A rapid prototyping device and working method for polytetrafluoroethylene sheet

A technology of polytetrafluoroethylene and forming device, applied in the field of rapid forming device for polytetrafluoroethylene sheet, can solve the problems of sheet surface blowing deformation, unevenness, affecting the overall quality, etc., and achieve accelerated cooling, fast forming, and improved processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

[0047] Among them, the accompanying drawings are only used for exemplary description, and they are only schematic diagrams, not physical drawings, and should not be construed as restrictions on this patent; in order to better illustrate the embodiments of the present invention, some parts of the accompanying drawings will be omitted, Enlarged or reduced, does not represent actual product size.

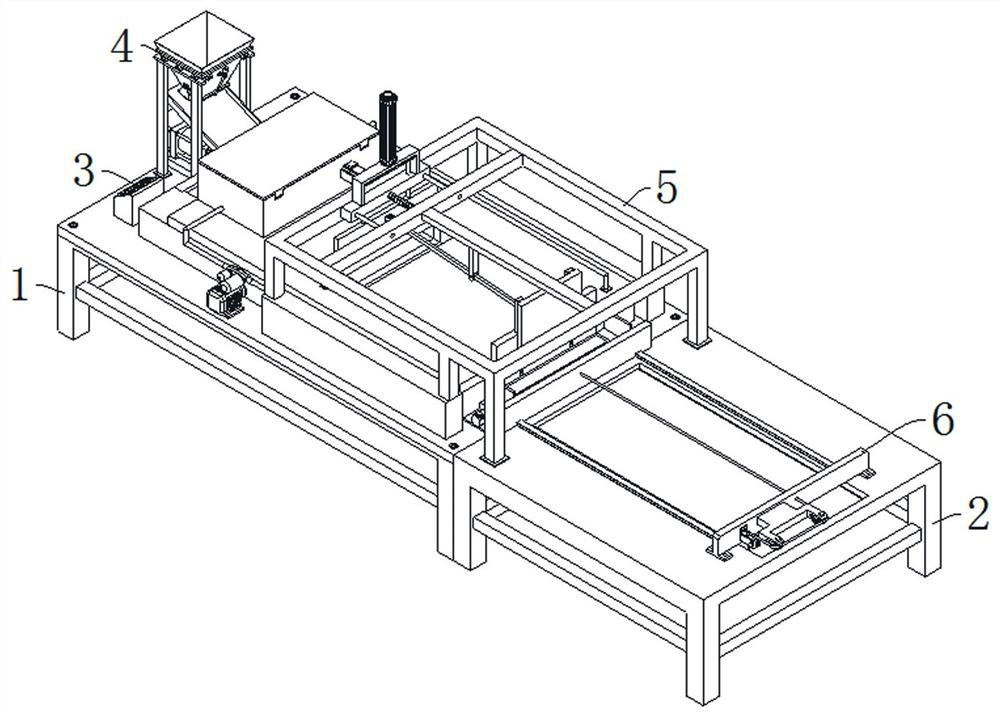

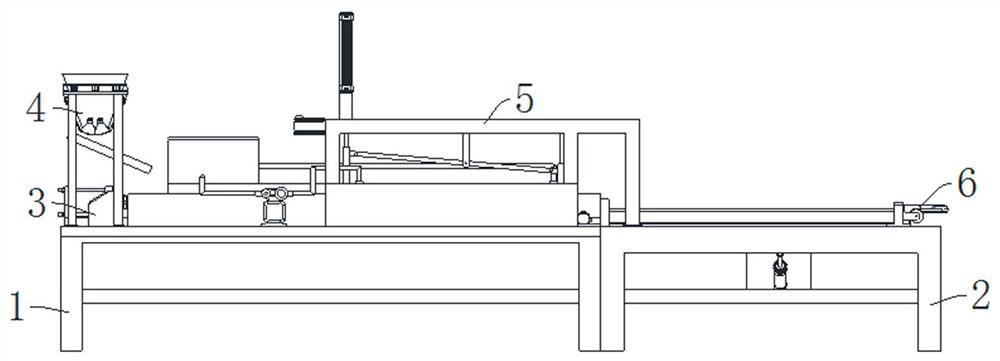

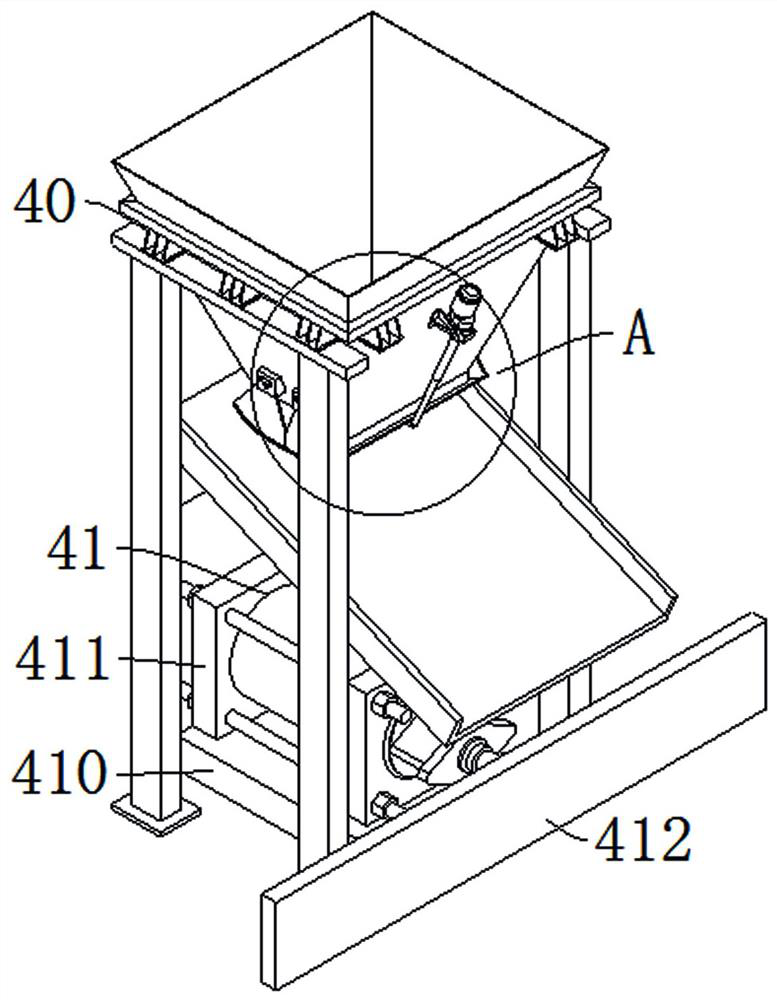

[0048] refer to Figure 1 to Figure 16 The shown device for rapid prototyping of polytetrafluoroethylene sheets includes a workbench 1 and an unloading table 2, and is characterized in that it also includes a controller 3, a feeding mechanism 4, a forming mechanism 5 and a conveying mechanism 6. The control The controller 3 is fixedly arranged on one side of the top of the workbench 1, and the feeding mechanism 4 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com