High Capacity Rod Mill

A rod mill, high-yield technology, applied in grain processing and other directions, can solve the problems of complex water treatment, high stone powder content, low output, etc., and achieve the effect of increasing processing capacity, avoiding water treatment, and reducing over-grinding phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better explain the content of the present invention, the technical solutions of the present invention are described below with reference to the accompanying drawings and through specific embodiments.

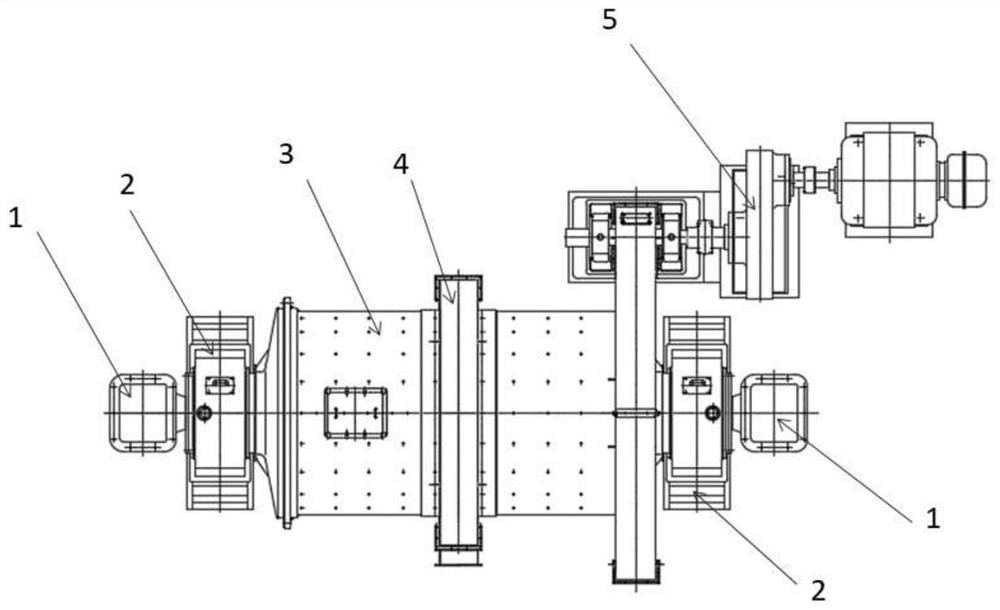

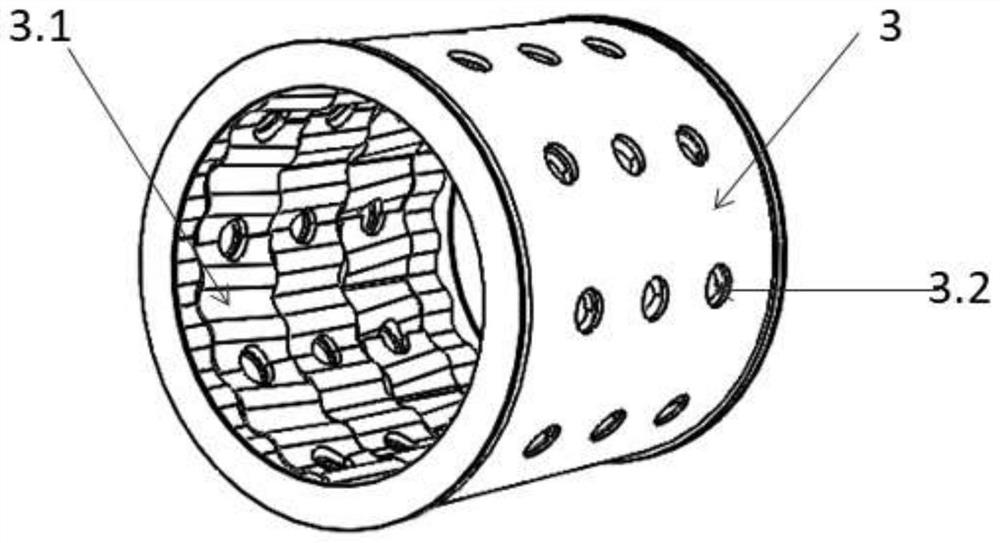

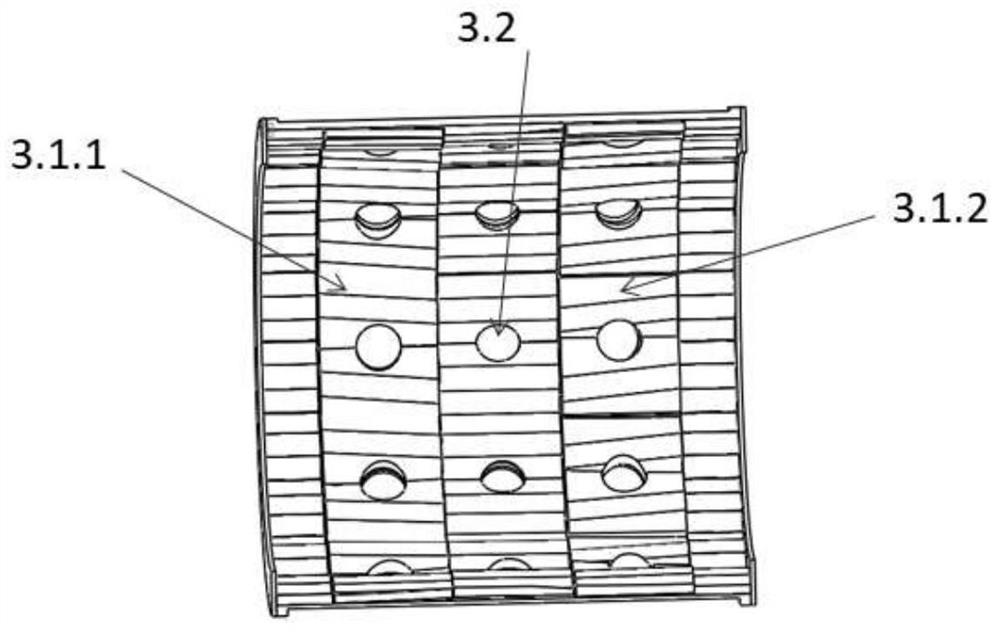

[0050] figure 1 Schematic diagram of the prior art rod mill. The prior art rod mill is usually composed of a cylinder body 3, a feeding part 1, a discharging part 4, a transmission device 5, a supporting part 2, a hydraulic system, a round bar, and the like. The cylinder body 3 is connected with the end cover and the hollow shaft. The bearing bush of the support part 2 supports the hollow shaft. The feeding part is communicated with the hollow shaft. Entering the cylinder, the round bar is loaded into the cylinder from the hollow shaft, the motor of the transmission system 5 drives the pinion, and the pinion drives the large gear on the cylinder 3 to rotate, the large gear drives the cylinder to rotate, and the cylinder drives the cylinder 3. The stone and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com