Air tightness detection machine for vacuum pump assembly line

An assembly line, air tightness technology, applied in the liquid/vacuum degree of liquid tightness measurement, by measuring the fluid's acceleration and deceleration rate, etc., can solve the insertion angle sealing valve scratch, monitor shaft movement, air tightness impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

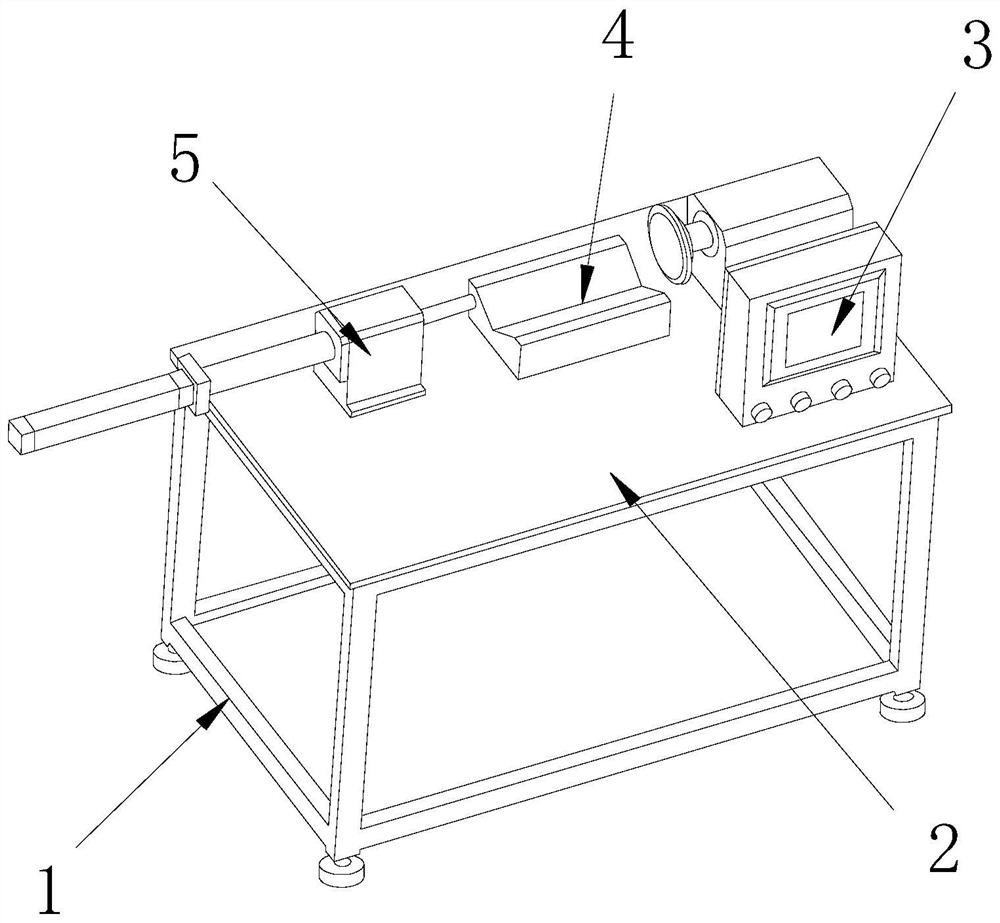

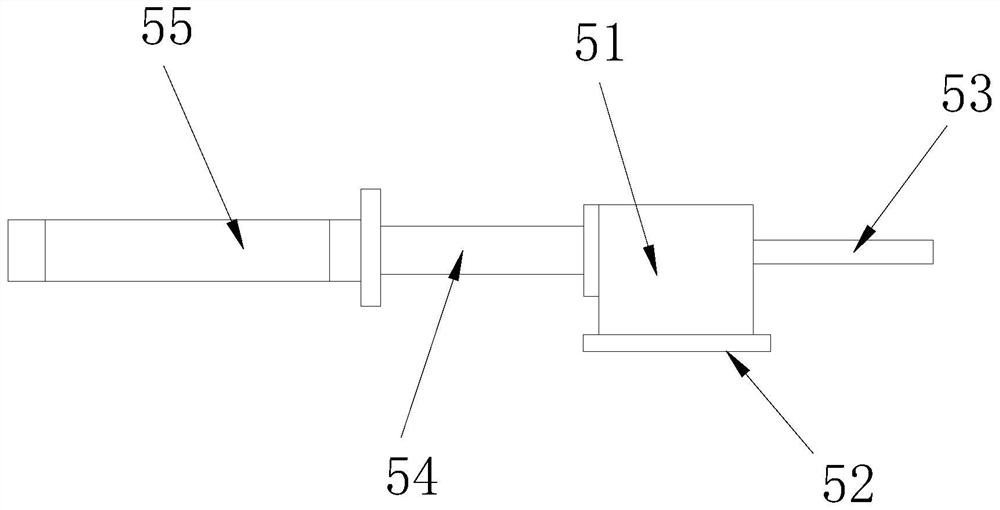

[0024] see Figure 1-Figure 3 , the specific embodiment of the present invention is as follows: a kind of air tightness detection machine that is used for vacuum pump assembly line, its structure comprises base 1, operating table 2, console 3, fixed base 4, tester 5, and the top surface of described base 1 It is welded and connected with the bottom surface of the console 2, the bottom surface of the console 3 is fixedly installed on the top surface of the console 2, the bottom surface of the fixing base 4 is welded to the top surface of the console 2, and the bottom surface of the tester 5 is fixedly installed on the top surface of the console 2 Surface; the testing machine 5 includes a rotary machine 51, a welding table 52, a test head 53, a data stick 54, and an air pressure head 55. Fixedly installed inside the rotary machine 51, the left side of the rotary machine 51 is connected to the left side of the air pressure head 55 through the data stick 54, and the top surface of...

Embodiment 2

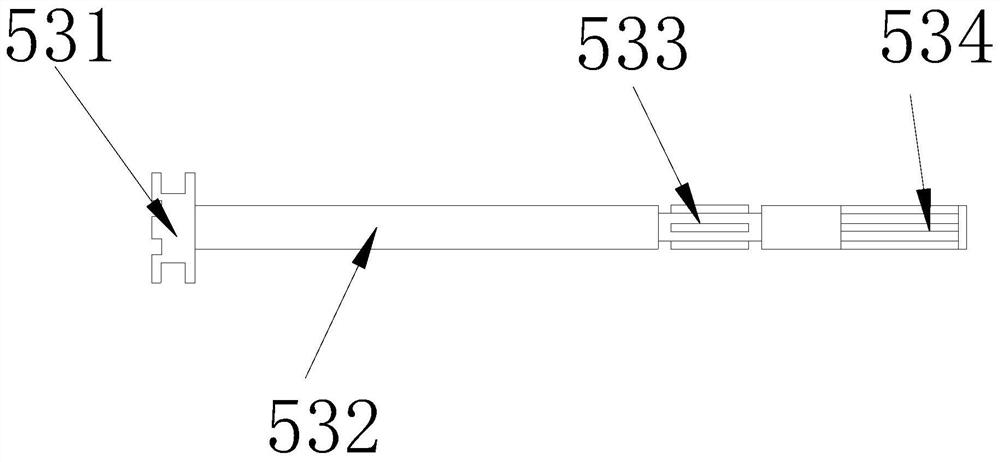

[0028] see Figure 4-Figure 7 The specific embodiment of the present invention is as follows: the grinding shaft 533 includes an inner shaft A1, a pulling rod A2, an elastic shell A3, a plug A4, and a wiper A5, and the outer layer of the inner shaft A1 is in contact with the bottom of the pulling rod A2. The bottom of the plug A4 is fixedly installed on the outer ring of the inner shaft A1. The wiper A5 is embedded in the elastic shell A3. There are four blocks A5, and the four wiper blocks A5 are evenly embedded in the elastic shell A3, which is beneficial to increase the friction frequency.

[0029] Wherein, the wiper block A5 includes a contact handle A51, a support platform A52, a grinding plate A53, a chip groove A54, and a grinding block A55. The top of the contact handle A51 is movably engaged with the bottom of the support platform A52, and the bottom surface of the grinding plate A53 is fixed Installed on the top surface of the support platform A52, the chip flute A5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com