Vertical forging and rough and finish turning process for driving spiral bevel gear with boss

A technology of spiral bevel gear and rough and fine turning, which is applied in the field of automobile driving bevel gear processing technology to achieve the effect of eliminating quality problems, uniform organization, and eliminating metal backflow and folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

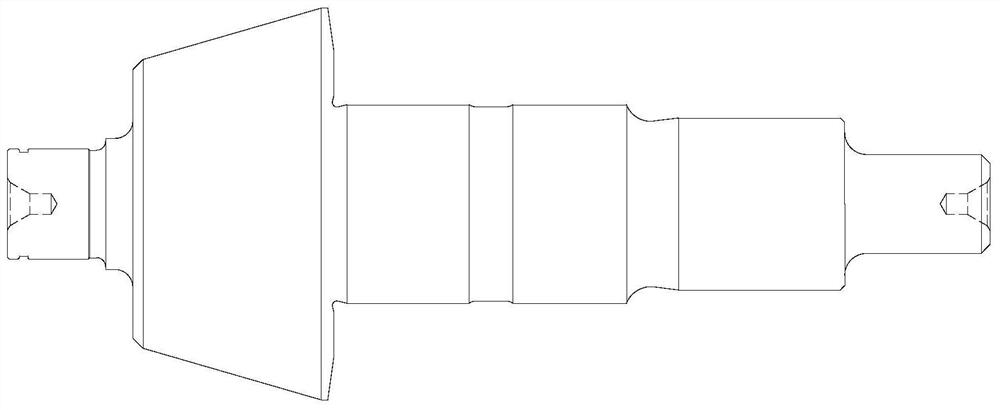

[0031] Such as Figure 1-Figure 7 As shown, the vertical forging and rough-finishing process of an active spiral bevel gear with a boss provided in this embodiment, the active spiral bevel gear is used for the rear axle of an automobile, and the vertical forging and rough-finishing process includes the following steps:

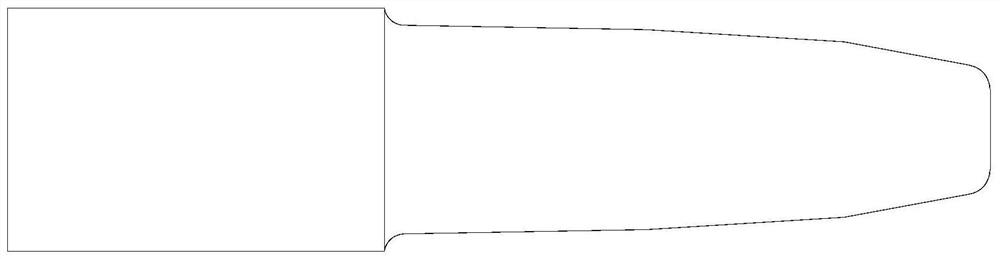

[0032] Step 1——Blanking: Select a round billet that meets the specifications according to the consumption quota. In this embodiment, a round billet with a diameter of 60mm is selected, such as figure 2 As shown, the round billet is heated to the initial forging temperature by using a 350KW medium frequency induction heating furnace;

[0033] Step 2 - Billet making: After the round billet is heated to the initial forging temperature, use a 560Kg air hammer to elongate one end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com