Rapid photo-thermal response shape memory driver as well as preparation method and application thereof

A photothermal response and driver technology, applied in textiles and papermaking, fiber processing, fiber types, etc., can solve the problems of high market price and unfavorable industrial promotion and use, and achieve excellent mechanical properties, enhanced mechanical properties, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of MC-1 composite film

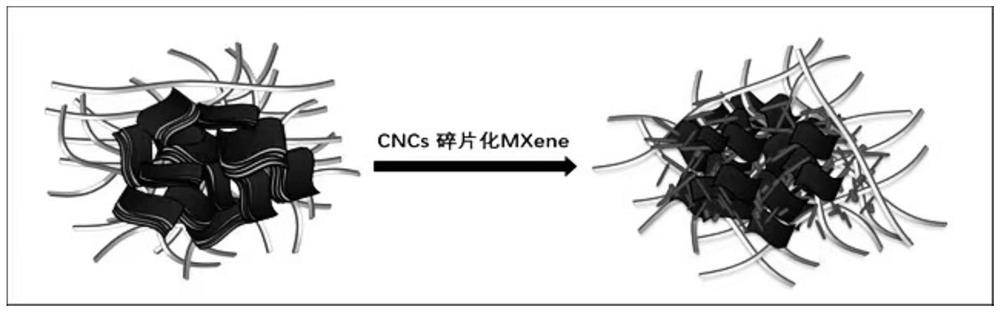

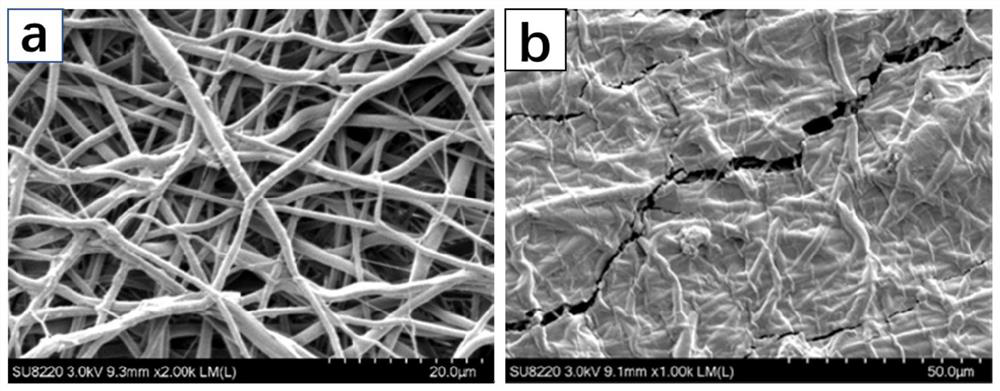

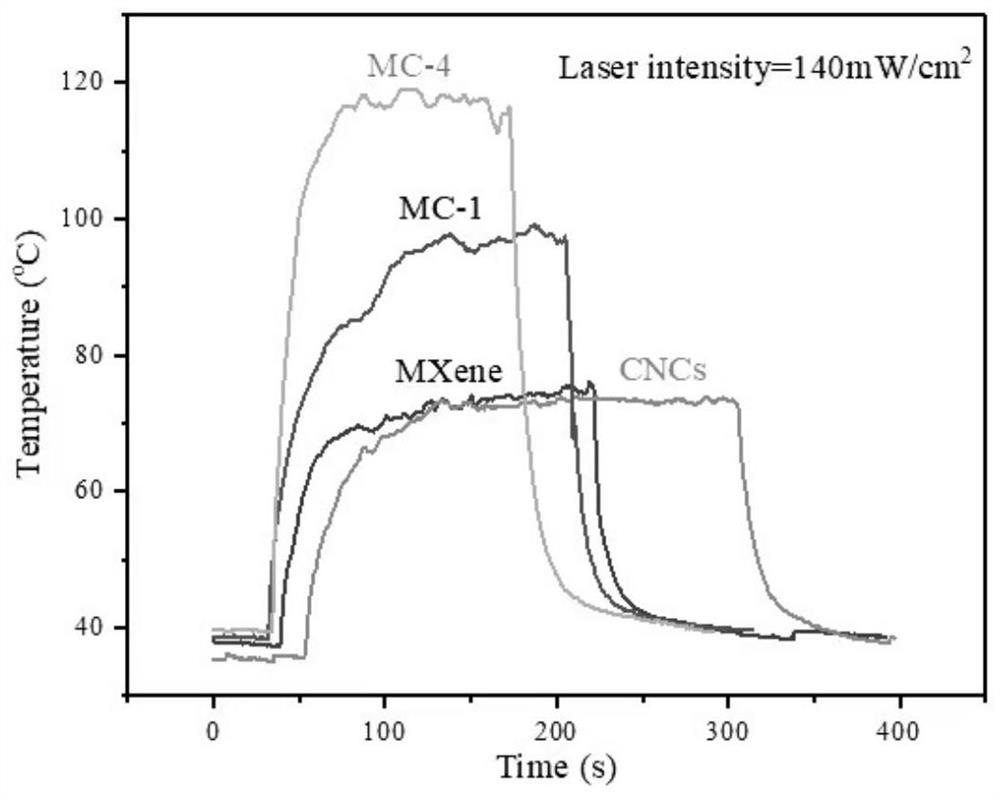

[0043] The Tg-SMPU electrospun membrane was cut into a size of 40mm×40mm, heated and stretched, and the pre-stretched ratio was 20%. Take 0.8mL of MXene aqueous solution with a concentration of 5mg / mL and 0.4ml of an aqueous solution of CNCs with a concentration of 10mg / mL in a centrifuge tube, mix them, and sonicate to obtain a mixed aqueous solution of MXene / CNCs, which is evenly drip-coated on the electrospun membrane. The MC-1 composite film can be obtained by drying with an infrared lamp, and the film thickness is about 100 μm. Such as figure 1 It is shown that after mixing CNC with high rigidity and MXene, the original large sheets of MXene will be fragmented, which will facilitate multiple reflections of light between sheets to improve the light-to-heat conversion efficiency. The morphology of the MC-1 composite film was characterized by scanning electron microscopy, as shown in figure 2 As shown, MXene and CNCs deposi...

Embodiment 2

[0051] (1) Preparation of MC-2 composite membrane

[0052] The Tg-SMPU electrospun membrane was cut into a size of 40mm×40mm, heated and stretched, and the pre-stretched ratio was 20%. Take 0.8mL of MXene aqueous solution with a concentration of 5mg / mL and 0.8ml of an aqueous solution of CNCs with a concentration of 10mg / mL in a centrifuge tube, mix them, and sonicate to obtain a mixed aqueous solution of MXene / CNCs, which is evenly drip-coated on the electrospun membrane. The MC-2 composite film can be obtained by drying with an infrared lamp, and the film thickness is about 100 μm.

[0053] (2) Photothermal test

[0054] Cut the MC-2 composite film into a size of 10mm×10mm, adjust the intensity of the infrared laser, and make the spot irradiate the surface of the sample, and record the surface temperature of the sample with a thermal imager. Observe its temperature change, when its temperature reaches the saturation temperature and remains stable, turn off the laser power....

Embodiment 3

[0056] (1) Preparation of MC-3 composite membrane

[0057] The Tg-SMPU electrospun membrane was cut into a size of 40mm×40mm, heated and stretched, and the pre-stretched ratio was 20%. Take 0.8mL of MXene aqueous solution with a concentration of 5mg / mL and 1.2ml of an aqueous solution of CNCs with a concentration of 10mg / mL in a centrifuge tube, mix them, and sonicate to obtain a mixed aqueous solution of MXene / CNCs, which is evenly drip-coated on the electrospun membrane. The MC-3 composite film can be obtained by drying with an infrared lamp, and the film thickness is about 100 μm.

[0058] (2) Photothermal test

[0059] Cut the MC-3 composite film into a size of 10mm×10mm, adjust the intensity of the infrared laser, and make the spot irradiate the surface of the sample, and record the surface temperature of the sample with a thermal imager. Observe its temperature change, when its temperature reaches the saturation temperature and remains stable, turn off the laser power....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com