Membrane coal gasifier process water resource utilization process

A technology of coal gasification and water resources, applied in the field of water treatment, can solve the problems of insufficient process purification effect, uneven water output, high chemical consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

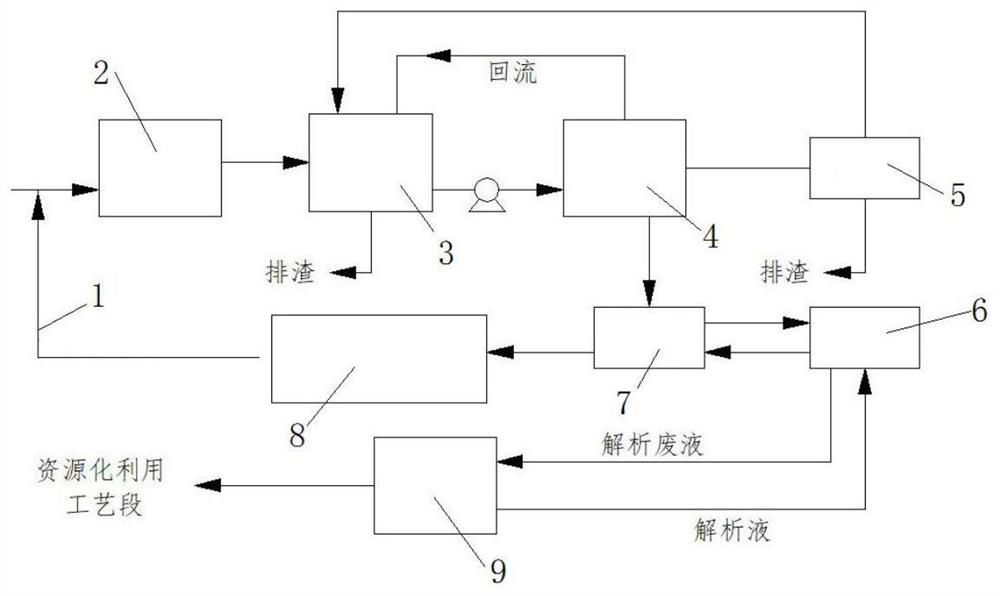

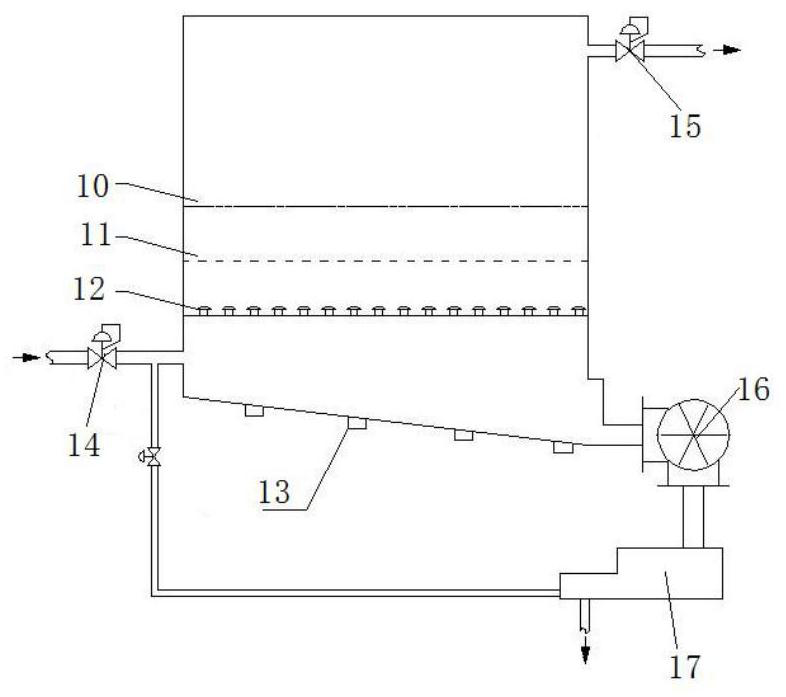

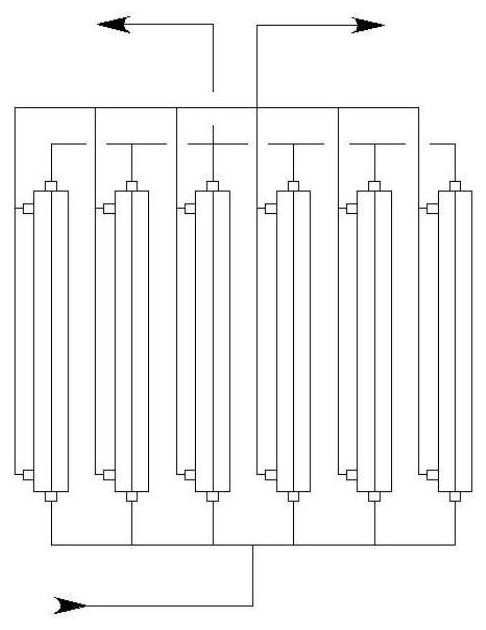

[0029] This embodiment provides a water resource utilization process of a membrane coal gasification furnace process, which is implemented through a flash tank, a buffer settling tank, a membrane device, a softening tank, an analysis device, and a reactor. The buffer settling tank includes a settling tank body, a centrifugal pump and supporting pipeline instrument valves; the membrane device includes a nanoscale inorganic membrane group, a centrifugal pump and supporting pipeline instrument valves; the softening tank includes a softener and supporting pipeline instrument valves; The analysis device includes an analysis liquid pool, an analysis pump, an analysis filter and supporting pipeline instrument valves; the reactor includes a reactor body, a clear liquid pump, a dosing pump, a sludge pump and supporting pipeline instrument valves.

[0030] The process adopts the process of "flash evaporation + module + softening + analysis + recovery" to treat the coal gasification proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com