Battery heating assembly and manufacturing process thereof

A battery heating and electromagnetic heating coil technology, applied in induction heating, electrical components, secondary batteries, etc., can solve problems such as poor battery life and poor battery power supply, and achieve improved service life, extended battery life, and improved The effect of battery activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

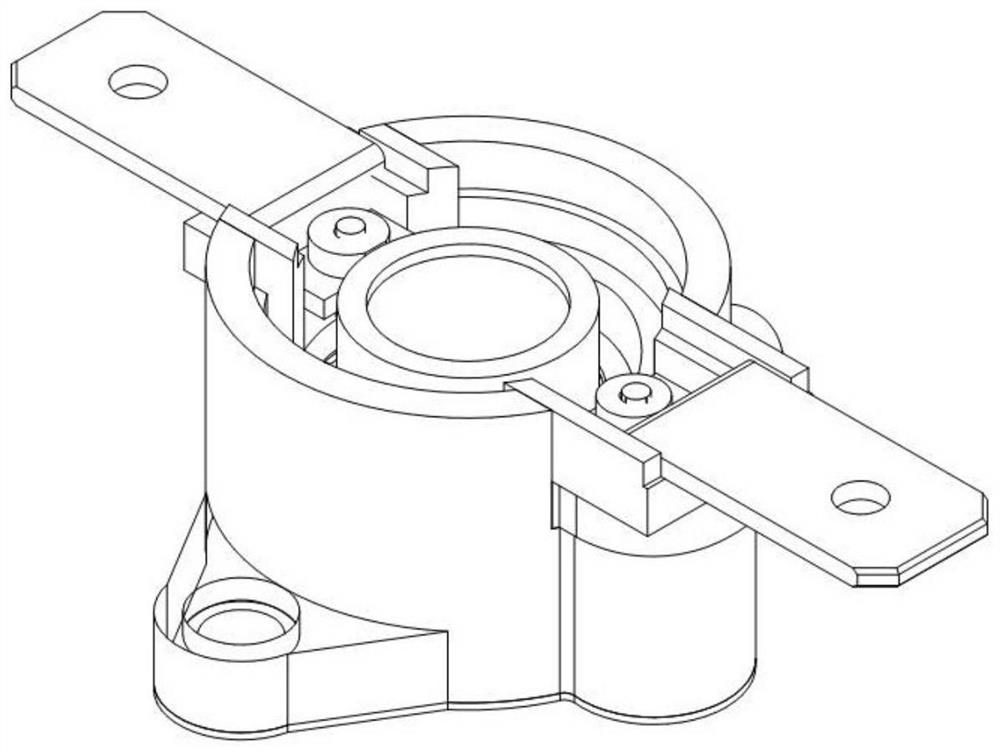

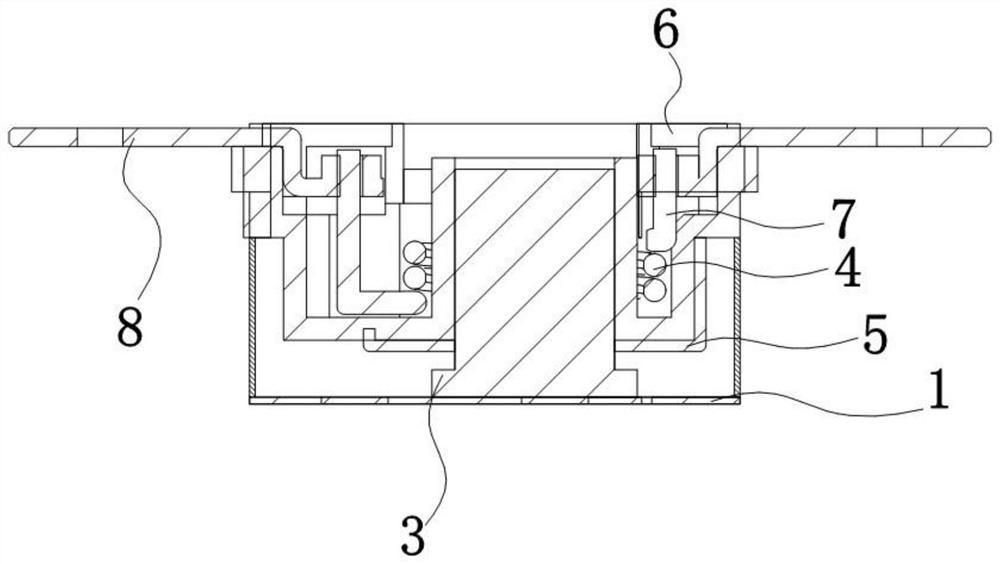

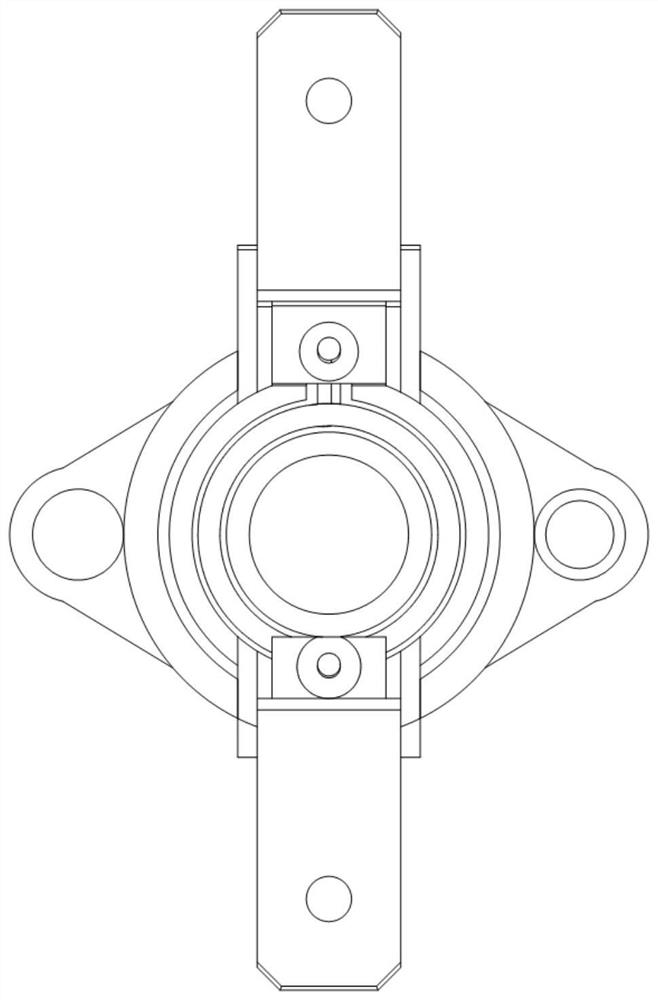

[0028] A battery heating component such as Figure 1 to Figure 4 As shown, it includes a bottom bracket 1 as a base, a bushing assembly, a metal core 3 for heat transfer and an electromagnetic heating coil 4 for heating the metal core are arranged in the bottom bracket 1, and the bottom of the metal core 3 is set on the On the bottom support 1, the electromagnetic heating ring can be sleeved on the outside of the metal core or through the bushing assembly to achieve stable assembly. After the electromagnetic heating ring is energized, the metal core is heated, and the heat of the metal core is transferred out for heating. The bottom support Made of thermally conductive metal material to facilitate heat transfer.

[0029] In this embodiment, the metal core can be heated by the electromagnetic heating ring, and the metal core also has the function of heat transfer. During the heat transfer process, the battery in the battery compartment of the new energy vehicle can be heated. I...

Embodiment 2

[0044] A manufacturing process of a battery heating component, comprising the following steps:

[0045] Place the one-piece heat-transmitting metal bottom support on the bottom, use the bottom support as the base, and then place the metal core in the cavity of the bottom support, then put the first bushing on the metal core, and place the first bushing on the metal core. Put it on and then assemble the second bush made of non-metallic material. The second bush realizes the assembly position relationship of the metal core, the first bush and the bottom bracket through the positioning part, the positioning groove and the assembly opening, and assembles the second bush Finally, assemble the electromagnetic heating coil with binding posts, assemble the binding posts connected by the two ends of the electromagnetic heating coil in the insertion groove, and then assemble the lead terminals.

[0046] As a more specific design, the width of the lead terminal matches the width of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com