Manufacturing packaging method of electrochromic anti-dazzle device for vehicle

A technology of electrochromism and encapsulation method, which is applied in the directions of vehicle parts, optical observation devices, transportation and packaging, etc., can solve the problems of mutual extrusion and infiltration, increasing process difficulty, and construction technology difficulty, so as to increase the cross-sectional area, The effect of easy process and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

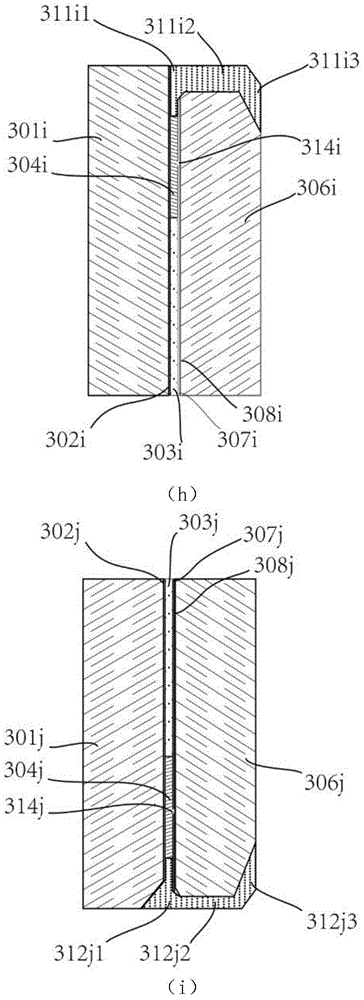

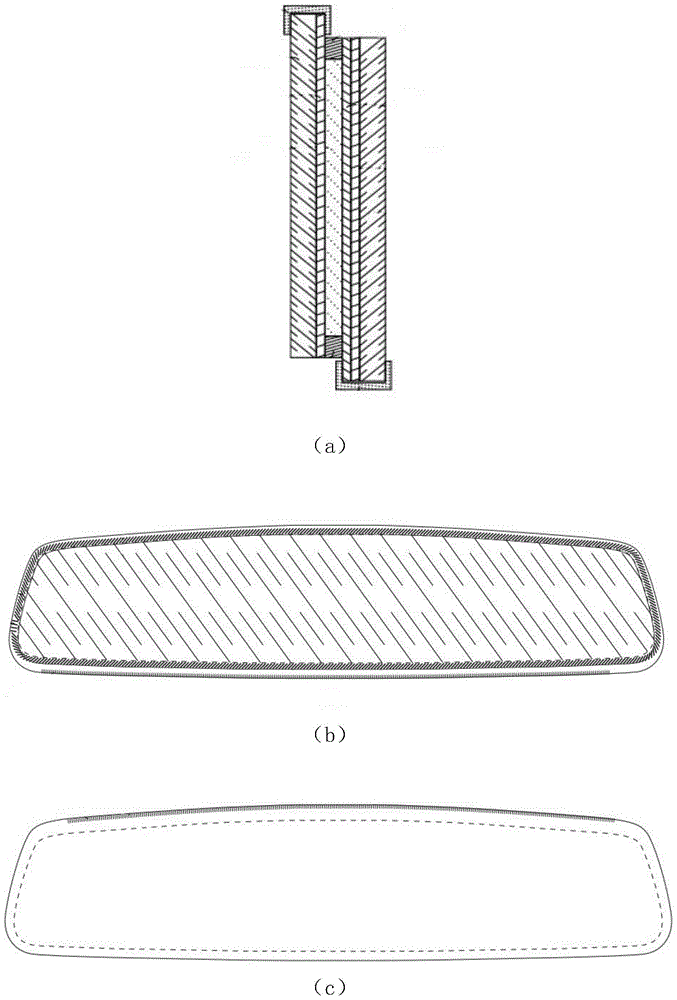

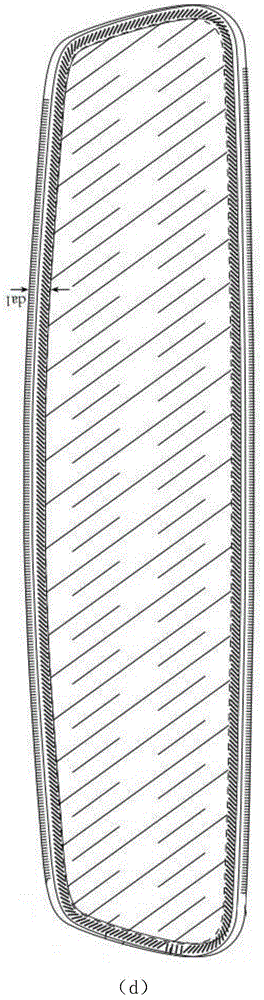

[0035] See image 3 , a packaging method for the manufacture of an electrochromic anti-glare device for a vehicle, comprising an anti-glare mirror; the anti-glare mirror has two upper and lower glass substrates; the specific steps are as follows:

[0036] ①Edge and chamfer one side of the conductive layer of the upper and lower glass substrates;

[0037] ② A dividing line is formed on the conductive layers of the upper and lower glass substrates by laser or chemical etching or diamond tools, so that the conductive layer is divided into two non-conductive conductive areas;

[0038] ③Apply the sealant around one of the glass substrates with a conductive layer, and leave a small section without glue coating as the injection port for pouring the electrochromic material;

[0039] ④ Put the conductive layer of another uncoated glass substrate facing down, and attach it to the glass substrate coated with sealant and the conductive layer facing up in step ③ to form a box structure wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com