Industrial wastewater treatment process

A technology for treating process and industrial wastewater, which is applied in the direction of food industry wastewater treatment, water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problem of difficulty in separating suspended solids, reduce the speed of odor emission, and purify the work Environment, reduce the effect of endothermic explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

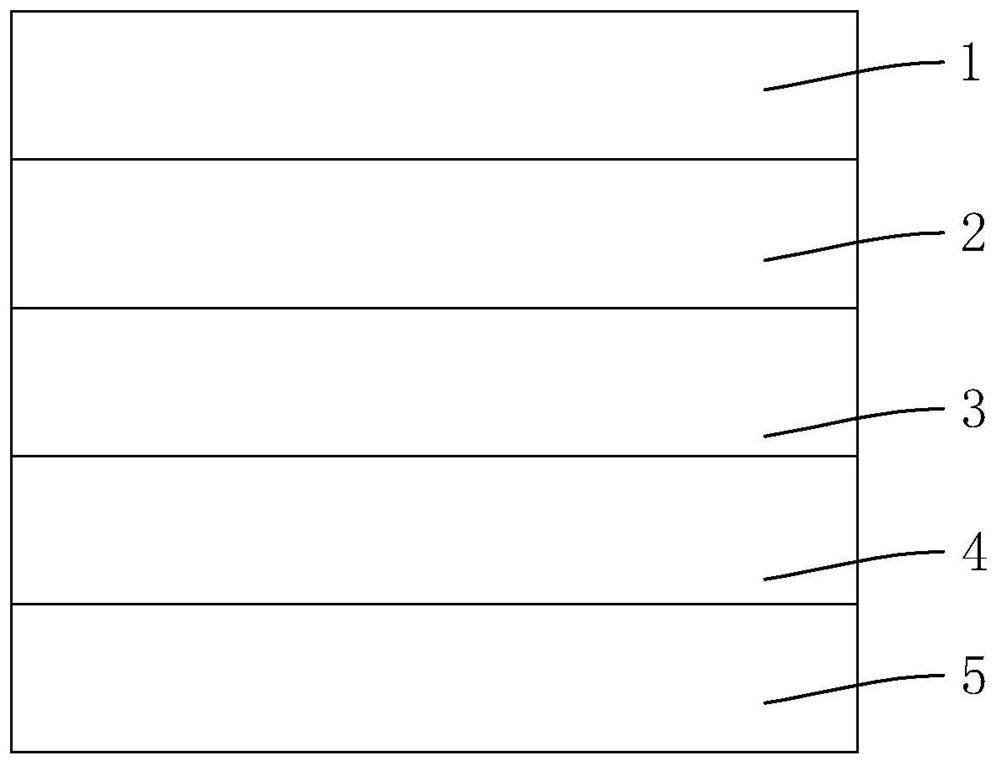

[0036] Embodiment 1: A kind of industrial wastewater treatment process, the sewage is passed into the grid, the air flotation tank, the adjustment tank, the anaerobic tank, the aerobic tank, the inclined tube sedimentation tank in sequence, and then discharged, wherein the grid, the adjustment tank, the anaerobic The treatment process of pond, aerobic pond and inclined tube sedimentation pond are all prior art, and will not repeat them here.

[0037] The principle of the air flotation tank is: use a large number of micro-bubbles to capture and absorb fine particles of sticky matter (that is, suspended matter) to float up to achieve the effect of solid-liquid separation.

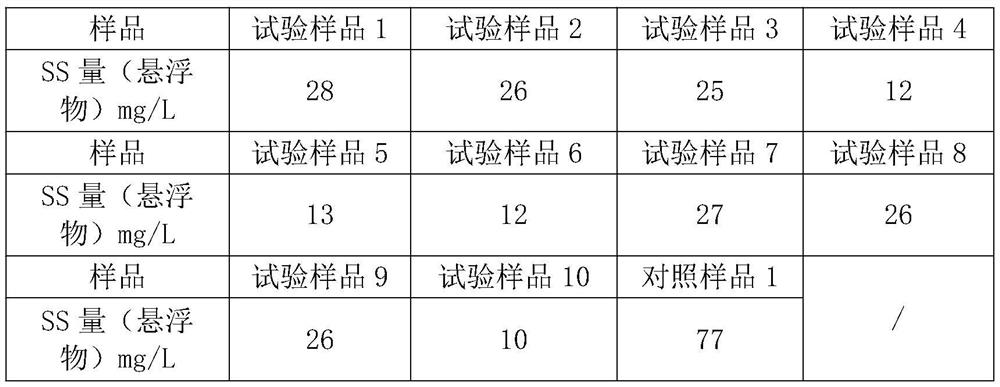

[0038] The material that can generate a large number of microbubbles in the air flotation tank is the air flotation agent. The air flotation agent in the prior art is generally air. The air flotation agent in this embodiment is liquid nitrogen. The volume ratio of liquid nitrogen to sewage for 1:30. When the...

Embodiment 2

[0041] Example 2: An industrial wastewater treatment process, the difference from Example 1 is that the volume ratio of liquid nitrogen to sewage in this example is 1:40.

Embodiment 3

[0042] Example 3: An industrial wastewater treatment process, the difference from Example 1 is that the volume ratio of liquid nitrogen to sewage in this example is 1:50.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com