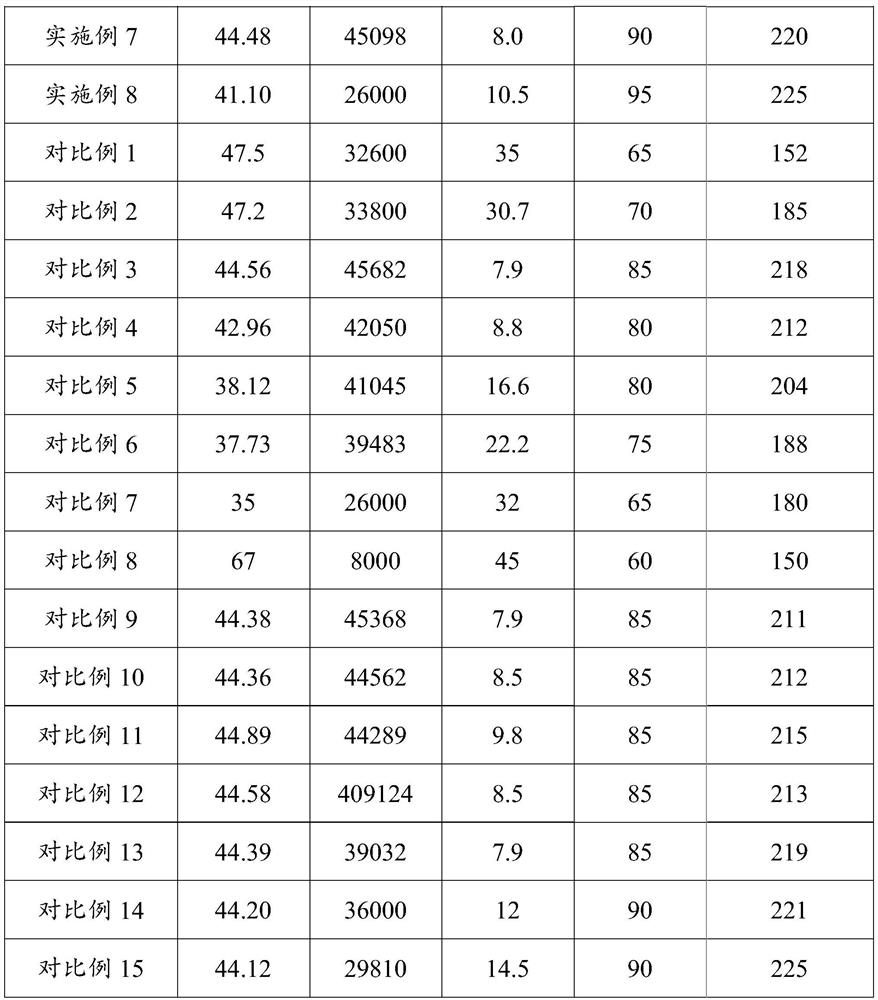

Examples

Embodiment 1

[0077] This embodiment provides a composite microwave dielectric ceramic material doped with cordierite, which consists of 99.45wt% main material CaTiO 3 -SmAlO 3 , 0.5wt% cordierite and 0.05wt% sintering aid Y 2 o 3 production.

[0078] (1) Main material CaTiO 3 -SmAlO 3 The preparation steps are as follows: Weigh 34wt% TiO 2 , 31wt% Sm 2 o 3 , 25wt% CaO and 10wt% Al 2 o 3 The mixture is prepared by batching, and the mixture, yttrium-stabilized zirconium balls and deionized water are placed in a ball mill tank at a mass ratio of 1:5:3 for ball milling, and the ball milling time is 5 hours. The slurry obtained by ball milling was dried at 100° C. for 20 hours, and then passed through a 100-mesh sieve to obtain the main material powder. The main material powder was pre-sintered in a high-temperature box furnace for 3 hours, and the pre-sintering temperature was 1200 ° C to obtain the main material CaTiO 3 -SmAlO 3 .

[0079] (2) The preparation steps of cordierite ...

Embodiment 2

[0082] This embodiment provides a composite microwave dielectric ceramic material doped with cordierite. The difference from Embodiment 1 is that the main material is CaTiO 3 -SmAlO 3 content of 99.15wt%, cordierite content of 0.8wt% and sintering aid Y 2 o 3 The content is 0.05wt%, and the rest of the raw materials and steps are the same as in Example 1, and will not be repeated here.

Embodiment 3

[0084] This embodiment provides a composite microwave dielectric ceramic material doped with cordierite. The difference from Embodiment 1 is that the main material is CaTiO 3 -SmAlO 3 content of 98.95wt%, cordierite content of 1wt% and sintering aid Y 2 o 3 The content is 0.05wt%, and the rest of the raw materials and steps are the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com