Dual-redundancy 270V high-voltage high-power load monitoring device

A high-power load and load monitoring technology, applied in the direction of output power conversion device, circuit layout on the support structure, cooling/ventilation/heating transformation, etc., can solve the problems of insufficient driving technology and poor heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

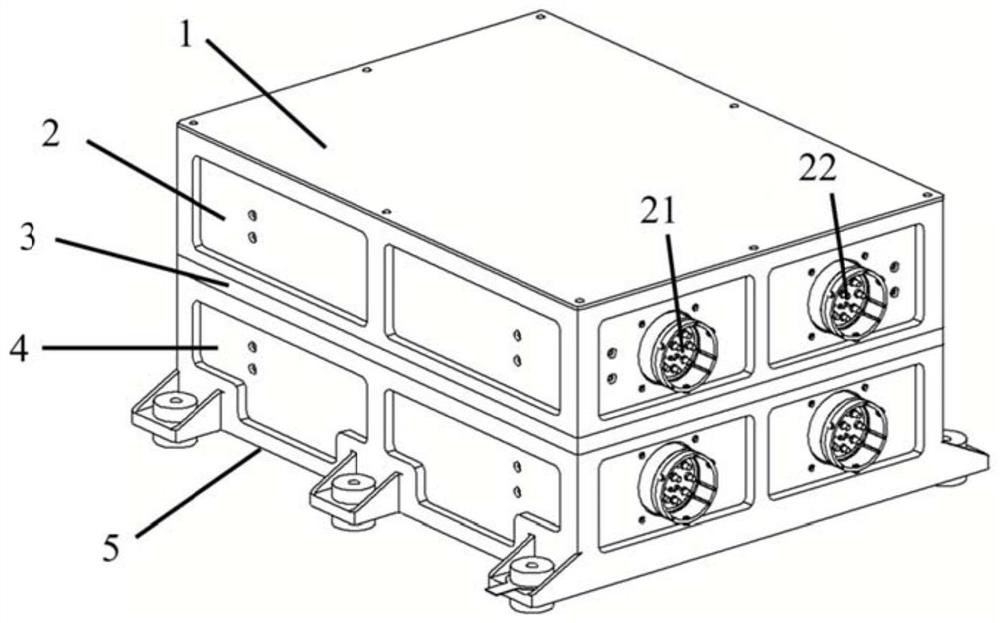

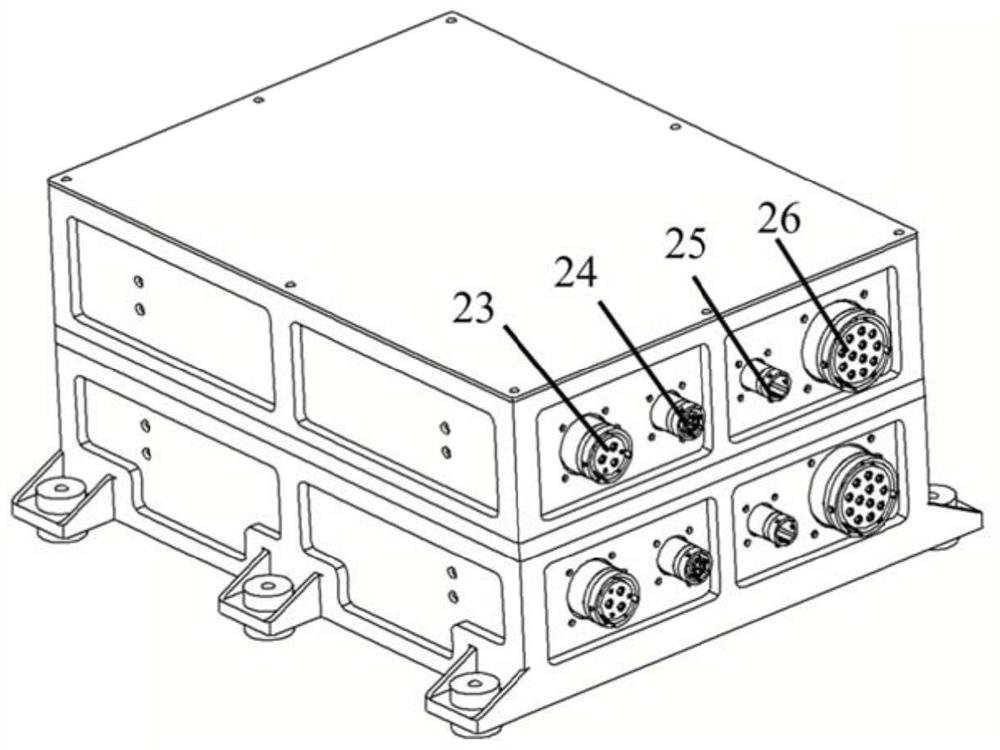

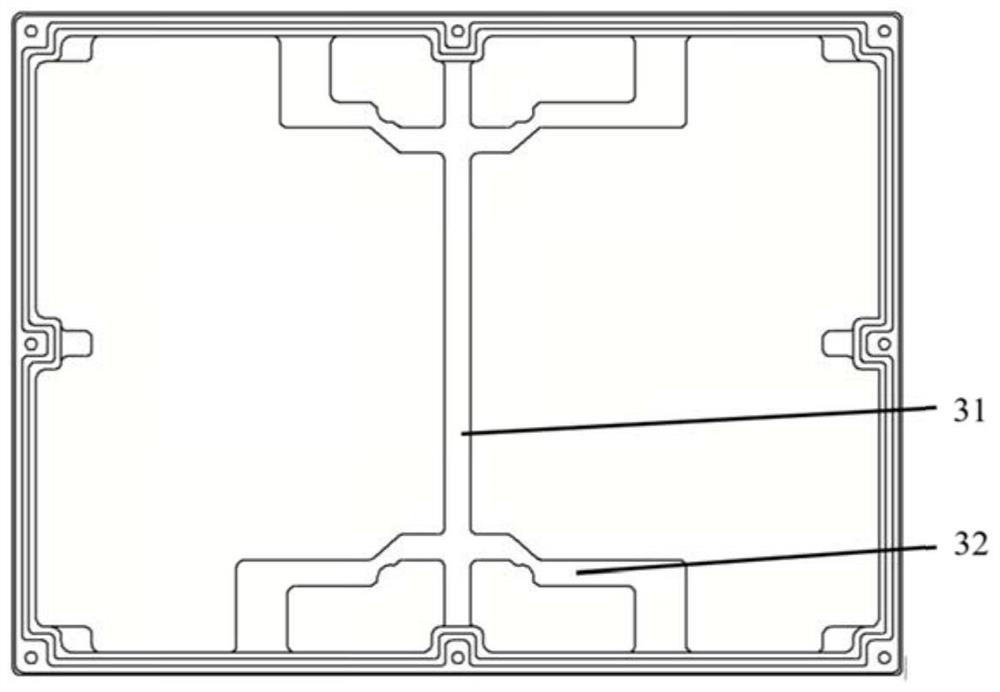

[0036] The double redundancy 270V high-voltage high-power load monitoring device of the present invention includes an upper shell 1, a first load monitoring unit 2, a partition 3, a second load monitoring unit 4 and a lower shell 5, the upper shell 1 and the partition The first load monitoring unit 2 is installed in the upper structure formed by the plate 3, the second load monitoring unit 4 is installed in the lower structure formed by the lower shell 5 and the partition plate 3, and the heat dissipation unit is installed in the upper shell 1 and the lower shell 5. The plate, together with the separator 3, promotes heat dissipation.

[0037] Both the first load monitoring unit 2 and the second load monitoring unit 4 include a high-power drive circuit installed on a printed board, and the drive circuit includes an isolated power supply, a boost device, a driver chip and a power MOSFET, and the driver chip and the power MOSFET A resistor R1, a resistor R2 and a resistor R3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com