Centrifugal machine with anti-shake guiding function

A centrifuge and functional technology, applied in the field of centrifuges, can solve the problems of large jitter, inability to remove impurities synchronously, incomplete separation and purification, etc., and achieve the effects of reducing jitter, improving the effect of slag aggregation, and completely separating and purifying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

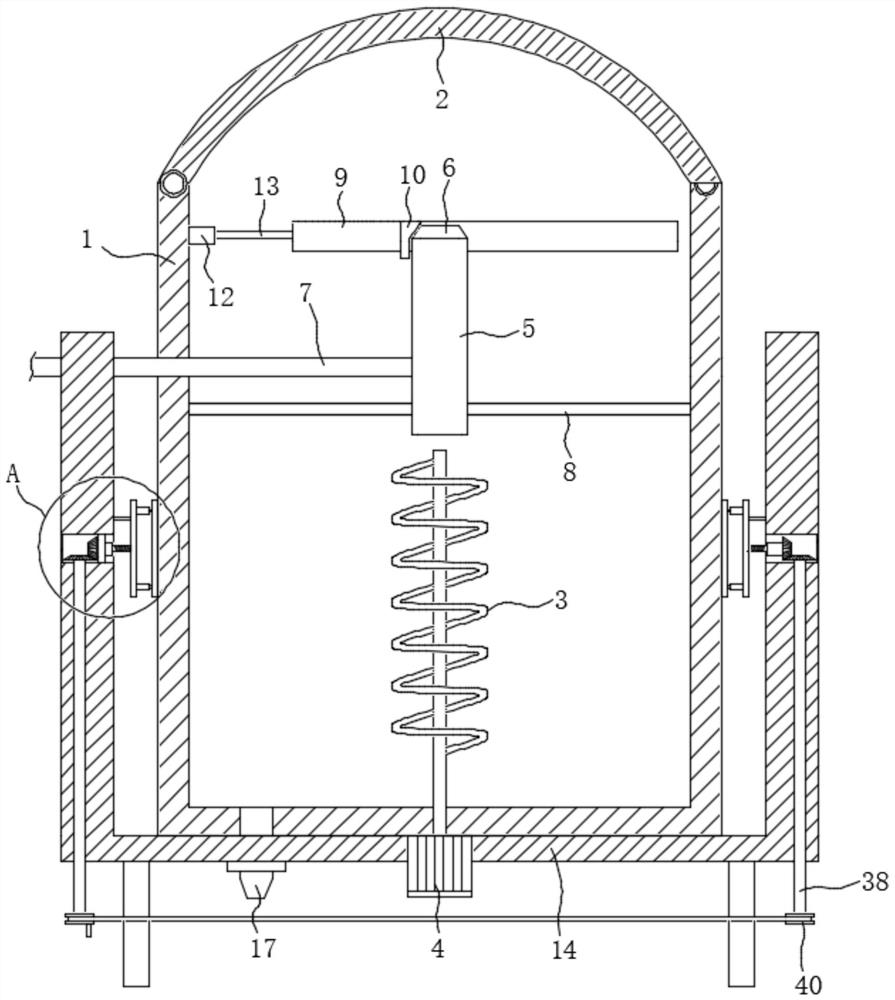

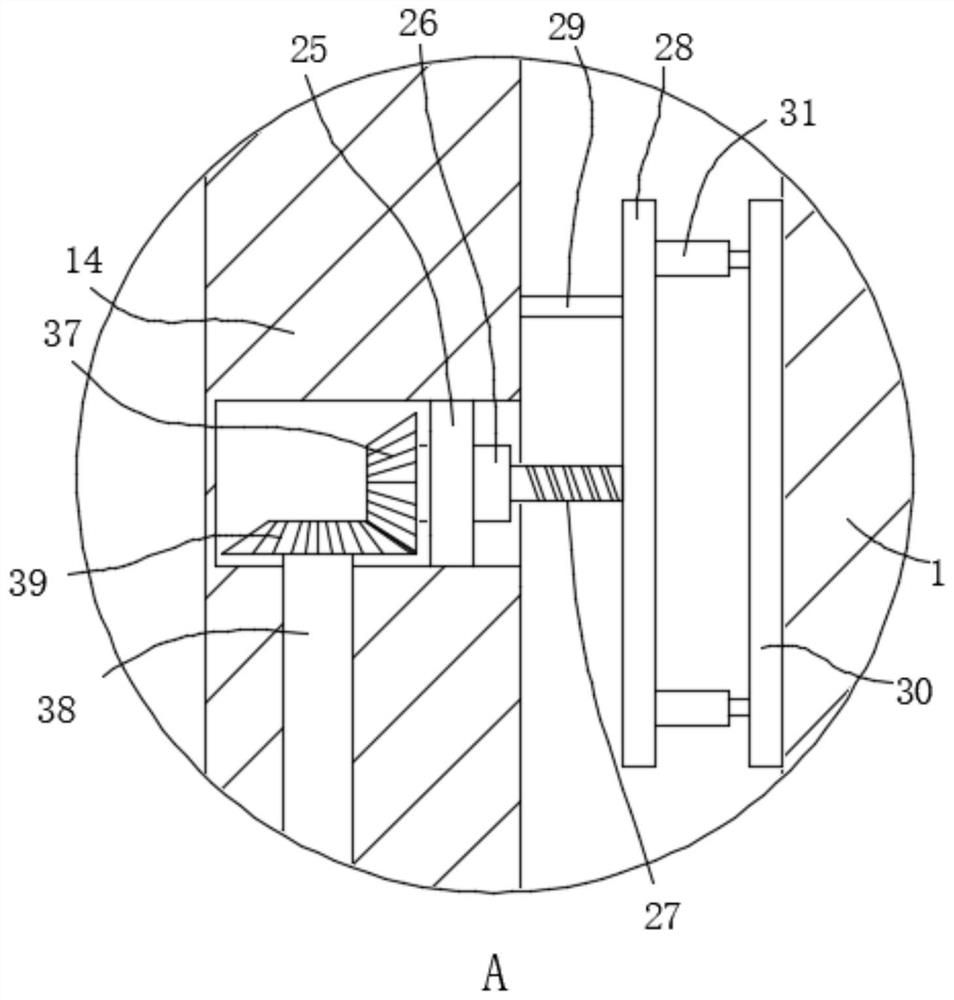

[0032] Please combine Figure 1 to Figure 6 , the centrifuge with anti-vibration guiding function includes an inner cylinder 1 and an outer cylinder 14 sleeved outside the inner cylinder 1 . In this embodiment, the top of the inner cylinder 1 is installed with a cylinder cover 2 matching it. The cylinder cover 2 is fixedly connected with the inner cylinder 1 to facilitate the opening or closing of the cylinder lid 2 on the inner cylinder 1 . The bottom of the outer cylinder 14 is provided with a drain valve 17 connected to the inside of the inner cylinder 1 , through which the centrifuged liquid in the inner cylinder 1 can be sequentially released. Support feet (not shown) are installed on the bottom of the outer cylinder 14, and are supported on the ground by the support frame.

[0033] The inner cylinder 1 is provided with a spiral stirring shaft 3, the stirring shaft 3 is an ascending spiral structure, and a motor 4 is installed at the bottom of the outer cylinder 14, and...

Embodiment 2

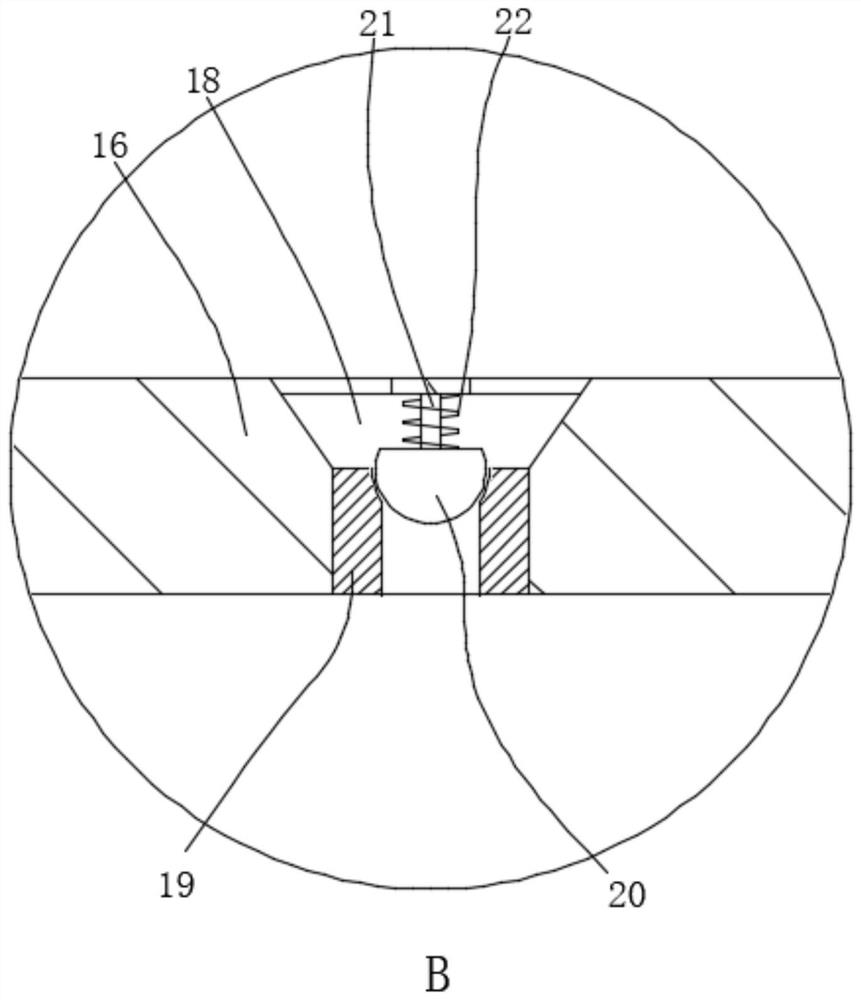

[0048] Please combine Figure 7 , this embodiment 2 is an improved solution of embodiment 1, specifically, the bottom of the inner cylinder 1 is provided with an overflow cover 16, and an air flow space is formed between the inner cylinder 1 and the overflow cover 16. A plurality of air outlet holes 18 with inverted trapezoidal cross-sections are opened on the top of the flow cover 16 . A valve seat 19 is arranged in the outlet hole 18 , and a valve ball 20 matched with the valve seat 19 is arranged in the outlet hole 18 above the valve seat 19 . The side of the valve ball 20 away from the valve seat 19 is connected to the cover body of the flow cover 16 through the telescopic rod one 21 . A spring 22 is sheathed on the outside of the telescopic rod 1 21 . An air pump 15 is installed on the bottom of the outer cylinder 14, and the air outlet end of the air pump 15 communicates with the airflow space through a conduit.

[0049] An inert gas that does not react with the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com