Positioning and swing eliminating method for under-actuated tower crane with load lifting motion

A tower crane, lifting motion technology, applied in transportation and packaging, load hanging components, safety devices, etc., can solve the problems of external disturbance, dynamic characteristics such as natural frequency, parameter uncertainty, etc., and achieve stable convergence speed. Improve, fast and efficient trajectory tracking positioning and load swing suppression, enhance the effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

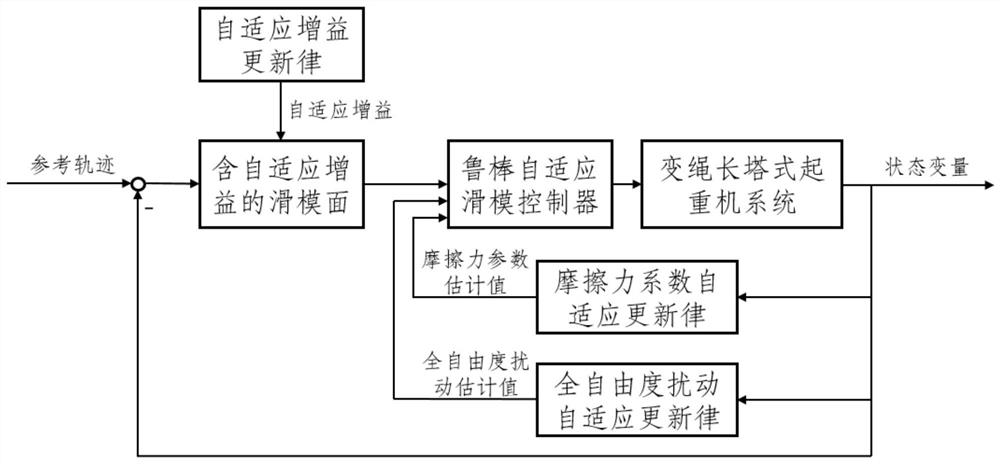

Method used

Image

Examples

Embodiment 1

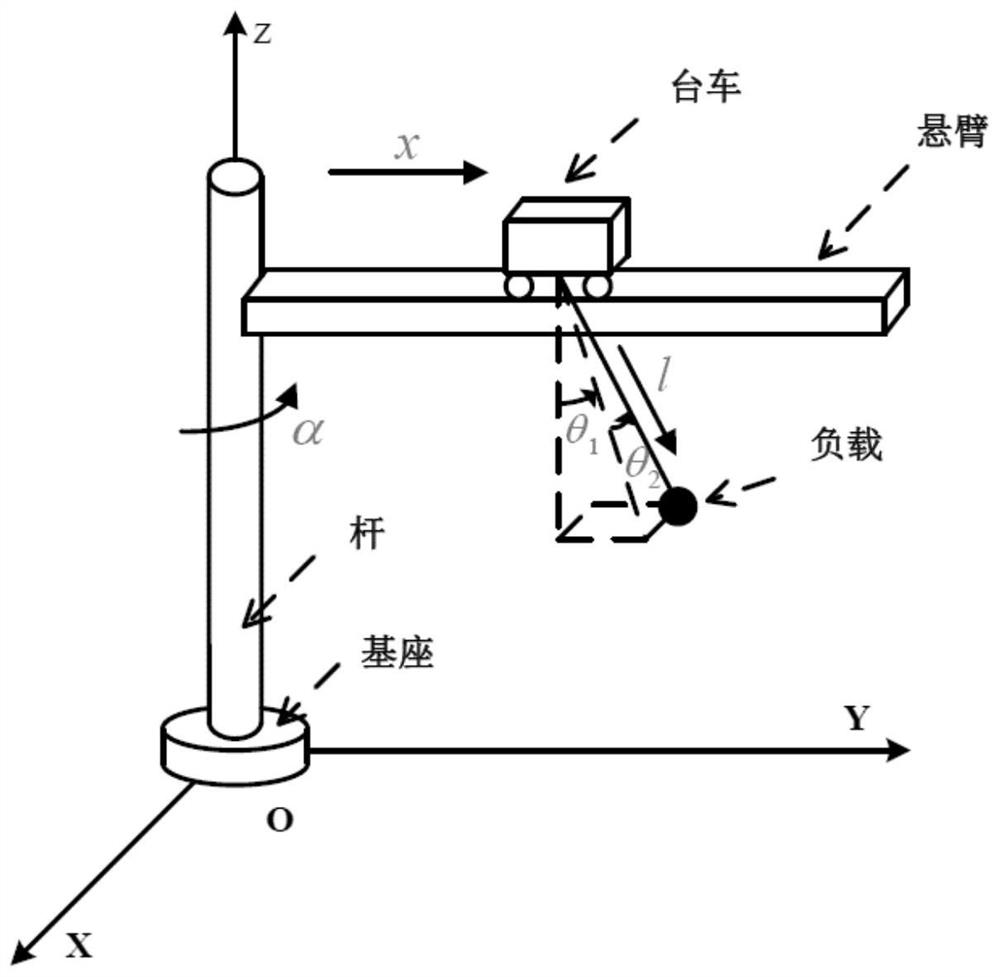

[0062] Traditional underactuated crane positioning and anti-swing control is usually aimed at the bridge crane system. Even if the multi-degree-of-freedom bridge crane moves in three-dimensional space, the dynamic nature of its drive mechanism is still a linear force, and the dynamic characteristics are still simple and easy to control. , but when there are different driving forces in the crane transportation task, such as the control of the tower crane studied in the present invention, one direction is the translational force of the trolley, and the other direction is the torque of the boom; at this time, due to the centrifugal motion The participation of the system makes the dynamic characteristics of the system very complicated. At the same time, when the load is lifted and lowered, the natural frequency of the load swing of the crane system will change. At this time, it is inevitable that the previous design for the ordinary simple pendulum will appear. Controller failure; ...

Embodiment 2

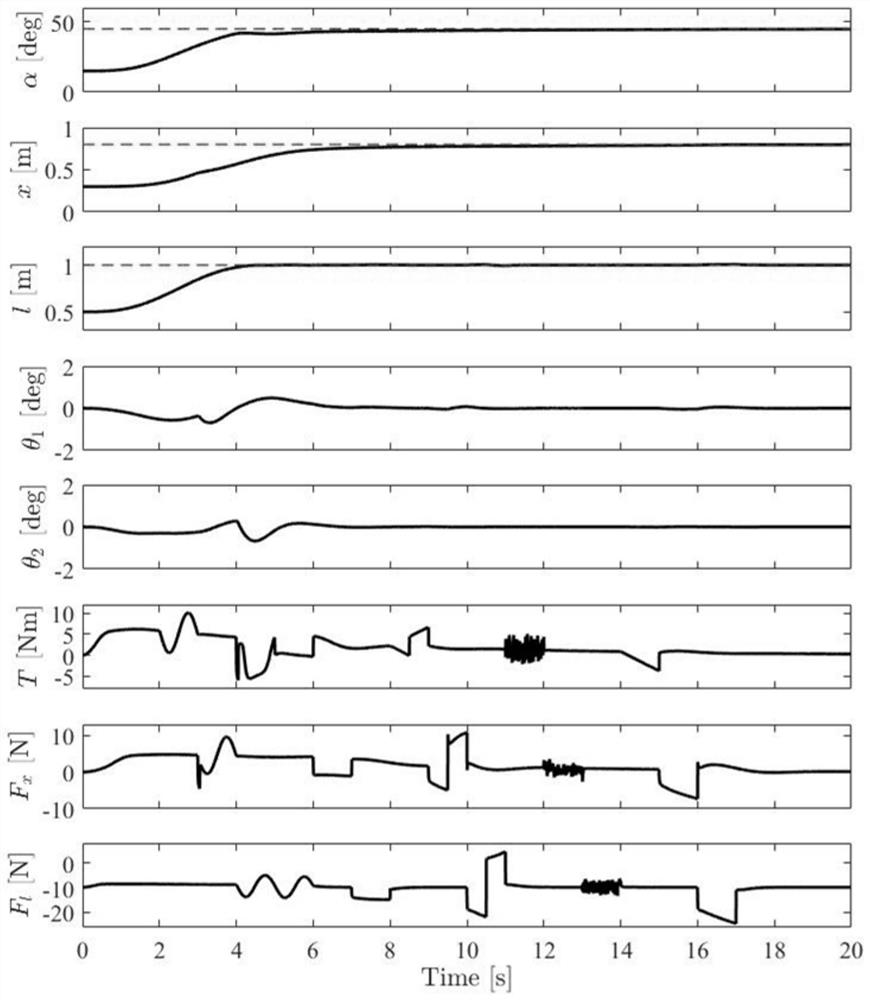

[0134] refer to Figure 3-4 , is the second embodiment of the present invention. In order to better verify and illustrate the technical effects adopted in the method of the present invention, the traditional controller LQR is selected for testing in this embodiment, and the test results are compared with scientific demonstration methods to verify The real effect of this method.

[0135] In order to conduct experiments better, in the simulation environment in MATLAB / Simulink to verify the situation when the device has friction and full-degree-of-freedom integrated interference, the controller LQR and the controller using this control method are selected for experiments, and the controller LQR uses The control method is:

[0136]

[0137]

[0138]

[0139] For the controller of this method, the parameters are selected as:

[0140] k 1 =0.19,k 2 =0.21,k 3 =5.5,k 4 =7.8,k 5 =7.8,

[0141] mu i =280,γ i =80,i=1,...,5

[0142]

[0143]

[0144]

[0145] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com