High-temperature self-transformation amorphous/nanocrystalline high-entropy oxide film, preparation method and application

An oxide film and nanocrystal technology, applied in the field of protective coatings, achieves the effects of rich structure-activity relationship regulation space, excellent mechanical properties, and good oxygen barrier effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

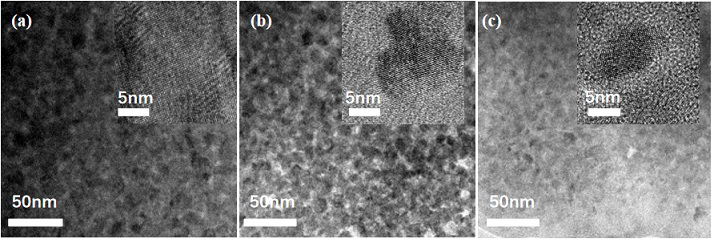

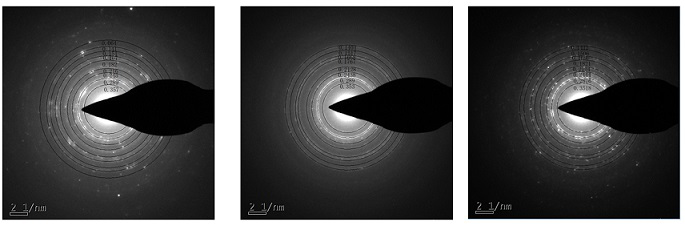

Embodiment 1

[0034] The preparation of Zr-Cr-Nb-Al-Fe(O) oxide film, the steps are as follows:

[0035] (1) Cut and combine Zr-Cr-Nb into a new sputtering target, Al-Fe into another new sputtering target, and use the two combined targets as sputtering targets; use single crystal The silicon wafer was used as the coating substrate, and the substrate was ultrasonically treated with acetone, alcohol, and deionized water for 20 minutes, and then dried with a high-purity nitrogen air gun for later use; when the vacuum degree of the chamber reached 5×10 -4 Start to deposit at around mbar;

[0036] (2) Pre-sputtering: The sputtering target material cut and combined by Zr-Cr-Nb is connected to the target position connected to the direct current (DC) power supply. The sputtering target material cut and assembled by Al-Fe is connected to the target position connected to the radio frequency (RF) power supply, and the air pressure in the chamber reaches 5×10 -4 When it is below Pa, open the process...

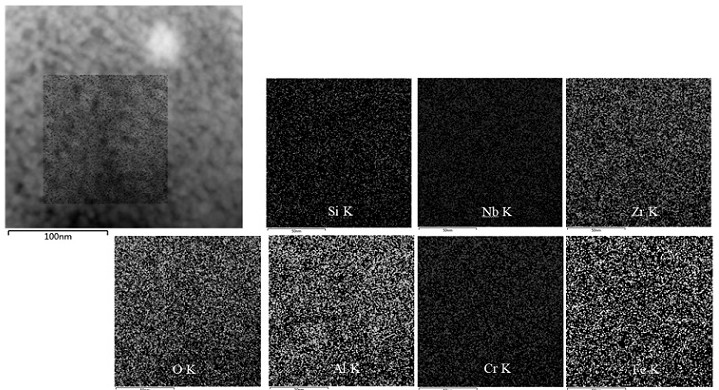

Embodiment 2

[0040] The preparation of Zr-Cr-Nb-Al-Fe-Si(O) amorphous nanocrystalline oxide film, the steps are as follows:

[0041] (1) Combine Zr-Cr-Nb cutting into a new sputtering target, Al-Fe-Si cutting into another new sputtering target, and the two combined targets as sputtering targets; The crystalline silicon wafer was used as the coating substrate, and the substrate was ultrasonically treated with acetone, alcohol, and deionized water for 20 minutes, and then dried with a high-purity nitrogen air gun for later use; when the vacuum degree of the chamber reached 5×10 -4 Start to deposit at around mbar;

[0042] (2) Connect the sputtering target formed by Zr-Cr-Nb cutting and combination to the target position connected to the direct current (DC) power supply. The sputtering target material cut and combined by Al-Fe-Si is connected to the target position connected to the radio frequency (RF) power supply. The air pressure in the chamber reaches 5×10 -4 When it is below Pa, open ...

Embodiment 3

[0046] The preparation of Zr-Cr-Nb-Al-Fe-Si(O) amorphous nanocrystalline oxide film, the steps are as follows:

[0047] (1) Combine Zr-Cr-Nb cutting into a new sputtering target, Al-Fe-Si cutting into another new sputtering target, and the two combined targets as sputtering targets; The crystalline silicon wafer was used as the coating substrate, and the substrate was ultrasonically treated with acetone, alcohol, and deionized water for 20 minutes, and then dried with a high-purity nitrogen air gun for later use; when the vacuum degree of the chamber reached 5×10 -4 Start to deposit at around mbar;

[0048] (2) Pre-sputtering: The sputtering target material cut and combined by Zr-Cr-Nb is connected to the target position connected to the direct current (DC) power supply. The sputtering target material cut and combined by Al-Fe-Si is connected to the target position connected to the radio frequency (RF) power supply. The air pressure in the chamber reaches 5×10 -4 When it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com