Automatic feeding machine suitable for flat cable machining and application method of automatic feeding machine

An automatic feeding and feeding technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as difficulty in guaranteeing, difficult to control reclaiming, raw materials and finished products occupying working space and product quality, etc., to improve cleaning, Ensure product quality and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

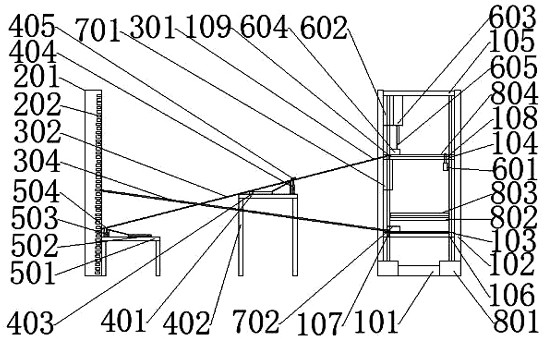

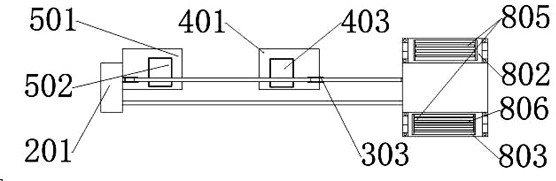

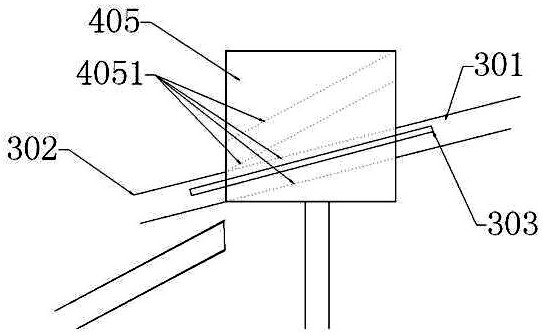

[0051]Example 1, referring to attachmentFigure 1-5An automatic feeder suitable for wire processing, including body frames, feed portions, cyclic hub portions, and intelligent control portions.

[0052]The body frame includes a hub frame and auxiliary frame 201.

[0053]The hub frame includes a base 101, a strut 102, a panel one 103, a panel two 104, and a top plate 105.

[0054]The base 101 is a long cube hollow container 1, the hollow container four angle each provided a strut 102, a panel 103, a panel two 104, and a top plate 105, a panel one 103 and a panel, two 104 square angles, and a panel one 103 and panel two 104. The square opening groove and the strut 102 are adapted, and the panel one 103 is provided on one side of the rectangular through hole 107, "L" shaped via hole 107, and "L" shaped pass hole 107 is located on one side of the rectangular via 106; panel The second 104 is provided with a rectangular through hole II 108, and a rectangular opening groove 109 is provided on the le...

Embodiment 2

[0105]Example 2, on the basis of Example 1, the number of screw motor 801 macr and the carrier 802 layer were increased, and the operational efficiency was increased.

Embodiment 3

[0106]Example 3, on the basis of Example 1, the push rod motor seven and the shutter were added to the bottom surface of the panel 2 104, and the replacement of the shutter three 702 was replaced with the ordinary gate plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com