A kind of preparation method of carbon black

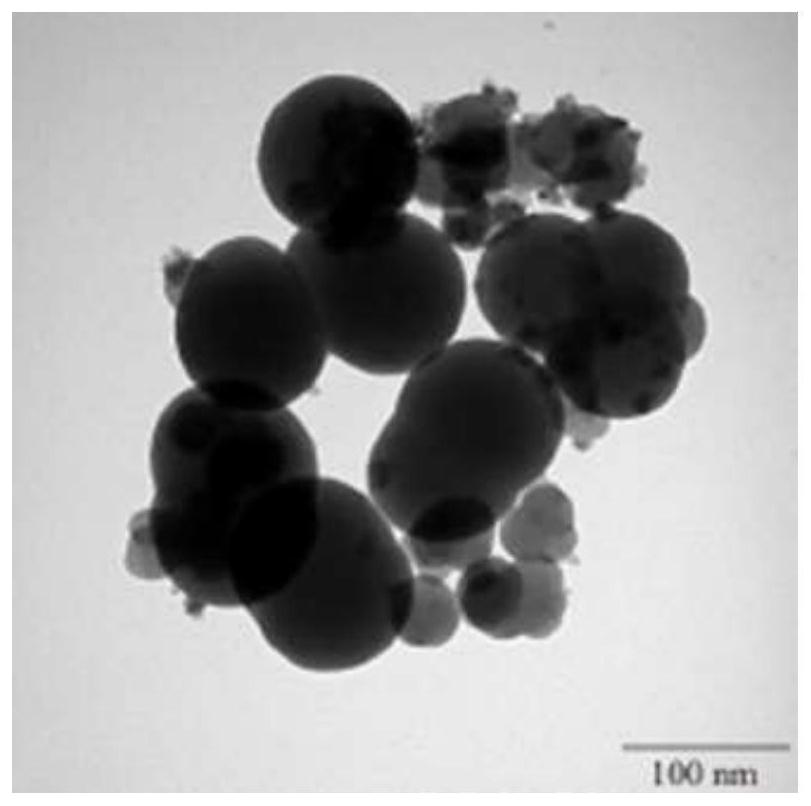

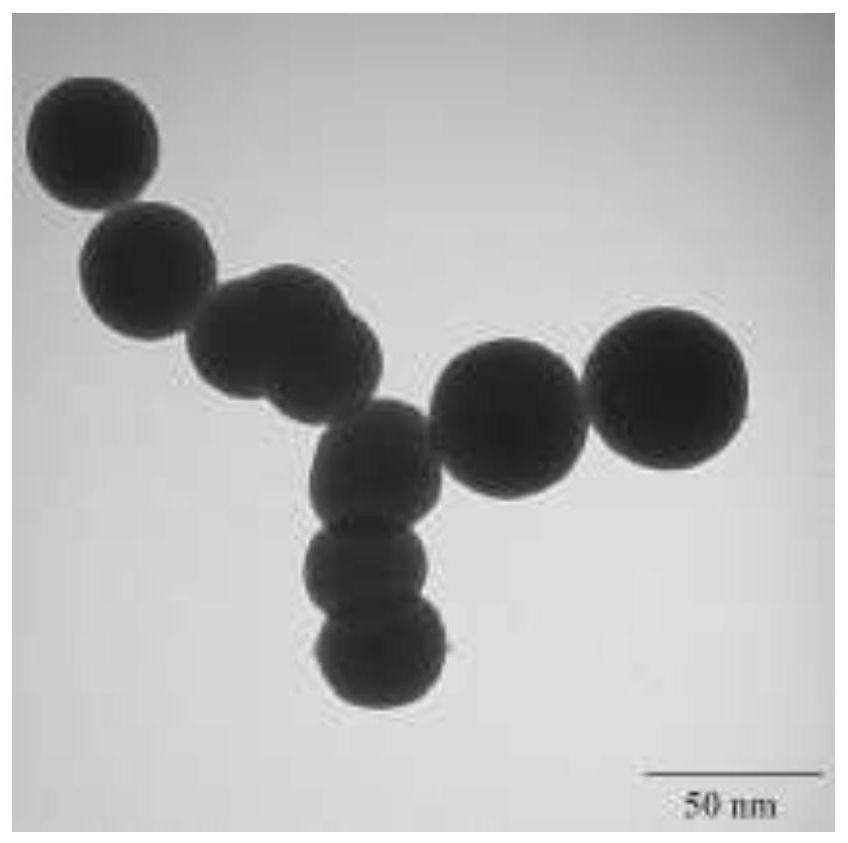

A technology of carbon black and structural inhibitors, applied in the direction of fibrous fillers, etc., can solve the problems of easy aggregation of carbon black into blocks, low energy utilization rate, large particles, etc., to achieve reduced energy consumption, difficult aggregation, and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The tar containing methyl carbonate and hydroquinone was prepared, wherein the content of methyl carbonate was 1.7% (volume fraction) and the content of hydroquinone was 3‰ (volume fraction). The configured tar is sprayed with a high-pressure jet device in the opposite direction. After the spray, a turbulent fluid system is formed to form nano-atomized droplets, which are sent to the combustion chamber together with the preheated hot air to burn, and the two pairs are controlled. The distance of the tar nozzle is 1mm, and the injection pressure is 1MPa. After the combustion reaction is completed, it is sent to the reaction chamber, and is pyrolyzed to form carbon black at 1700°C, and the generated carbon black is cooled with quench water with a conductivity of 1us / cm. The cooled flue gas enters the bag filter for collection, and after granulation and drying, the finished carbon black is finally obtained.

Embodiment 2

[0030] A tar containing ethyl acetate and hydroquinone was prepared, wherein the ethyl acetate content was 2.6% (volume fraction) and the hydroquinone content was 18‰ (volume fraction). The configured tar is sprayed with a high-pressure jet device in the opposite direction. After the spray, a turbulent fluid system is formed to form nano-atomized droplets, which are sent to the combustion chamber together with the preheated hot air to burn, and the two pairs are controlled. The distance of the tar nozzle is 2mm, and the injection pressure is 2MPa. After the combustion reaction is completed, it is sent to the reaction chamber, and is pyrolyzed to form carbon black at 1600 °C, and the generated carbon black is cooled with quench water with a conductivity of 2us / cm. The cooled flue gas enters the bag filter for collection, and after granulation and drying, the finished carbon black is finally obtained.

Embodiment 3

[0032] The tar containing ethyl carbonate and dopamine is prepared, wherein the content of ethyl carbonate is 2.1% (volume fraction) and the content of dopamine is 13‰ (volume fraction). The configured tar is sprayed with a high-pressure jet device in the opposite direction. After the spray, a turbulent fluid system is formed to form nano-atomized droplets, which are sent to the combustion chamber together with the preheated hot air to burn, and the two pairs are controlled. The distance of the tar nozzle is 2mm, and the injection pressure is 3MPa. After the combustion reaction is completed, it is sent to the reaction chamber, where it is pyrolyzed to form carbon black at 1600°C, and the resulting carbon black is cooled with quench water with a conductivity of 6us / cm. The cooled flue gas enters the bag filter for collection, and after granulation and drying, the finished carbon black is finally obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com