Single-power-source multi-stage telescopic mechanism and transportation equipment

A single power source, transportation equipment technology, applied in mechanical conveyors, transportation and packaging, conveyors, etc., can solve unfavorable sampling inspection and production status observation and abnormal handling, can not achieve full automation of workpiece transportation, occupy a large area of space, etc. problems, to achieve the effect of good equipment synchronization, easy maintenance and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

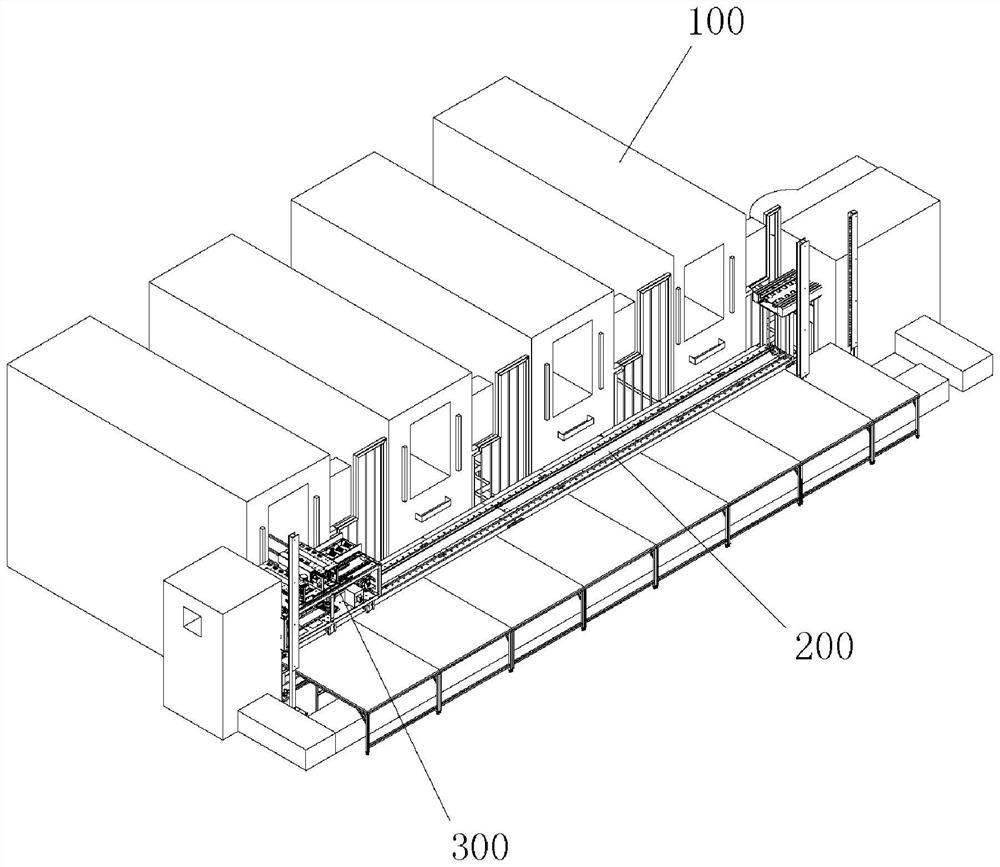

[0040] This embodiment provides a transport device, such as figure 1 -As shown in -6, it includes multiple machining centers 100, rails 200 and transfer vehicles 300;

[0041] The plurality of machining centers 100 are arranged linearly, and the track 200 is located on one side of the plurality of machining centers 100 along the lateral direction. The transfer vehicle 300 can walk on the track 200 and pass through the plurality of machining centers 100 for picking and placing workpieces.

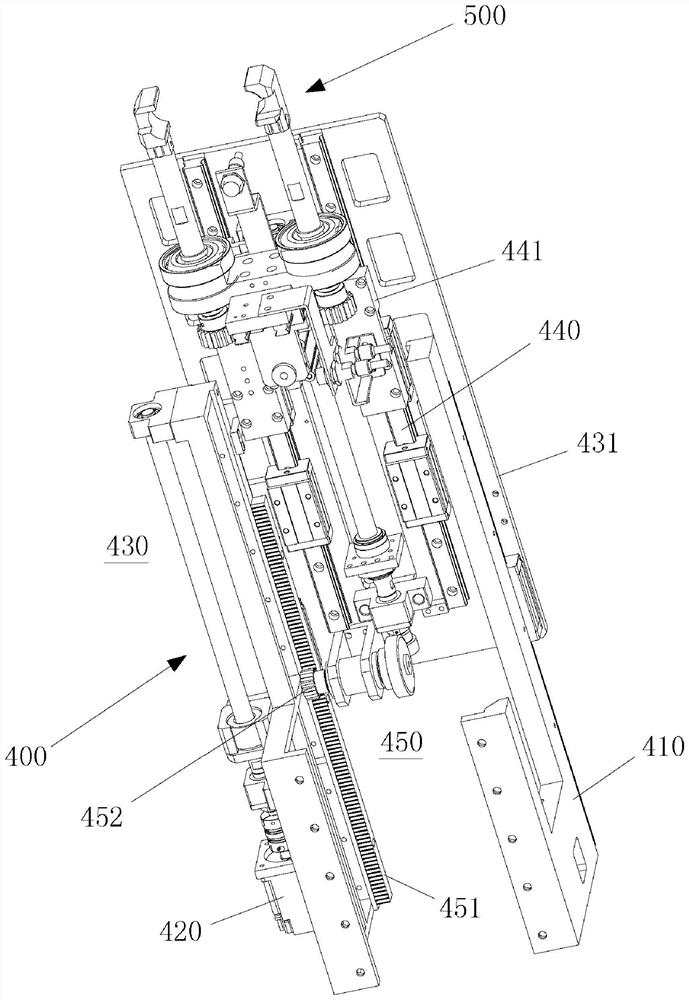

[0042] The transfer vehicle 300 in this embodiment is provided with two telescopic mechanisms 400, two clamping mechanisms 500 and a raceway 600, to respectively carry out the removal of the workpiece processed by the designated machining center 100 and the workpiece that needs to be transported to the machining center 100. Placement of workpieces such as figure 1 -2, that is, the processed workpiece in the machining center 100 is clamped by one of the clamping mechanisms 500, and the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com