A prefabricated concrete formwork

A concrete prefabricated and assembled technology, applied in the direction of molds, manufacturing tools, mold fixtures, etc., can solve the problems of formwork tilting under force, affecting construction progress, single structure, etc., to meet stability needs, improve pouring control, improve The effect of support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in a variety of different ways of claim defined and covered.

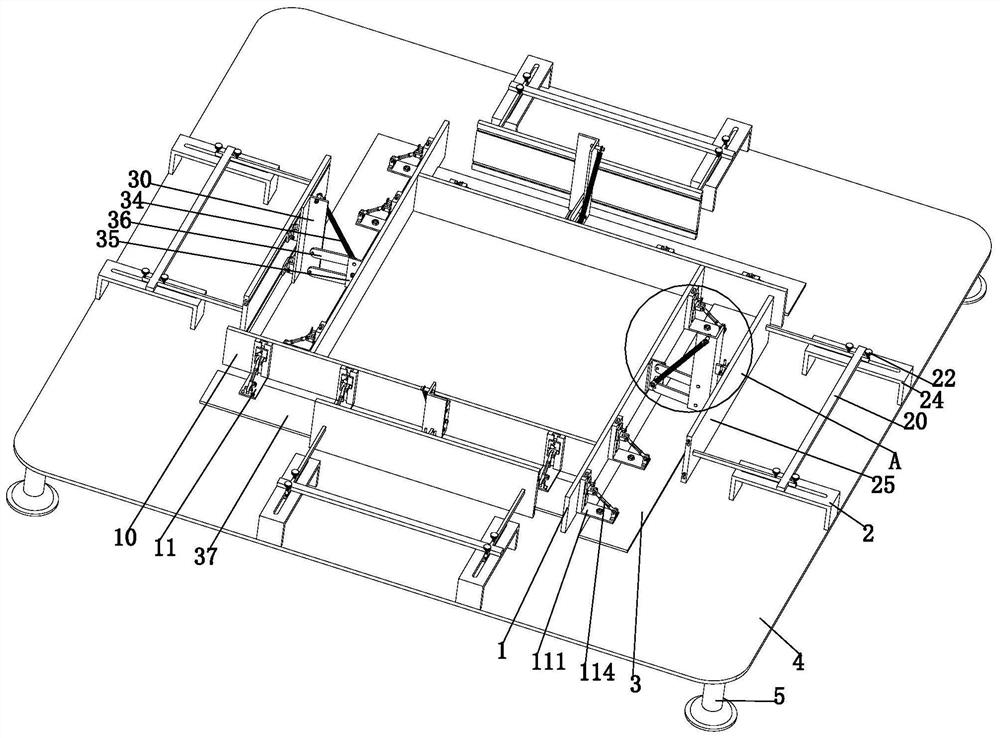

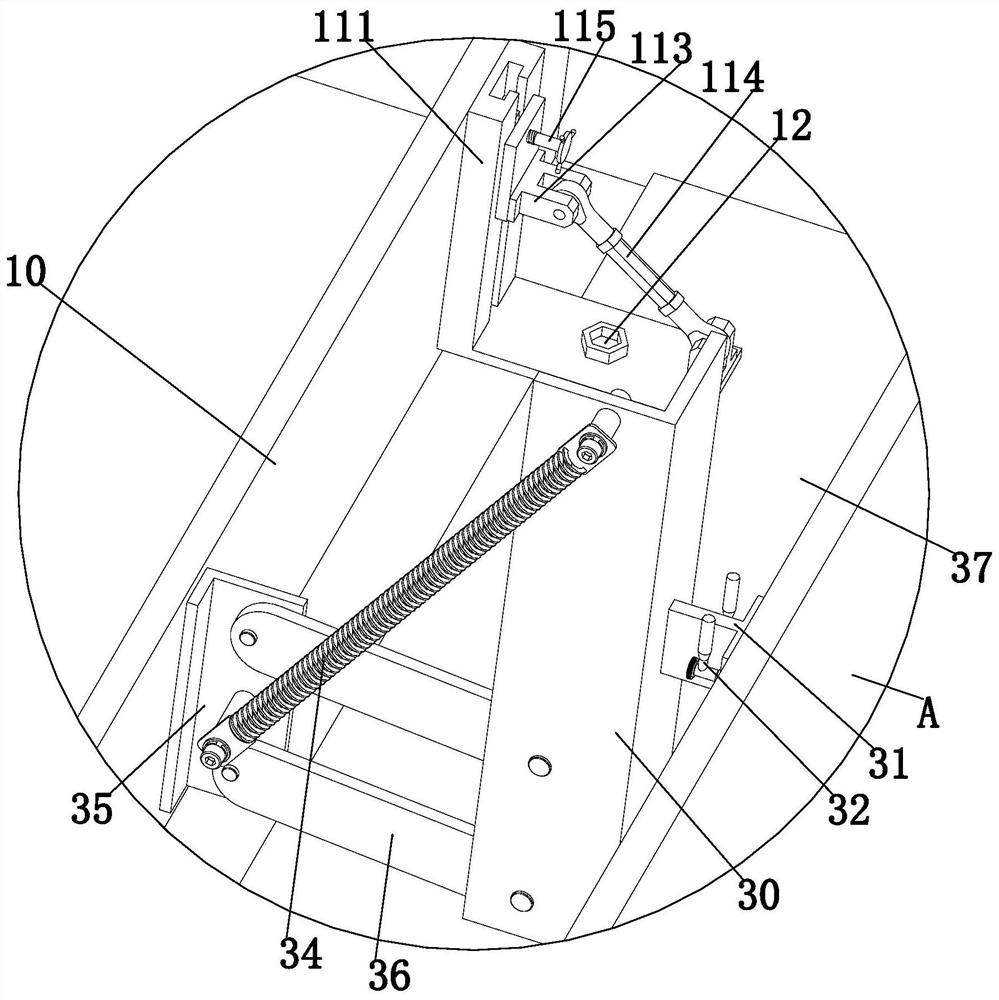

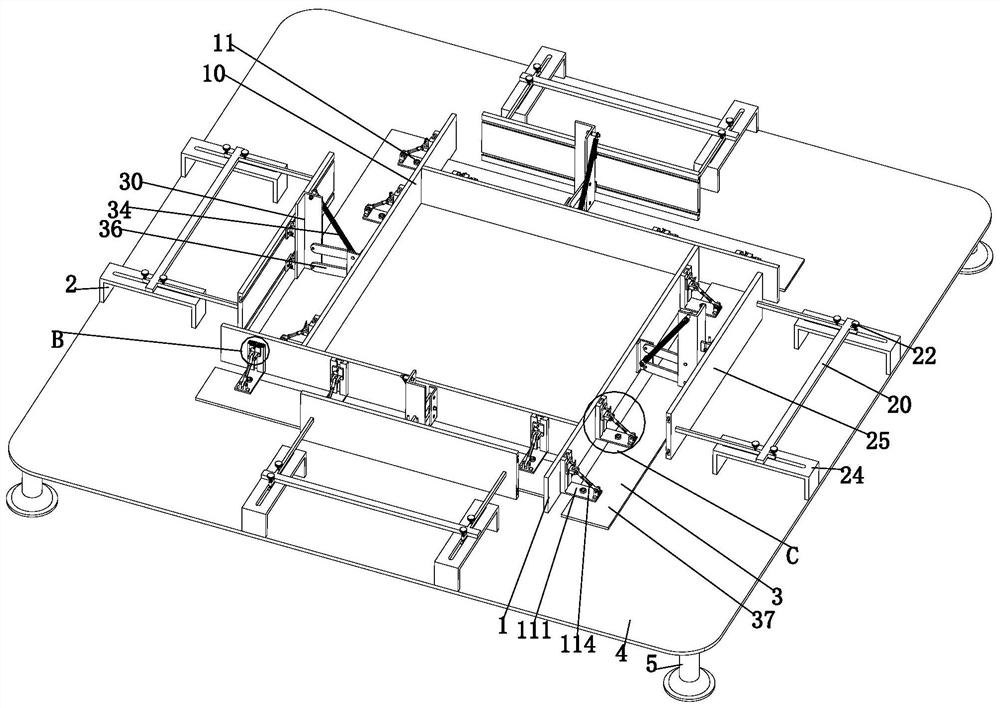

[0026] Such as Figure 1 to 8 As shown, an assembled concrete preform template includes a molding mechanism 1, a flat adjustment mechanism 2, a pulsise mechanism 3, a bottom plate 4, and a strut 5, and a plurality of sets of substrate 4 are disposed relative to a surround direction. The flat adjustment mechanism 2 is mounted by a sliding mechanism 3 in the inside of the flat mechanism 2, and is mounted in the inner side of the pulse mechanism 3, and the strut 5 is uniformly mounted on the bottom plate 4. On the end, where:

[0027] The molding mechanism 1 includes a bonding plate 10, a support unit 11, and a hex bolt 12; the bonding plate 10 is mounted on the L-type short plate 35, and a plurality of groups are provided in the longitudinal direction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com