Coal mine underground autonomous mobile platform and method capable of realizing remote interaction

A technology of autonomous movement and remote interaction, applied to motor vehicles, program control, instruments, etc., can solve the problems of many construction workers, strong electromagnetic interference, and low threshold of disaster-induced disasters, and achieve high operating efficiency, short auxiliary time, and adaptability to construction The effect of a wide range of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

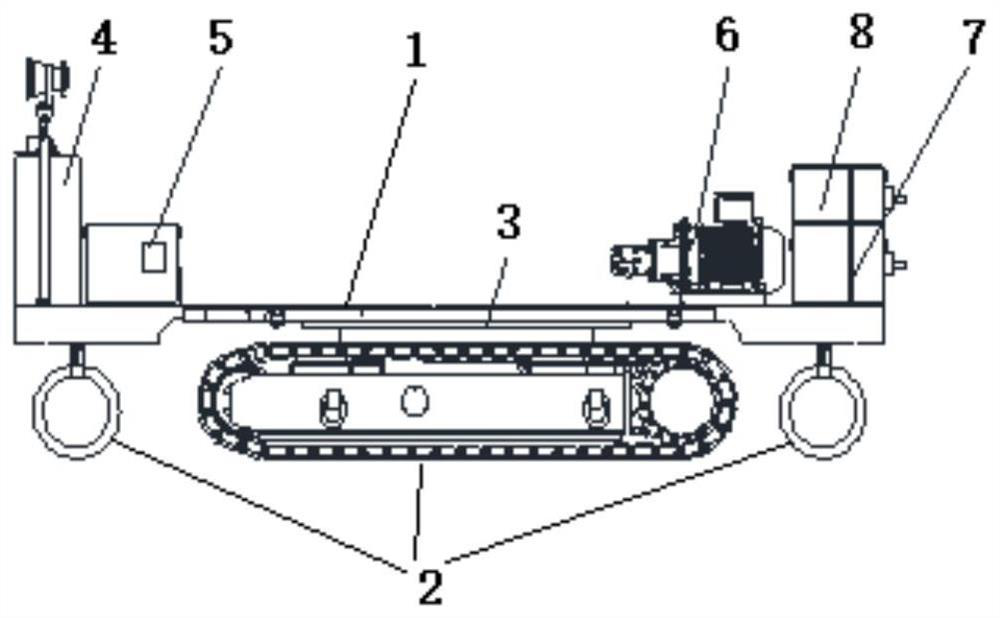

[0044] This embodiment provides a coal mine underground autonomous mobile platform that can realize remote interaction, such as figure 1 As shown, including a vehicle body platform 1, a traveling drive device 2 is provided under the vehicle body platform 1, and a slewing support 3 is provided between the vehicle body platform 1 and the traveling drive device 2 to realize a 360° rotation of the vehicle body platform. The platform 1 is provided with a detection device 4 located at the front of the vehicle body platform 1 , an intelligent control system 5 , a transmission device 6 located at the rear of the vehicle body platform 1 , and a main power box 7 and an auxiliary power box 8 . The space in the middle of the car body platform 1 can be designed according to the type of equipment and materials to be transported and the way of connection.

[0045] The detection device 4 is used to accurately and quickly obtain roadway environmental information, such as Figure 5 shown, incl...

Embodiment 2

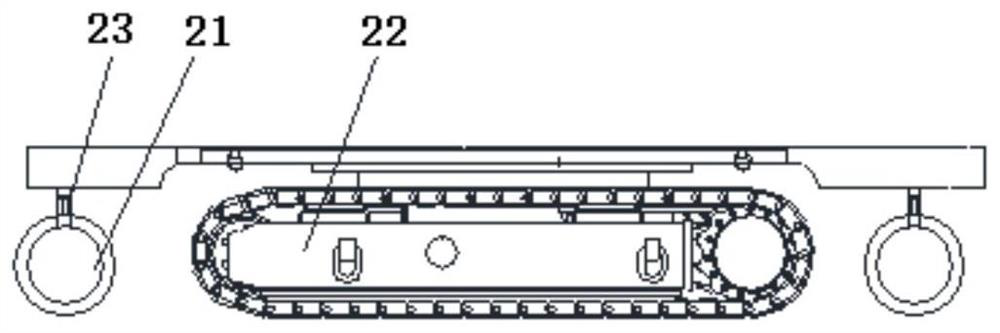

[0073] This embodiment provides a method for moving an autonomous mobile platform in a coal mine that can realize remote interaction. When the autonomous mobile platform is running in a coal mine roadway, the detection device obtains multi-source information data of the coal mine roadway environment image, obstacle information, and platform operating parameters. , and pass it to the intelligent control system, the intelligent control system calculates and analyzes according to the obtained information, independently decides to select the appropriate operation mode and optimize the working path, or the operator performs remote interactive control, and the precise position, operation mode and The optimized path is transmitted to the walking drive device; according to the conditions of the coal mine roadway, the walking drive device is divided into two operating modes: wheel drive and crawler drive.

[0074] When the autonomous mobile platform is transferred and transported in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com