Fabricated aluminum-calcium composite board material as well as preparation method and application thereof

A composite board, prefabricated technology, used in covering/lining, construction, building structure, etc., can solve the problems of degumming, inability to adjust the size, etc., to achieve the effect of improving the assembly rate, accurate size, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

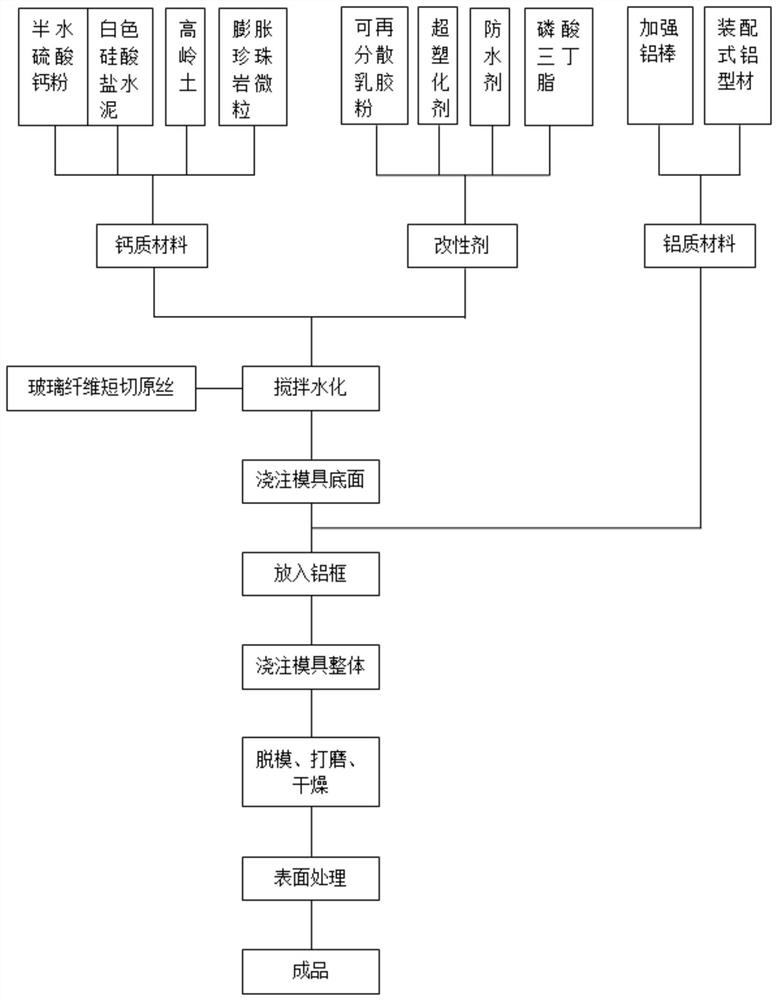

Method used

Image

Examples

Embodiment 1

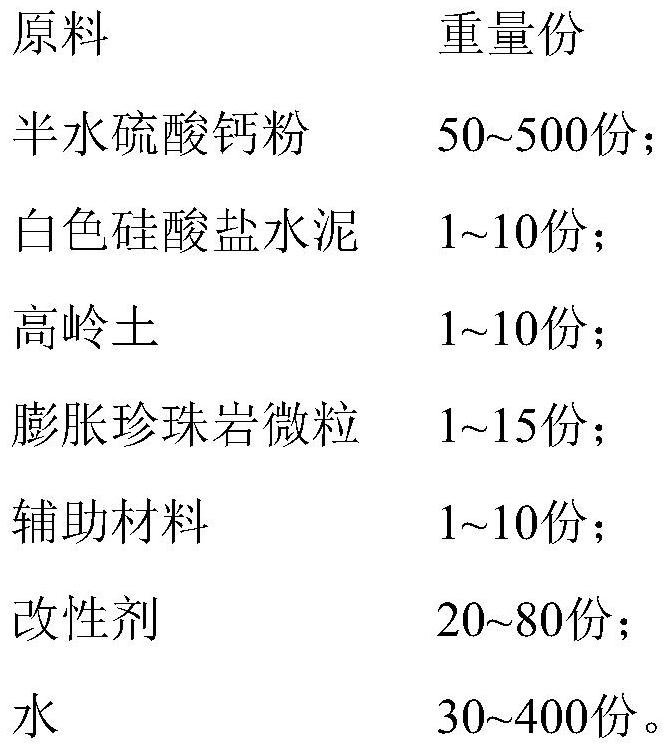

[0045] An assembled aluminum-calcium composite board material, the aluminum-calcium composite board material is composed of calcium material and aluminum material, and the calcium material contains raw materials with the following weight:

[0046]

[0047] The modifier comprises raw materials by weight of:

[0048]

[0049] Further, the preparation method of the aluminum material includes the following steps:

[0050] (1) Cut the aluminum profiles into small sections and weld them into a rectangular aluminum frame;

[0051] (2) Fix the aluminum rod inside the rectangular aluminum frame to strengthen the strength of the aluminum frame and improve its deformation degree.

[0052] The present invention also provides a method for preparing the above-mentioned assembled aluminum-calcium composite board material, the preparation method comprising the following steps:

[0053] (1) Preparation of latex liquid: redispersible latex powder and water are prepared in proportion, an...

Embodiment 2

[0065] An assembled aluminum-calcium composite board material, the aluminum-calcium composite board material is composed of calcium material and aluminum material, and the calcium material contains raw materials with the following weight:

[0066]

[0067] The modifier comprises raw materials by weight of:

[0068]

[0069] Further, the preparation method of the aluminum material includes the following steps:

[0070] (1) Cut the aluminum profiles into small sections and weld them into a rectangular aluminum frame;

[0071] (2) Fix the aluminum rod inside the rectangular aluminum frame to strengthen the strength of the aluminum frame and improve its deformation degree.

[0072] The present invention also provides a method for preparing the above-mentioned assembled aluminum-calcium composite board material, the preparation method comprising the following steps:

[0073] (1) Preparation of latex liquid: redispersible latex powder and water are prepared in proportion, an...

Embodiment 3

[0085] An assembled aluminum-calcium composite board material, the aluminum-calcium composite board material is composed of calcium material and aluminum material, and the calcium material contains raw materials with the following weight:

[0086]

[0087]

[0088] The modifier comprises raw materials by weight of:

[0089]

[0090] Further, the preparation method of the aluminum material includes the following steps:

[0091] (1) Cut the aluminum profiles into small sections and weld them into a rectangular aluminum frame;

[0092] (2) Fix the aluminum rod inside the rectangular aluminum frame to strengthen the strength of the aluminum frame and improve its deformation degree.

[0093] The present invention also provides a method for preparing the above-mentioned assembled aluminum-calcium composite board material, the preparation method comprising the following steps:

[0094] (1) Preparation of latex liquid: redispersible latex powder and water are prepared in pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com