Nanoscale water-based pigment dispersing liquid for ink jet and preparation method thereof

A water-based pigment and dispersion technology, applied in the direction of pigment paste, etc., can solve the problem of inkjet ink clogging the print head and other problems, and achieve the effect of meeting the needs of stability, low viscosity and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of ink-jet nano water-based pigment dispersion liquid of the present invention comprises the following steps:

[0030] 1. At room temperature (20°C), mix deionized water, dispersant 8-18%, and acid-base regulator 0.1-5%, preferably 1%, in a container according to mass percentage, stir and mix evenly in a container to obtain a mixed solution, stir The mixing speed is 300-500rpm, and the time is 10-30min.

[0031] The dispersant can be selected from one or more of solsperse-46000, edaplan482, solsperse-43000, zetasperse-3700, zetasperse-2500, EFKA4560, EFKA4585, Joncryl HPD196, Surfynol CT-151.

[0032] The acid-base regulator is more than one of triethanolamine, ammonia water, triethylamine and sodium hydroxide.

[0033] 2. Add 10-15% pigment by mass to the mixed solution under the condition of rotating speed 800-1000rpm to obtain the mixed solution with added pigment.

[0034] The pigment is one or more of yellow pigments, black pigments, red pi...

Embodiment 1

[0055] 1. According to the mass, disperse 8 parts of Basf dispersant EFKA4560, 1 part of triethanolamine and 81 parts of deionized water with a disperser at a speed of 300 rpm for 20 minutes to obtain a mixed solution.

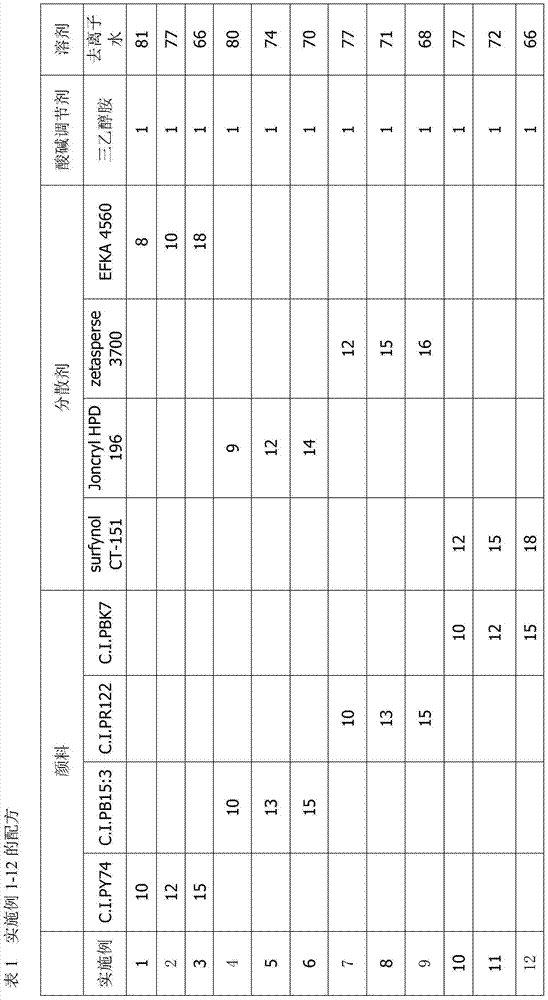

[0056] 2. Add 10 parts of yellow pigment C.I.PY74 from Ciba, a Swiss Basel chemical industry company, to the mixed solution at a rotational speed of 800 rpm to obtain a mixed solution with added pigment. The formulation composition is shown in Table 1.

[0057] 3. High-speed dispersion, the speed is 1000rpm, the time is 2.0h, and the dispersion liquid is obtained.

[0058] 4. Quickly pour the dispersion liquid into a horizontal pin mill with a 6.0L cavity, and circulate and grind 100kg of the dispersion liquid for 15 hours. The grinding medium is zirconia beads. The average diameter of zirconia beads is 0.2-0.5mm. 1000rpm, the mass ratio of zirconia beads to the dispersion liquid is 1:5, and the grinding temperature of the dispersion liquid is controlled betw...

Embodiment 2

[0063] 1. According to the mass, disperse 10 parts of Basf's dispersant EFKA4560, 1 part of triethanolamine and 77 parts of deionized water with a disperser at a speed of 420 rpm for 10 minutes to obtain a mixed solution.

[0064] 2. Add 12 parts of yellow pigment C.I.PY74 from Ciba Company to the mixed solution at a rotational speed of 900 rpm to obtain a mixed solution with added pigment. The formulation composition is shown in Table 1.

[0065] 3. High-speed dispersion, the speed is 1200rpm, the time is 1.5h, and the dispersion liquid is obtained.

[0066] 4. Quickly pour the dispersion liquid into a horizontal pin mill with a 6.0L cavity, and circulate and grind 100kg of the dispersion liquid for 15 hours. The grinding medium is zirconia beads. The average diameter of zirconia beads is 0.2-0.5mm. 1250rpm, the mass ratio of zirconia beads to the dispersion liquid is 1:5, and the grinding temperature of the dispersion liquid is controlled between 30-50°C during the grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com