Double-sided plasma enhanced chemical vapor deposition structure and deposition device

A plasma and enhanced chemical technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of low deposition efficiency and complicated operation, and achieve high efficiency, strong applicability and excellent deposition effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

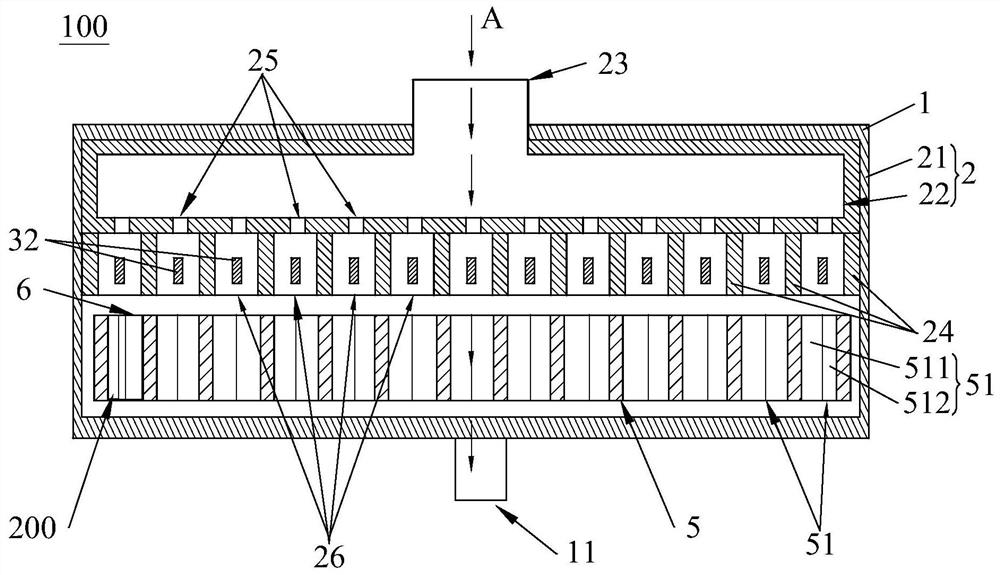

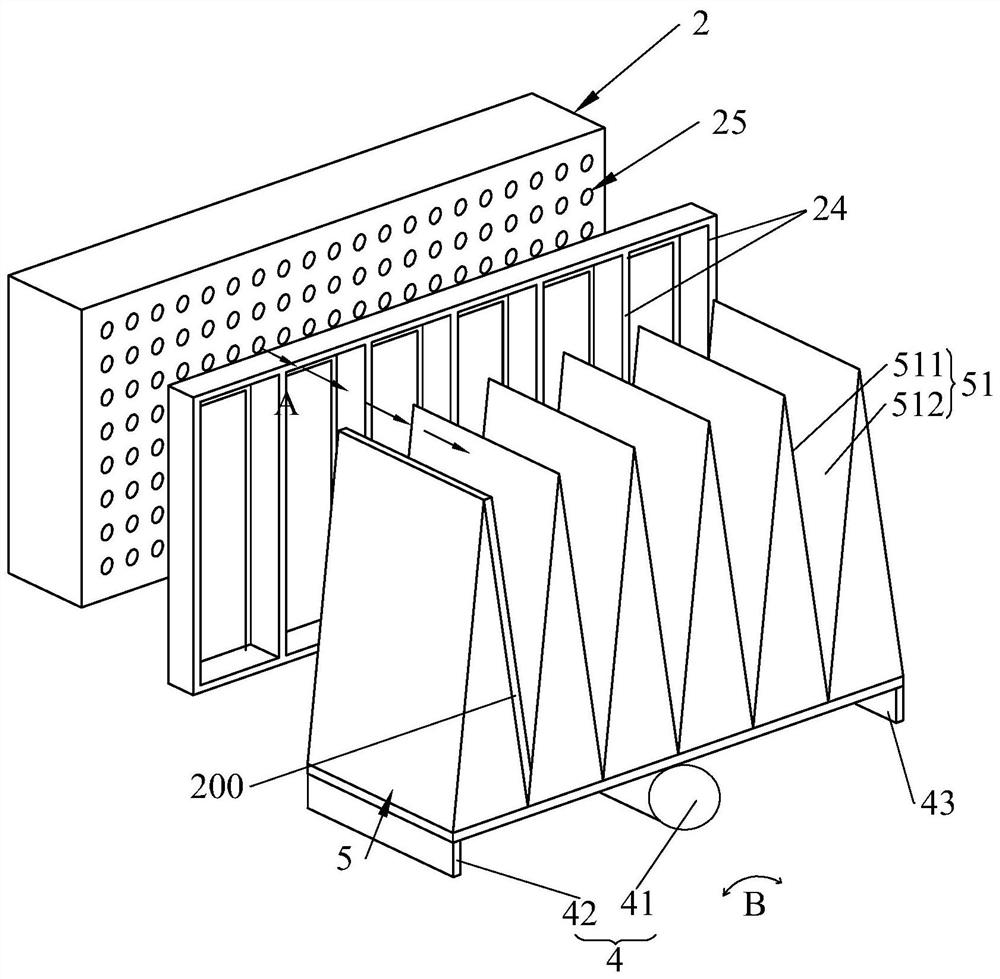

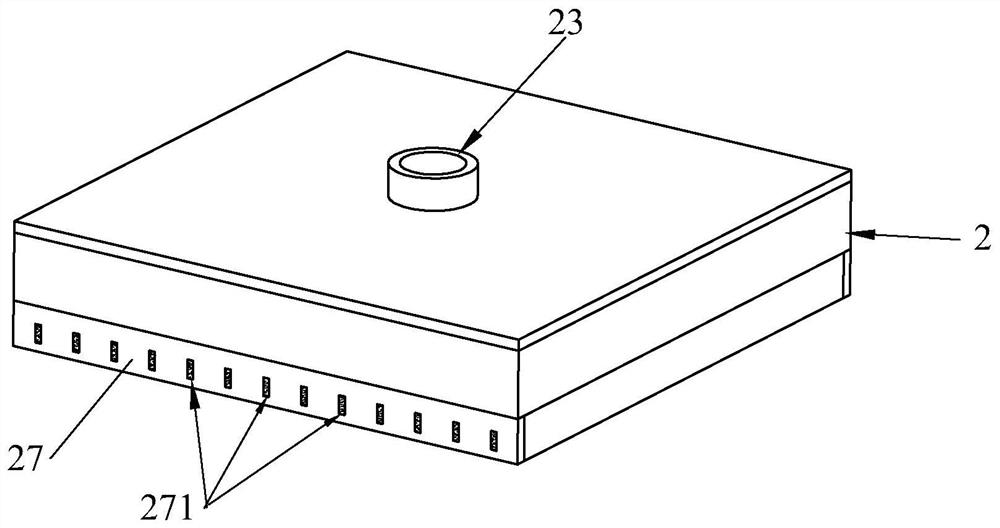

[0025] see Figure 1 to Figure 5 , the deposition device of the present invention includes a gas collection chamber (not shown) and a double-sided plasma-enhanced chemical vapor deposition structure 100, the double-sided plasma-enhanced chemical vapor deposition structure 100 is symmetrically arranged, and all double-sided plasma-enhanced chemical vapor deposition The pumping ports 11 of the structure 100 are all connected to the gas collection chamber, so that one gas collection chamber can collect the gas discharged from multiple double-sided plasma-enhanced chemical vapor deposition structures 100, which saves space and is more convenient for recycling. Among them, The double-sided plasma-enhanced chemical vapor deposition structure 100 includes a box body 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com