Sludge and construction waste soil sintering and mixing method

A technology for construction waste soil and sludge, applied in chemical instruments and methods, clay products, applications, etc., can solve the problems of non-degradation, environmental pollution, and no handling of hand ends, etc., to ensure smoothness, reduce adhesion, and hardness. with high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

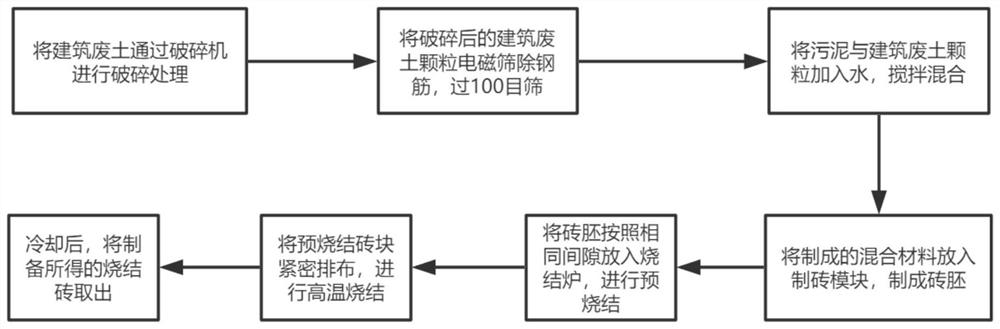

[0023] refer to figure 1 , a preferred embodiment of the present invention provides a method for sintering and mixing sludge and construction waste soil, comprising the following method steps:

[0024] S1. The construction waste soil is crushed by a jaw crusher to make construction waste soil particles, which are repeatedly crushed 3 to 4 times;

[0025] S2. Transport the crushed construction waste soil particles into the screening device, and electromagnetically screen the steel bars inside the construction waste soil particles. After screening for 3 times, pass the remaining construction waste soil particles through a 100-mesh sieve;

[0026] S3, transport the sludge and construction waste soil particles into the anchor mixer, add water, mix and stir, and the average stirring speed is 1200rpm;

[0027] S4. After stirring for 2 to 3 hours, put the mixed material made in S3 into the brick making module manually to make brick embryos;

[0028] S5. The brick embryos are manual...

Embodiment 2

[0037] A preferred embodiment of the present invention provides a method for sintering and mixing sludge and construction waste soil, comprising the following method steps:

[0038] S1. The construction waste soil is crushed by a jaw crusher to make construction waste soil particles, which are repeatedly crushed 3 to 4 times;

[0039] S2. Transport the crushed construction waste soil particles into the screening device, and electromagnetically screen the steel bars inside the construction waste soil particles. After screening for 3 times, pass the remaining construction waste soil particles through a 100-mesh sieve;

[0040] S3, transport the sludge and construction waste soil particles into the anchor mixer, add water, mix and stir, and the average stirring speed is 1500rpm;

[0041] S4. After stirring for 2 to 3 hours, put the mixed material made in S3 into the brick making module manually to make brick embryos;

[0042] S5, put the brick embryo into the inside of the sinte...

Embodiment 3

[0046] A preferred embodiment of the present invention provides a method for sintering and mixing sludge and construction waste soil, comprising the following method steps:

[0047] S1. The construction waste soil is crushed by a jaw crusher to make construction waste soil particles, which are repeatedly crushed 3 to 4 times;

[0048] S2. Transport the crushed construction waste soil particles into the screening device, and electromagnetically screen the steel bars inside the construction waste soil particles. After screening for 3 times, pass the remaining construction waste soil particles through a 100-mesh sieve;

[0049] S3, transport the sludge and construction waste soil particles into the anchor mixer, add water, mix and stir, and the average stirring speed is 1200rpm;

[0050] S4. After stirring for 2 to 3 hours, put the mixed material made in S3 into the brick making module manually to make brick embryos;

[0051] S5. The brick embryos are manually measured for the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com