A high-temperature, high-humidity, high-pressure, acid-alkali-resistant, high-adhesion roll-spray coating

A technology with high adhesion and acid and alkali resistance. It is applied in the field of acid and alkali resistant high adhesion roller spray coating, high temperature, high humidity and high pressure resistance. It can solve the problems of low coating adhesion, failure to achieve insulation, and slow curing speed. Achieve the effect of no damage to the appearance, uniform thickness and high TG value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

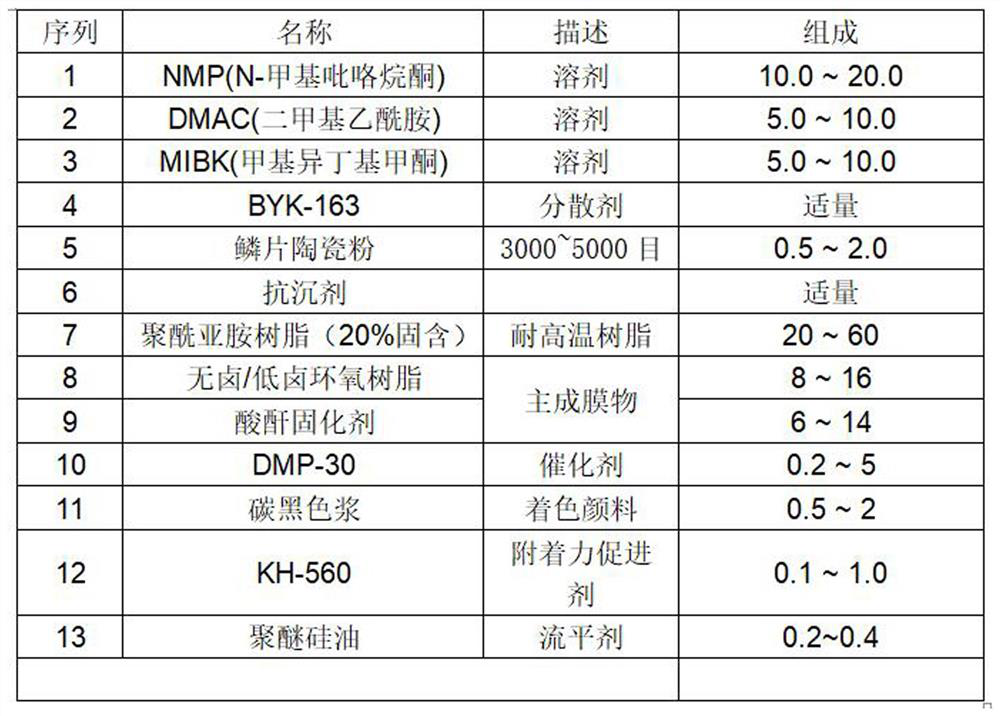

[0026] The high-temperature, high-humidity and high-pressure resistant, acid-alkali-resistant and high-adhesion roll-spray coating described in this embodiment, the components by mass of the roll-spray coating composition are: 11 parts of N-methylpyrrolidone, 6 parts of dimethylacetamide , 6 parts of methyl isobutyl ketone, 3 parts of BYK-163, 0.8 parts of flake ceramic powder, 2 parts of anti-settling agent, 30 parts of polyimide resin, 10 parts of halogen-free / low-halogen epoxy resin, 7 parts of anhydride curing agent 1 part, DMP-30 1 part, carbon black paste 0.8 part, KH-560 0.3 part, polyether silicone oil 0.2 part.

[0027] The application principle of selecting each component of the above formula is:

[0028] 1. Thinner: The paint should not dry too quickly during the high-temperature rolling spraying process. If the diluent volatilizes too quickly, the paint will evaporate before it is sprayed on the surface of the part, and the surface of the part will be dusty and th...

Embodiment 2

[0051]The difference between this example and Example 1 is that the parts by mass of each component of the roll-spray coating composition are: 18 parts of N-methylpyrrolidone, 7 parts of dimethylacetamide, 8 parts of methyl isobutyl ketone, BYK -163 12 parts, flake ceramic powder 1.35 parts, anti-settling agent 11.2 parts, polyimide resin 53 parts, halogen-free / low-halogen epoxy resin 14.5 parts, anhydride curing agent 12.8 parts, DMP-30 4.2 parts, carbon black 1.3 parts of slurry, 0.9 parts of KH-560, and 0.38 parts of polyether silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com