Peony flower flavored sunflower seed preparation equipment and preparation method thereof

A technology for sunflower seeds and peony flowers, which is applied to peony flower-flavored sunflower seeds preparation equipment and the field of preparation thereof, can solve the problems of increasing enterprise costs, laborious work efficiency, and not being together, so as to improve quality, avoid water pollution, and avoid accumulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

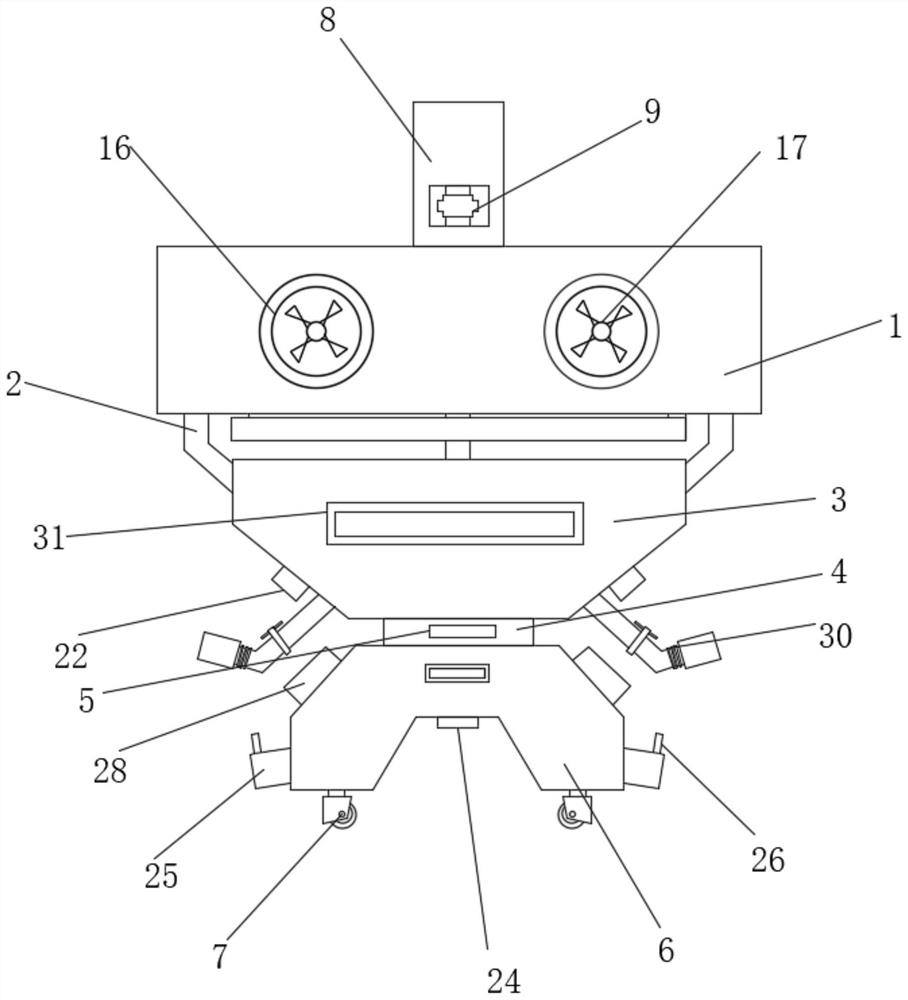

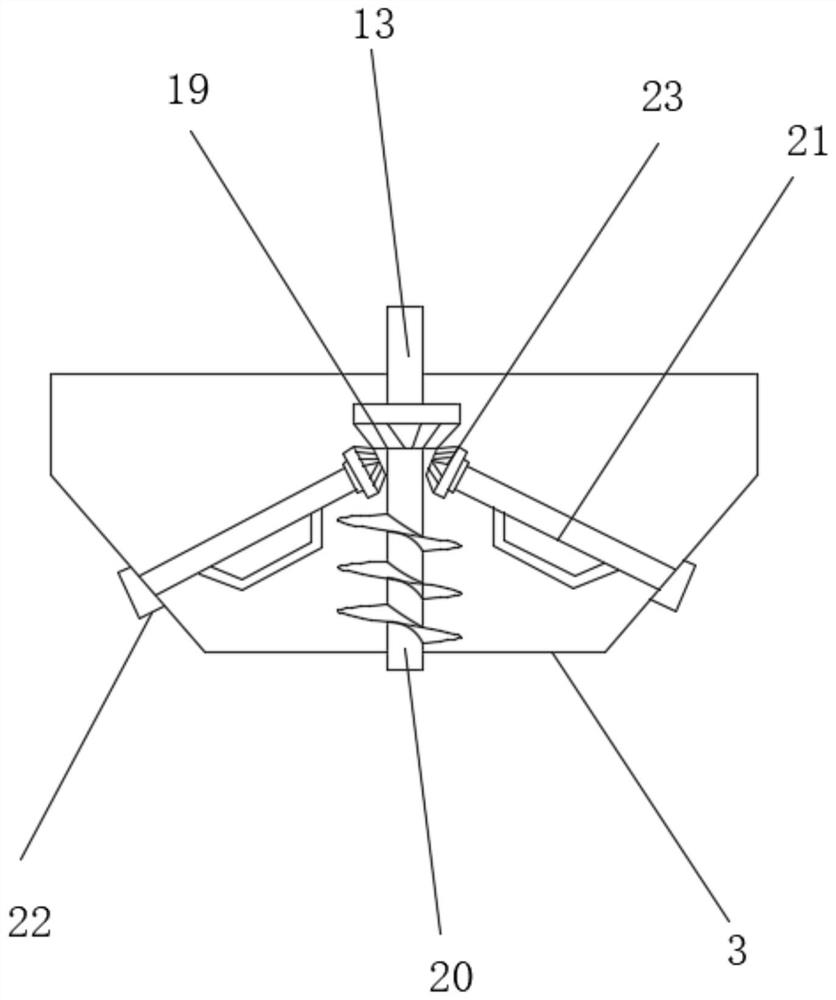

[0031]The equipment for preparing peony-flavored sunflower seeds includes a screening box 1, the bottom of the screening box 1 is fixedly connected with a fixing frame 2, the bottom of the fixing frame 2 is fixedly installed with a soaking tube 3, and the bottom of the soaking tube 3 is connected with a connecting pipe 4, The side of the connecting pipe 4 is provided with a valve 5, the valve 5 is an electric valve, and the bottom of the connecting pipe 4 is equipped with a drying box 6, the top of the screening box 1 is fixedly installed with a driver 8, and the output shaft of the driver 8 is fixedly connected with a Coupling 9, the other end of coupling 9 is fixedly connected with linkage rod 13, and the inner side of screening box 1 is fixedly installed with coarse screen 11 and fine screen 12 respectively, and coarse screen 11 is positioned at the front of fine screen 12. Above, the front of the screening box 1 is provided with an air inlet 16, and the inside of the air in...

Embodiment 2

[0033] The bottom of drying box 6 is fixedly installed with self-locking wheel 7, and the quantity of self-locking wheel 7 is four, and the distribution of four self-locking wheels 7 annular arrays is in the bottom of drying box 6, can know from above-mentioned structure, self-locking wheel 7 Locking wheel 7 can facilitate the movement of this equipment.

Embodiment 3

[0035] The top of the screening box 1 is provided with a discharge chute 10, the discharge chute 10 is annular and the bottom of the discharge chute 10 is provided with a feed hole. Groove 10, discharge chute 10 can be convenient for the worker to pour sunflower seeds in the screen cloth, and the coarse screen cloth 11 and fine screen cloth 12 installed in screening box 1 inner side can carry out multistage screening to sunflower seed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com