Synthesis and preparation of series of pillared metal organic framework materials and low-carbon hydrocarbon separation application of series of pillared metal organic framework materials

A pillared and series technology, which is applied in the field of synthesis and preparation of D-camphoric acid series pillared metal-organic framework materials, can solve problems such as restricting industrial applications and increasing production energy consumption, and achieves reduced energy consumption, low price, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

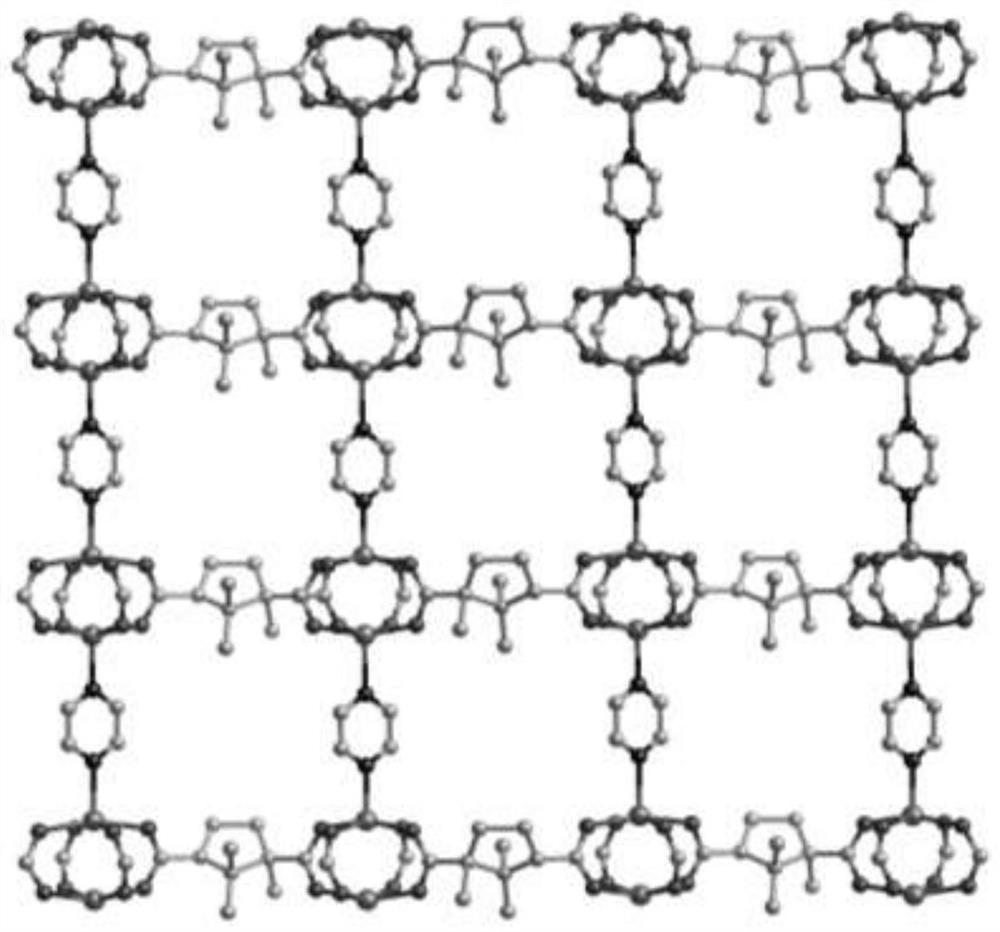

Image

Examples

Embodiment 1

[0041] Step 1: Weigh 10 mg D-camphoric acid, 16 mg pyrazine, and 20 mg anhydrous copper acetate, and dissolve them in a mixed solution of 3 mL N,N-dimethylacetamide (DMA), 3 mL water and 75 μL tetrafluoroboric acid. After sonicating and obtaining a homogeneous solution, it was then transferred into a 20mL glass reaction vial, and subjected to a constant temperature reaction at 95°C for 48h to obtain the Cu-cam-pyz crystalline sample with a yield of 70% (calculated based on the metal salt).

Embodiment 2

[0043] Step 1: Weigh 10 mg of D-camphoric acid, 28 mg of pyrazine, and 29 mg of cobalt nitrate hexahydrate, and dissolve them in 8 mL of N,N-dimethylacetamide (DMA). After sonicating and obtaining a homogeneous solution, it was then transferred into a 20mL glass reaction vial and subjected to a constant temperature reaction at 95°C for 48h to obtain the Co-cam-pyz crystalline sample with a yield of 66% (calculated based on the metal salt).

Embodiment 3

[0045] Step 1: Weigh 10 mg of D-camphoric acid, 16 mg of pyrazine, and 15 mg of nickel nitrate hexahydrate, and dissolve them in 5 mL of N,N-dimethylformamide (DMF). After sonicating and obtaining a homogeneous solution, it was then transferred into a 20mL glass reaction vial, and subjected to a constant temperature reaction at 120°C for 48h to obtain the Ni-cam-pyz crystalline sample with a yield of 50% (calculated based on the metal salt).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com