Hair cutting rolling brush, sweeping robot and dust collector

A vacuum cleaner and hair cutting technology, which is applied to vacuum cleaners, manual sweeping machines, carpet cleaning, etc., can solve the problems of affecting the life of the roller brush and reducing the working efficiency of the roller brush, and achieve the effect of improving the cleaning ability and reducing the degree of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

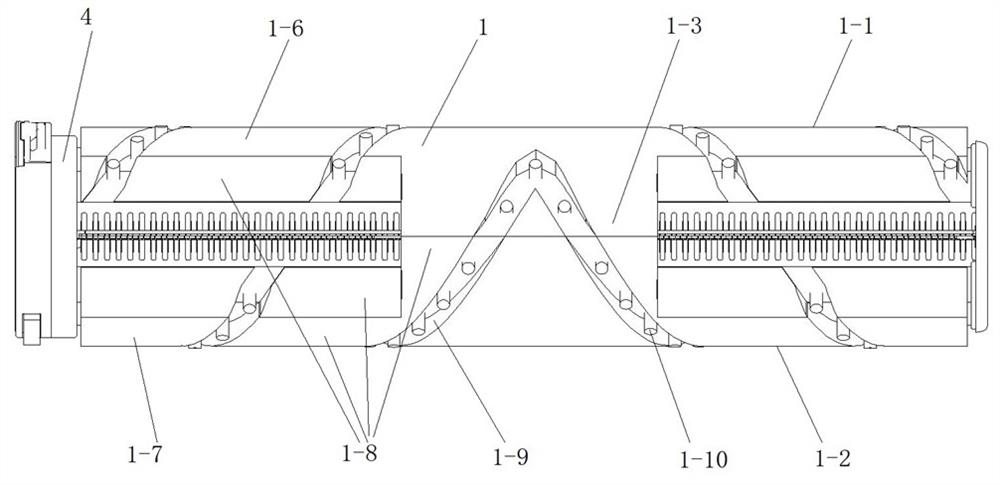

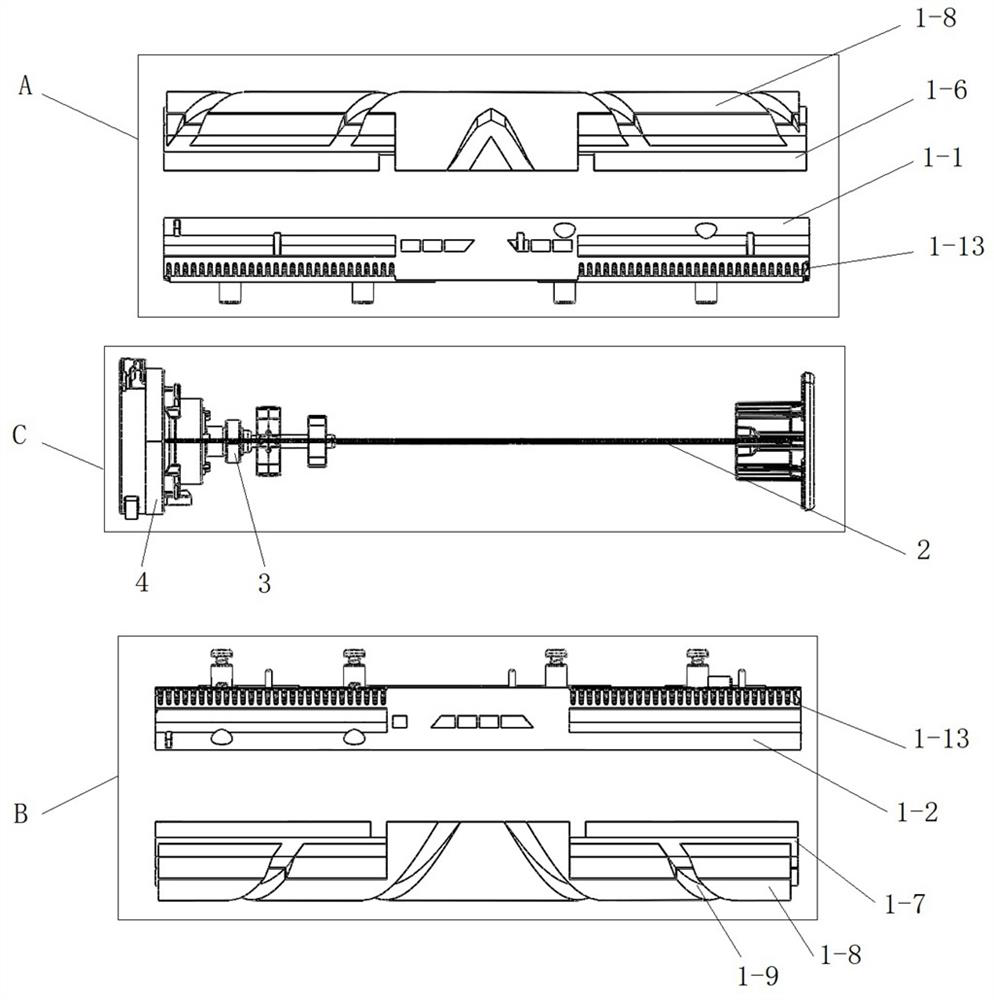

[0035] like Figure 1 to Figure 4 As shown in the figure, the hair-cutting roller brush of the present invention includes a roller brush body 1 and two sets of hair-cutting blades 2. The roller brush body 1 is composed of a first roller sheet 1-1 and a second roller sheet 1-2 facing each other. The groups of hair cutting blades 2 are respectively installed at the two joints of the first roller sheet 1-1 and the second roller sheet 1-2, and each group of hair cutting blades 2 is stacked on top of each other by a static blade 2-4 and a movable blade 2-5 Put the installation composition. The outer surface of the first roller sheet 1-1 is provided with a first cleaning portion 1-6, the outer surface of the second roller sheet 1-2 is provided with a second cleaning portion 1-7, the first cleaning portion 1-6 and The second cleaning parts 1-7 are all used to roll up dust and other garbage on the surface to be cleaned so that they are sucked into the vacuum cleaner. The roller brus...

Embodiment 2

[0042] The difference between the hair cutting roller brush in this embodiment and embodiment 1 is that the first partition 1-3, the second partition 1-4 and the third partition 1-5 are not cleaned by the first cleaning part 1-6. Or the second cleaning part 1-7 is covered, and other cleaning parts are not provided. The first partition part 1-3, the second partition part 1-4 and the third partition part 1-5 are made of flexible materials. The first cleaning part 1 -6. The second cleaning part 1-7, the first partition part 1-3, the second partition part 1-4 and the third partition part 1-5 are all located on the same circumferential surface concentric with the roller brush body. In this way, when the roller brush body is rotated to the installation position of the side trimming blade, the part in contact with the ground is a ring layer of the same size, and the roller brush will not vibrate.

Embodiment 3

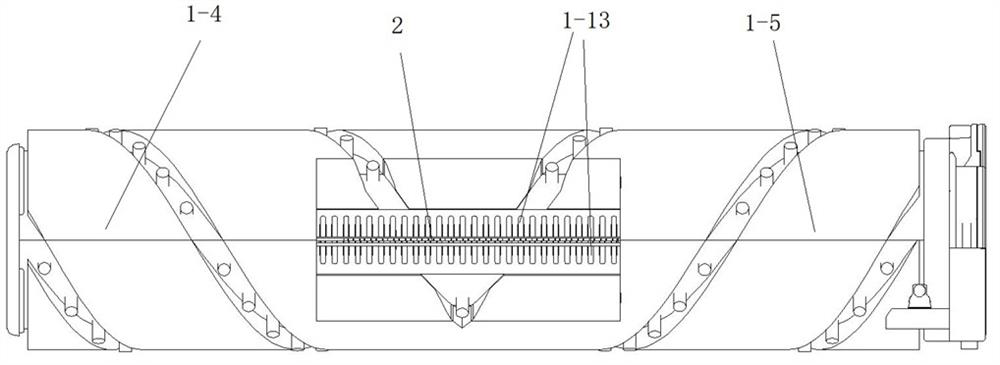

[0044] The difference between the hair-cutting roller brush in this embodiment and Embodiment 1 is that the hair-cutting blade is installed in sections at the two joints of the first roller sheet 1-1 and the second roller sheet 1-2, and the partition is provided Between the two groups of hair-cutting blades and without covering the hair-cutting blades, a group of blade drivers are respectively arranged at both ends of the roller brush body 1, and the hair-cutting blades at the two ends of the partition are respectively driven by the blade drivers on the corresponding side to rotate. For reciprocating motion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com