Variable-range capacitive flexible pressure sensor and production method thereof

A pressure sensor and capacitive technology, applied in the field of flexible sensors and intelligent fluids, can solve the problems of high sensitivity and wide linear range that are difficult to achieve at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

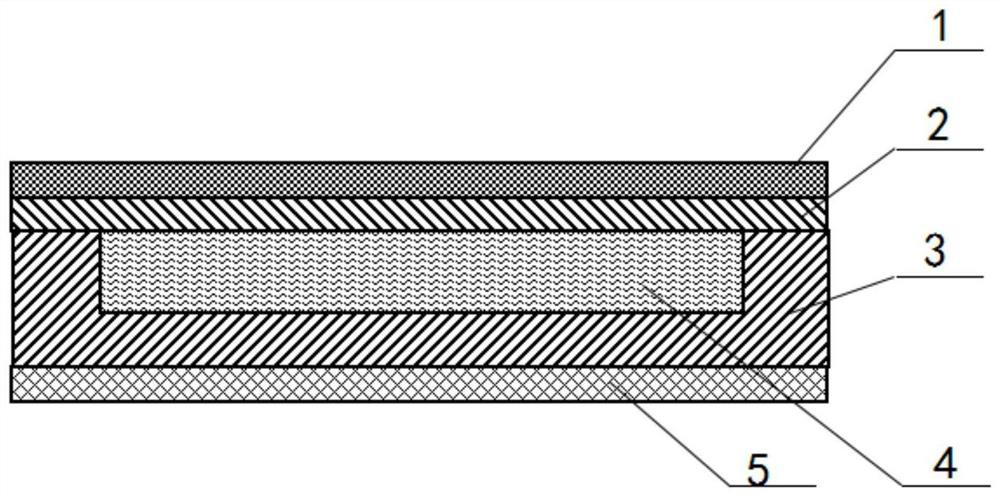

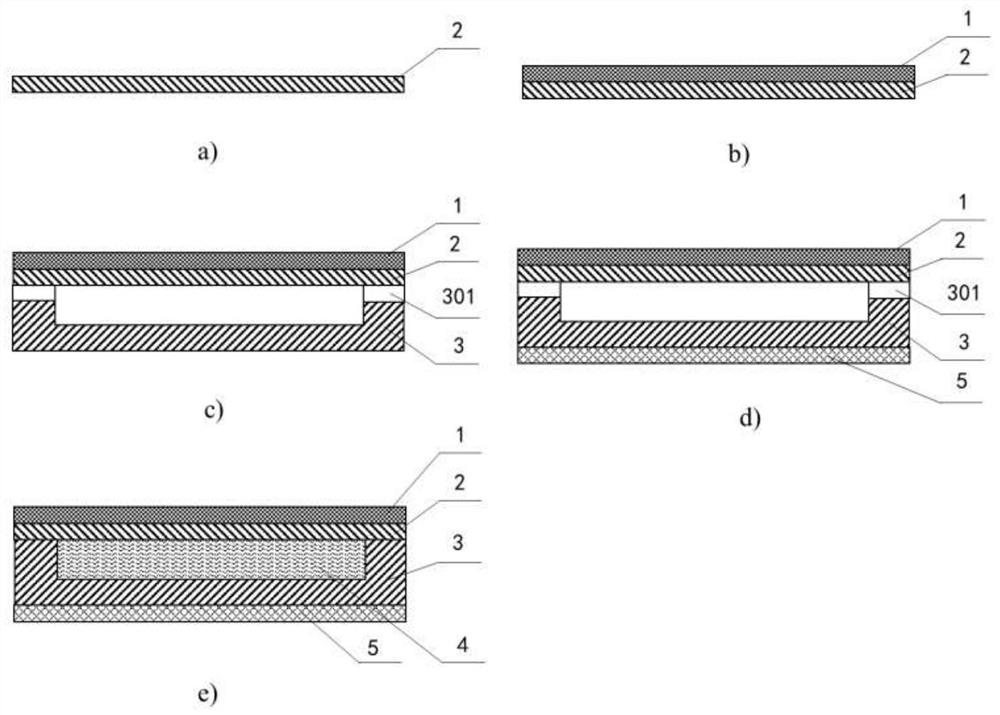

[0029] The variable-range capacitive flexible pressure sensor provided by the present invention (the structural schematic diagram sees figure 1 ), which includes an upper electrode layer 1, a flexible thin film layer 2, a flexible cavity 3 and a lower electrode layer 5 arranged in sequence from top to bottom, wherein the flexible cavity 3 is filled with an electrorheological medium 4; its preparation method includes the following steps (see flow chart figure 2 ):

[0030] 1) The flexible film layer 2 is prepared by a printing process;

[0031] 2) preparing an electrode layer 1 on the flexible film layer by using a deposition process;

[0032] 3) Prepare the flexible cavity 3 with through holes 301 at both ends by using the 3D printing method or the template method, and paste the flexible cavity 3 under the flexible film layer 2;

[0033] 4) Prepare a layer of electrode layer 5 under the flexible cavity 3 by using a deposition process;

[0034] 5) Inject the electrorheolog...

Embodiment 1

[0038] A variable-range capacitive flexible pressure sensor, the preparation method of which comprises the steps of:

[0039] 1) Evenly coat polydimethylsiloxane on a flat substrate, and cure at 60°C for 30 minutes to form a polydimethylsiloxane flexible film layer with a thickness of 200um (which can withstand 200% strain) ,Such as figure 2 a) as shown;

[0040] 2) Deposit a layer of copper film (thickness is 0.02mm) on the polydimethylsiloxane flexible film layer by sputtering process, as the upper electrode layer, such as figure 2 b) shown;

[0041] 3) Use Solidworks software to design the flexible cavity model, import the designed model into the photo-curing printer, and print the flexible compound (flexible photo-curing resin elastic) into a flexible cavity structure according to the designed model printer, clean and dry it with ultraviolet rays The flexible cavity was further cured for 20 minutes; after coating a layer of polydimethylsiloxane solution on the surface...

Embodiment 2

[0045] A variable-range capacitive flexible pressure sensor, the preparation method of which comprises the steps of:

[0046] 1) Evenly coat polydimethylsiloxane on a flat substrate, and cure at 60°C for 30 minutes to form a polydimethylsiloxane flexible film layer with a thickness of 200um;

[0047] 2) Deposit a copper film (0.02 mm in thickness) on the polydimethylsiloxane flexible film layer by sputtering process as the upper electrode layer;

[0048] 3) Use Solidworks software to design the mold model of the flexible cavity, import the designed model into the light-curing printer, and print the plastic compound (plastic light-curing resin clear) into the mold structure of the flexible cavity according to the designed model printer, after cleaning and drying Use ultraviolet light to further cure the mold for 20 minutes; inject polydimethylsiloxane into the mold after curing and heat-cure at 60°C for 30 minutes and then peel off to obtain a flexible cavity; polydimethylsilox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap