Phosphate slag waterproof plastering mortar and mortar plastering waterproof construction method

A technology of plastering mortar and construction method, which is applied in the field of waterproof plastering mortar for phosphate slag and mortar plastering and waterproof construction, and can solve the problems of reduced activity and little research on the application of phosphate slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

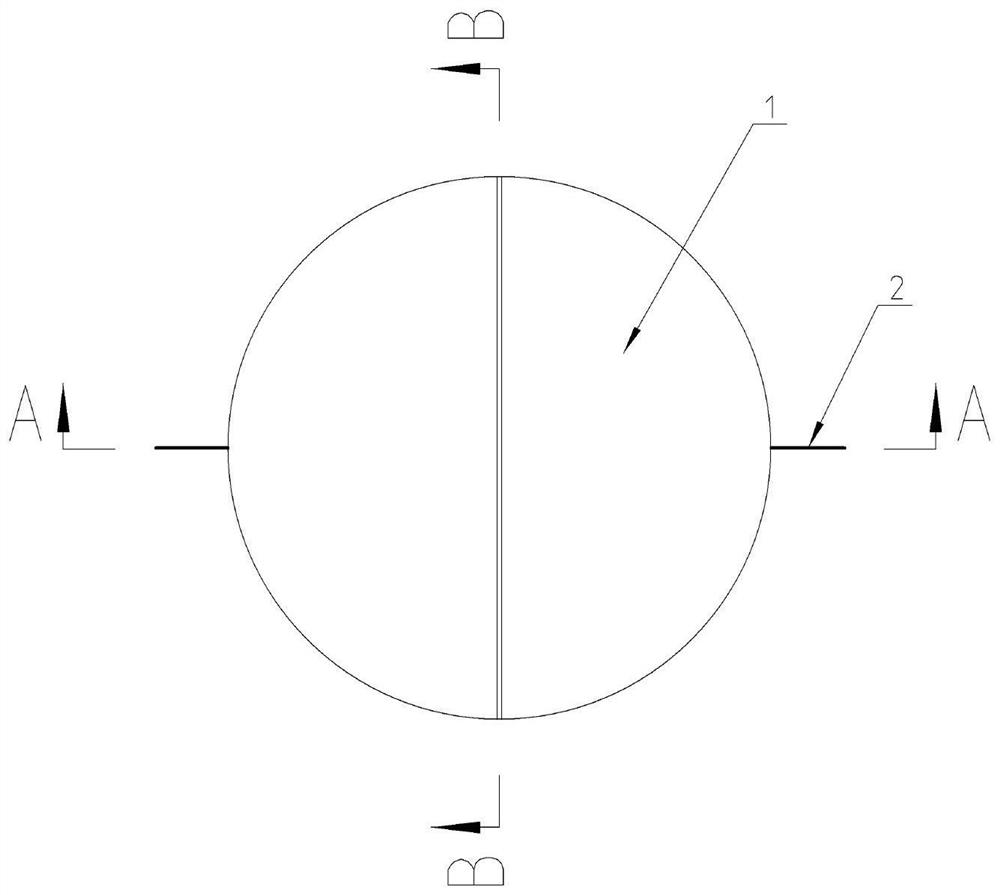

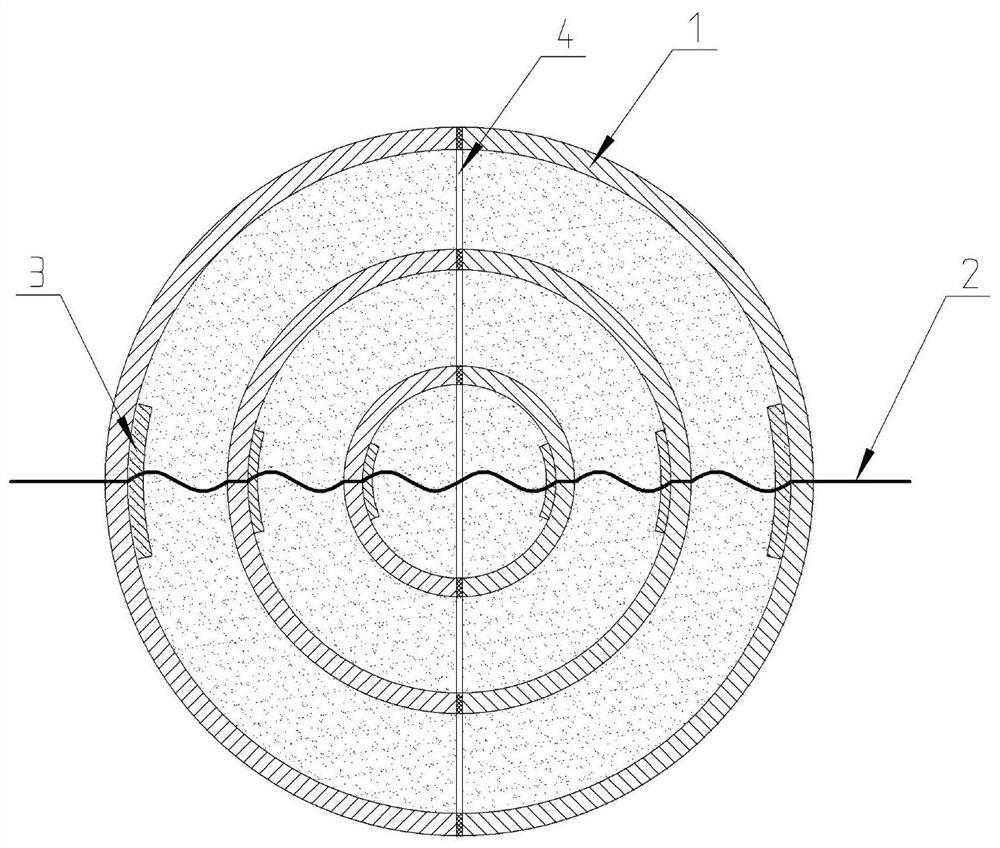

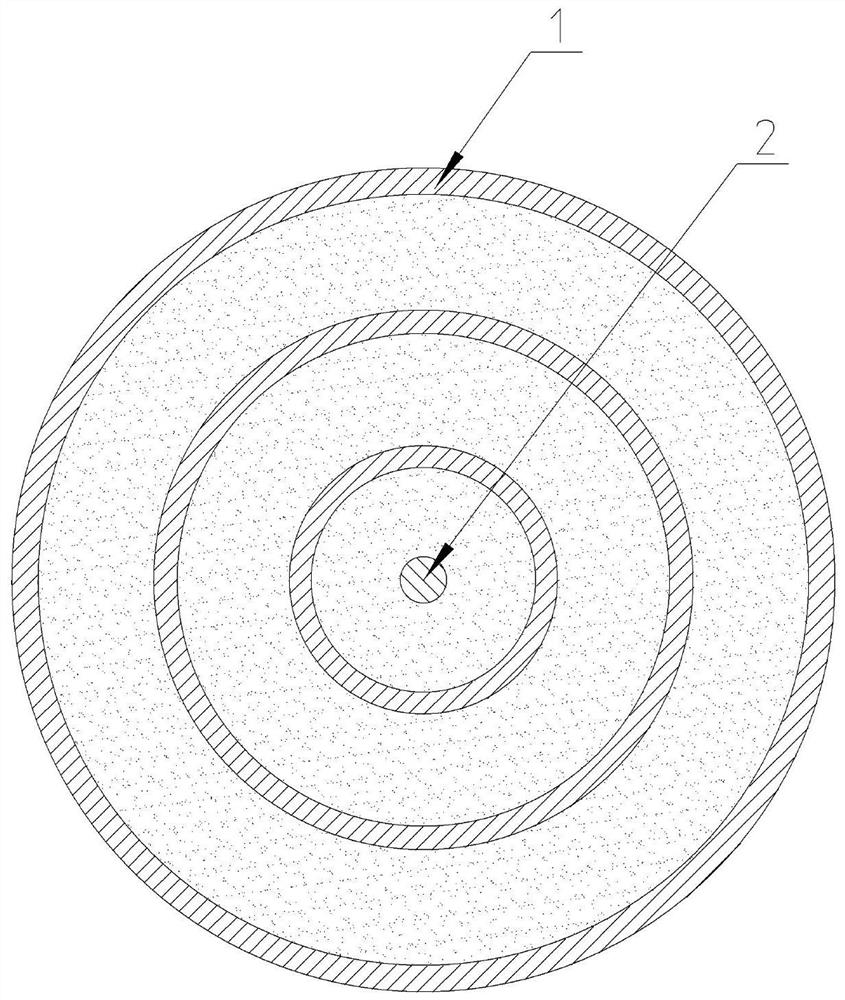

Image

Examples

Embodiment 1

[0063] The dry powder mortar is calculated in parts by mass, including 100 catties of cement, 250 catties of sand, 50 catties of phosphate slag, 7 catties of inorganic silicon structure self-waterproof additive and 4 catties of repairing spheres.

[0064] Wherein the inorganic siliceous structure self-waterproofing additive is made up of the raw material of following percentage by weight: active silicon dioxide 68%, alkali-soluble aluminum oxide 8%, auxiliary agent is 24%, auxiliary agent is made of Fe 2 o 3 , NaCl and MgO mixed.

Embodiment 2

[0066] The dry powder mortar is calculated in parts by mass, including 100 catties of cement, 220 catties of sand, 30 catties of phosphate slag, 7 catties of inorganic silicon structure self-waterproof additive and 4 catties of repairing spheres.

[0067] Wherein the inorganic siliceous structure self-waterproofing additive is made up of the raw material of following percentage by weight: active silicon dioxide 78%, alkali-soluble aluminum oxide 9.5%, auxiliary agent is 12.5%, auxiliary agent is made of Fe 2 o 3 , NaCl and MgO mixed.

Embodiment 3

[0069] The dry powder mortar is calculated in parts by mass, including 100 catties of cement, 280 catties of sand, 70 catties of phosphate slag, 6 catties of inorganic silicon structure self-waterproof additive and 3 catties of repairing spheres.

[0070] The self-waterproofing additive with an inorganic siliceous structure is composed of the following raw materials in weight percent: 74.5% of active silicon dioxide, 16% of alkali-soluble aluminum oxide, and 9.5% of additives, which are made by mixing Fe2O3, NaCl and MgO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com