A hollow ferric oxide@air@carbon nanocomposite wave-absorbing material of egg yolk shell and its preparation method

A technology of ferroferric oxide and carbon nanocomposite, applied in shielding materials, electrical components, magnetic field/electric field shielding, etc., can solve problems affecting the normal operation of the immune system, leakage of secret electromagnetic signals, and increased risk of disease, and achieve easy Adjustable absorbing performance, low filling ratio, easy to synthesize in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

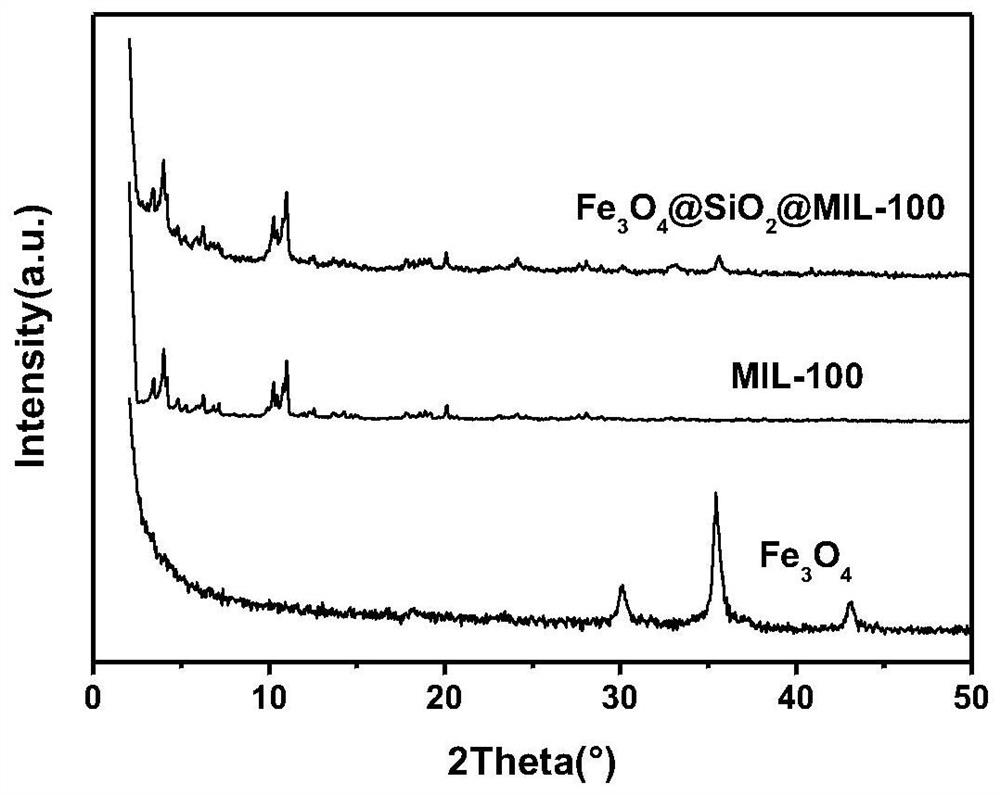

[0036] (1) Weigh 3.2436 g of ferric chloride hexahydrate, 7.0584 g of sodium citrate dihydrate and 2.1624 g of urea, dissolve them in 210 mL of deionized water in sequence, then add 1.8 g of polyacrylamide, and stir the solution at room temperature for 5 h until uniform After clarification, the polytetrafluoroethylene-lined autoclave was kept at 200°C for 10 hours, and the obtained black muddy product was washed 5 times with deionized water and 3 times with absolute ethanol, and dried at 60°C, which was hollow trioxide. Iron nanoparticles;

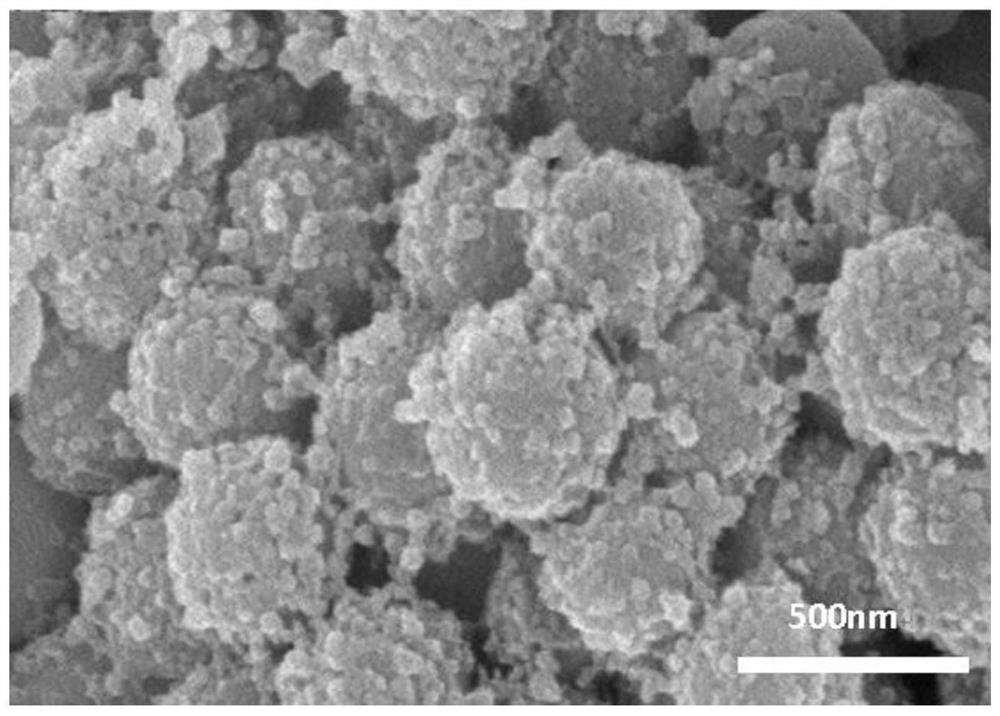

[0037] (2) Weigh 300 mg of hollow Fe3O4 nanoparticles and disperse in 150 mL of ethanol and 50 mL of deionized water mixed solution, ultrasonically disperse for 30 min, add 4 mL of concentrated ammonia water (25 wt / %), and stir mechanically for 5 min, add 1 mL of TEOS (tetraethyl orthosilicate), and add it once every 30 min, add 3 times in total, stir mechanically for 6 h, wash the obtained product with ethanol 5 times, and dry at 60°C to ...

Embodiment 2

[0046] The difference between Example 2 and Example 1 is that in step (5), the calcination temperature is 700°C, and the rest of the process conditions are identical, and the black product obtained in this example is named P-700.

[0047] The egg yolk shell hollow iron tetroxide@air@carbon nanocomposite absorbing material (P-700) prepared in this example is mixed with paraffin, the proportion of paraffin is 70wt%, and pressed in a special mold to have an outer diameter of 7.00 mm , a coaxial sample with an inner diameter of 3.04 mm and a thickness of about 2 mm. The mass fraction of the product is 30%. Use the N5224A vector network analyzer to test its electromagnetic parameters, and calculate the absorbing performance. The test frequency range is 2-18 GHz.

[0048] The variation curve of reflection loss of sample P-700 with frequency is shown as Figure 4 As shown, when the coating thickness is 3 mm, the maximum absorption intensity of the composite material can reach -27.7 d...

Embodiment 3

[0050] The difference between Example 3 and Example 1 is that in step (5), the calcination temperature is 800°C, and the rest of the process conditions are identical, and the black product obtained in this example is named P-800.

[0051] The egg yolk shell hollow iron tetroxide@air@carbon nanocomposite absorbing material (P-800) prepared in this example is mixed with paraffin, the proportion of paraffin is 70wt%, and it is pressed into a special mold with an outer diameter of 7.00 mm , a coaxial sample with an inner diameter of 3.04 mm and a thickness of about 2 mm. The mass fraction of the product is 30%. Use the N5224A vector network analyzer to test its electromagnetic parameters, and calculate the absorbing performance. The test frequency range is 2-18 GHz.

[0052] When the coating thickness is 5.5 mm, the maximum absorption intensity of the egg yolk shell hollow ferric oxide@air@carbon nanocomposite absorbing material prepared in this example can reach -25 dB, and the ef...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com