Ni-Cr alloy temperature sensor based on magnetostrictive torsional waves

A temperature sensor and magnetostrictive technology, applied in the field of temperature sensors, can solve the problems of low Curie temperature and easy oxidation, and achieve the effects of weak thermal expansion, easy detection, and less energy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

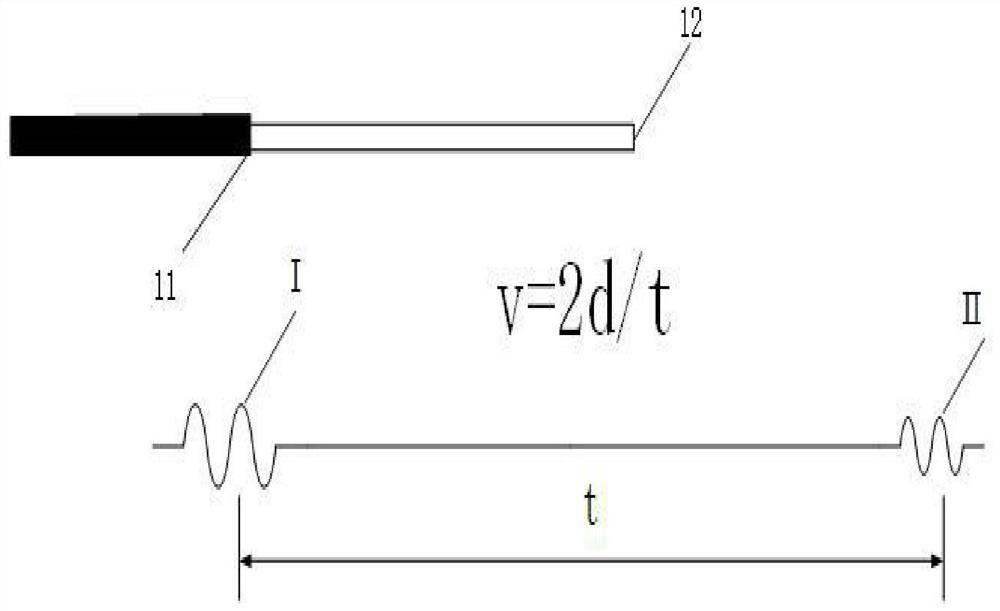

[0073] Example 1: Put the chromium-nickel alloy wire part of the sensor into a high-temperature furnace, heat it at room temperature -1000°C, and detect the change between the two waveforms through the detection coil, and the time difference between the two stress wave peaks is hours delay. The main purpose of this embodiment is to study the relationship between the delay value and the temperature as the temperature rises.

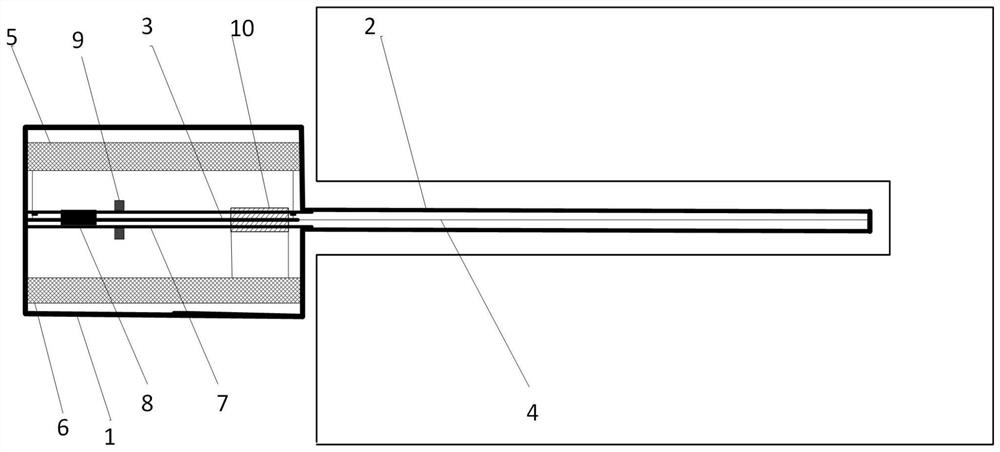

[0074] Experimental platform construction: according to figure 1 The temperature sensor structure shown is installed with various components, and the installed temperature sensor is placed in a high-temperature furnace. As the temperature rises, an oscilloscope is used to observe the output waveform of the detection coil.

[0075] The software or protocols involved in the present invention are all known technologies.

[0076] Experimental process and results: such as Figure 5 As shown, the output voltage curve of the detection coil at 20°C is obtained....

Embodiment 2

[0078] Embodiment 2: use Fe-Ga and a permanent magnet as the torsional wave signal generator, other parts are the same as embodiment 1 in structure, the difference is that the measuring rod is Figure 4 The chromium-nickel alloy wire is flexible and can be bent deep into the measuring rod in the shape of a flat disc. Put the flat measuring rod into a cylindrical high-temperature furnace with a diameter of 240 mm and heat it at room temperature -1000 ° C. Detect changes in the waveform. The main purpose of this embodiment is to verify the reliability of the device signal at high temperature, and to calculate the sound velocity of the torsional wave at different temperatures.

[0079] Experimental platform construction: according to Figure 4 The temperature measuring sensor structure shown is to install various components, and the installed temperature measuring sensor is put into a high temperature furnace. Other steps are the same as in Embodiment 1, and the output waveform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The maximum diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com