Slurry flowing forming machine for calcium silicate board production

The technology of calcium silicate board and flow machine is applied in the field of calcium silicate board production, which can solve the problems of easy sticking on flattening rollers, inconvenient spacing of calcium board cutting, and inability to flatten calcium silicate slurry, so as to ensure the surface The effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

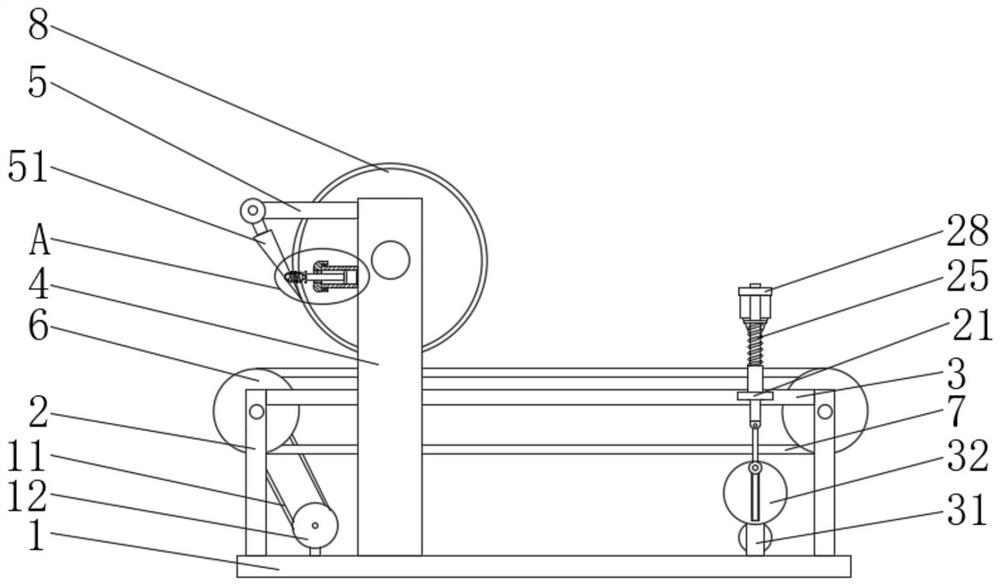

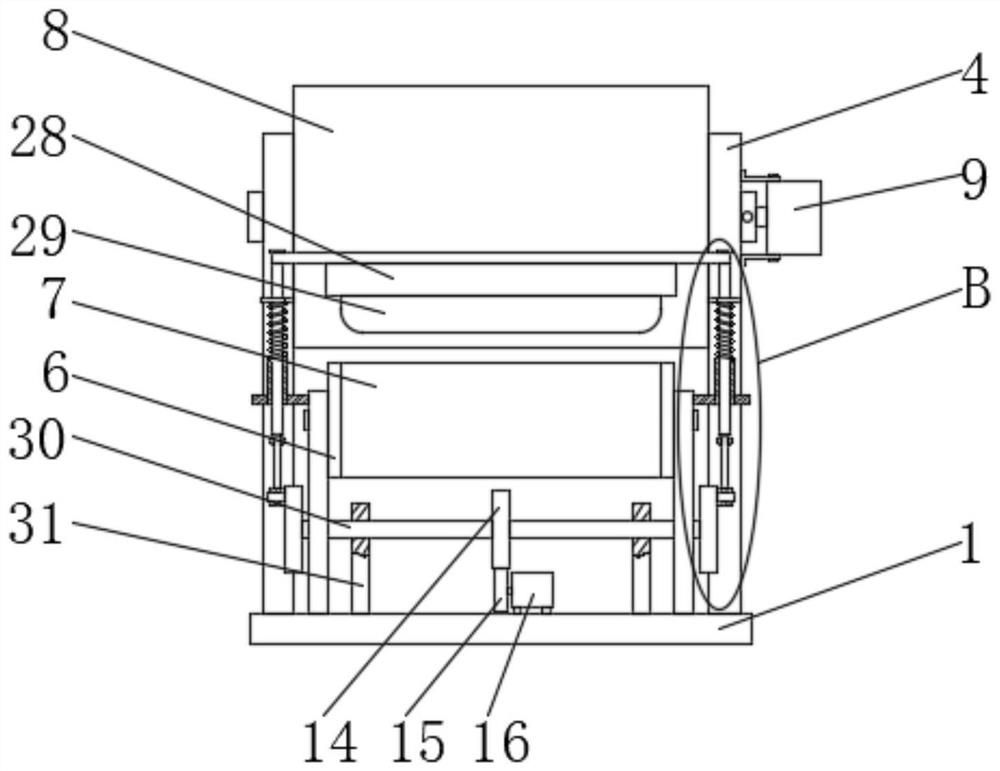

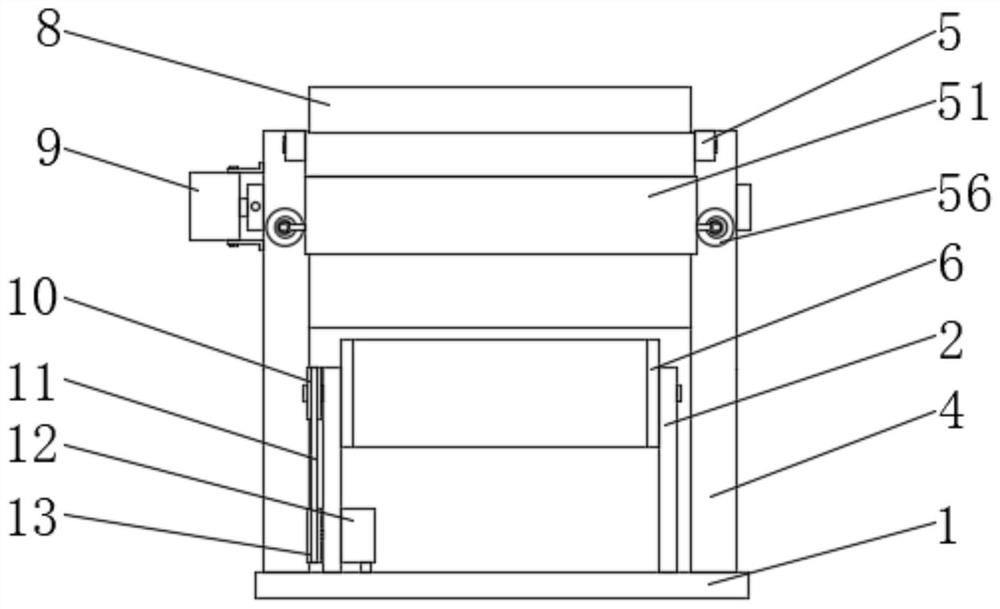

[0027] A flow machine for the production of calcium silicate boards, including a base 1, a support column 2, a cross bar 3, a support frame 4, a hinged rod 5, a driving roller 6, a conveyor belt 7, a flattening roller 8, a reduction motor 9 and Connecting ring 27, the upper end of the base 1 is fixedly connected with four evenly distributed support columns 2, and a cross bar 3 is fixedly connected between every two support columns 2, and the upper end of the base 1 is fixedly connected with two Symmetrically distributed support frame 4, the left end of the support frame 4 is fixedly connected with a hinge rod 5, and a drive roller 6 is rotatably connected between every two support columns 2, and a conveyor belt 7 is sleeved on the outside of the drive roller 6 A flattening roller 8 is rotatably connected between the two support frames 4, and a reduction motor 9 is fixedly connected to the outside of one of the support frames 4, and the output shaft of the reduction motor 9 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com