Preparation method of modified rubber powder

A technology for modifying rubber and rubber powder, which is applied in the field of rubber and can solve the problems of further improvement in performance, achieve the effects of improving mechanical properties, improving wear resistance and mechanical properties, and avoiding internal agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

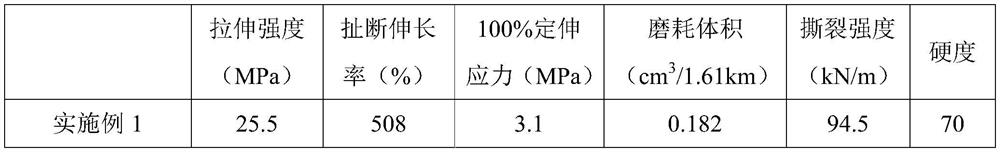

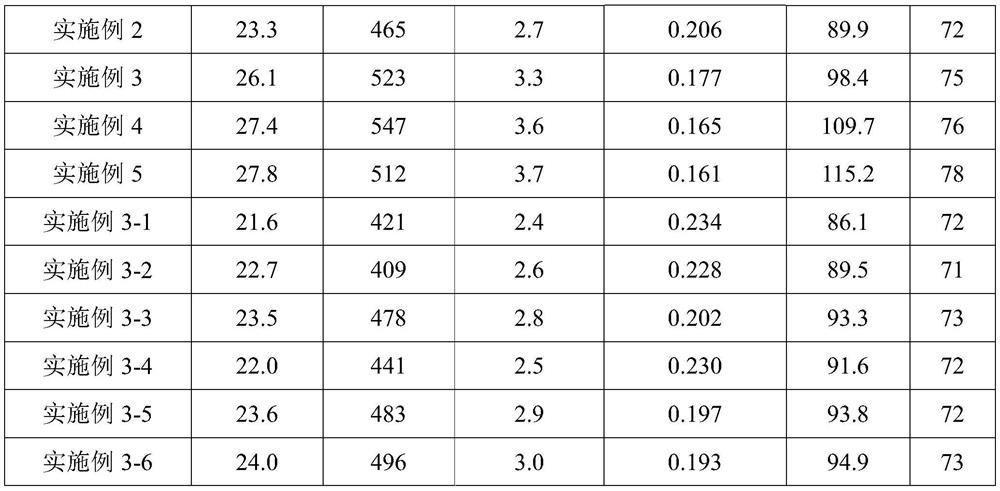

Examples

Embodiment 1

[0043] A preparation method of modified rubber powder, comprising the steps of:

[0044] (1) coarsely crushing waste and old natural rubber, removing impurities, and then pulverizing to further remove impurities to obtain 20 order rubber powder;

[0045] (2) Rubber powder obtains substance A under microwave action; The power of microwave is 200W, and the action time of microwave is 15min;

[0046](3) Add substance A into dichloromethane, heat to 30°C, the ratio of the volume of dichloromethane to the mass of rubber powder is 5mL / g, mix with initiator and modifier, filter after 2h, and dry in vacuum, that is have to;

[0047] The initiator is a mixture of benzoyl peroxide-N,N-dimethylaniline system and dimethyl azobisisobutyrate, benzoyl peroxide-N,N-dimethylaniline system (over The mass ratio of benzoyl oxide and N,N-dimethylaniline is 2:1), and the quality is 0.05% of the rubber powder quality, and the quality of dimethyl azobisisobutyrate is 0.01% of the rubber powder qual...

Embodiment 2

[0050] A preparation method of modified rubber powder, comprising the steps of:

[0051] (1) the waste styrene-butadiene rubber is coarsely crushed to remove impurities, and then pulverized to further remove impurities to obtain 150 order rubber powder;

[0052] (2) Rubber powder obtains substance A under microwave action; The power of microwave is 400W, and the action time of microwave is 30min;

[0053] (3) Add substance A into cyclohexane, heat to 70°C, the ratio of the volume of cyclohexane to the mass of rubber powder is 10mL / g, mix with initiator and modifier, filter after 1h, and dry in vacuum, that is have to;

[0054] The initiator is a mixture of benzoyl peroxide-N,N-dimethylaniline system and dimethyl azobisisobutyrate, benzoyl peroxide-N,N-dimethylaniline system (over The mass ratio of benzoyl oxide and N,N-dimethylaniline is 4:1), and the quality is 0.1% of the rubber powder quality, and the quality of dimethyl azobisisobutyrate is 0.04% of the rubber powder qua...

Embodiment 3

[0057] A preparation method of modified rubber powder, comprising the steps of:

[0058] (1) coarsely crushing waste and old natural rubber, removing impurities, and then crushing to further remove impurities to obtain 100 mesh rubber powder;

[0059] (2) Rubber powder obtains substance A under microwave action; The power of microwave is 300W, and the action time of microwave is 20min;

[0060] (3) Add substance A into toluene, heat to 100°C, the ratio of the volume of toluene to the mass of rubber powder is 8mL / g, mix with initiator and modifier, filter after 1.5h, and dry in vacuum to obtain final product;

[0061] The initiator is a mixture of benzoyl peroxide-N,N-dimethylaniline system and dimethyl azobisisobutyrate, benzoyl peroxide-N,N-dimethylaniline system (over The mass ratio of benzoyl oxide and N,N-dimethylaniline is 3:1), and the quality is 0.08% of the rubber powder quality, and the quality of dimethyl azobisisobutyrate is 0.02% of the rubber powder quality;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com