Comprehensive silica gel release film application

A release film, silicone technology, applied in the direction of adhesives, adhesive additives, film/sheet release liners, etc., can solve the problems of reverse peeling, affecting the performance, and low residual adhesion rate of the release film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

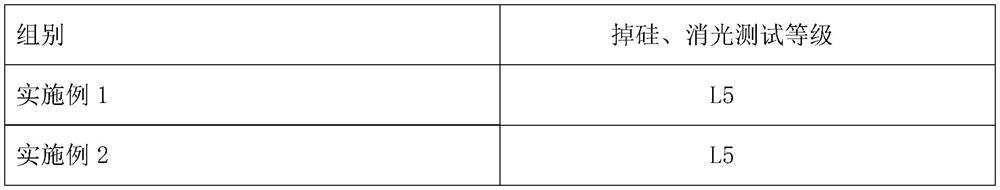

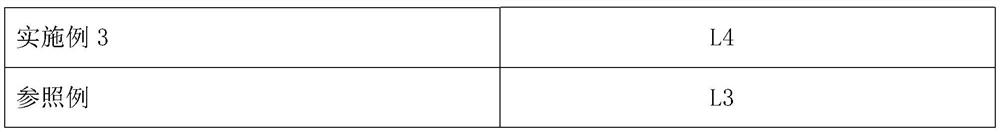

Examples

Embodiment 2

[0026] Completely prepared according to the method of Example 1, the difference from Example 1 is: the coating amount of the silica gel adhesive layer is 7g / m3, and the silica gel adhesive layer includes the following raw materials in parts by mass: 55-58 parts of organic silica gel adhesive , 2-3 parts of coupling agent, 2-4 parts of antistatic agent, 8-10 parts of anchoring agent, 3-5 parts of catalyst, 4-6 parts of polycarbonate.

Embodiment 3

[0028] Completely prepared according to the method of Example 1, the difference between Example 1 and Example 2 is: the coating amount of the silica gel adhesive layer is 3g / m3, and the silica gel adhesive layer includes the following raw materials in parts by mass: organic silica gel adhesive 50-55 parts, 1-3 parts of coupling agent, 2-3 parts of antistatic agent, 7-10 parts of anchoring agent, 3-4 parts of catalyst, 3-5 parts of polycarbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com