High-temperature-resistant silica gel sleeve and preparation method thereof

A technology of high temperature resistance and silicone, which is applied in the field of high temperature resistant silicone sleeve and its preparation, and can solve the problems affecting the normal performance of silicone tube, elastic fatigue, and inability to withstand high temperature for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

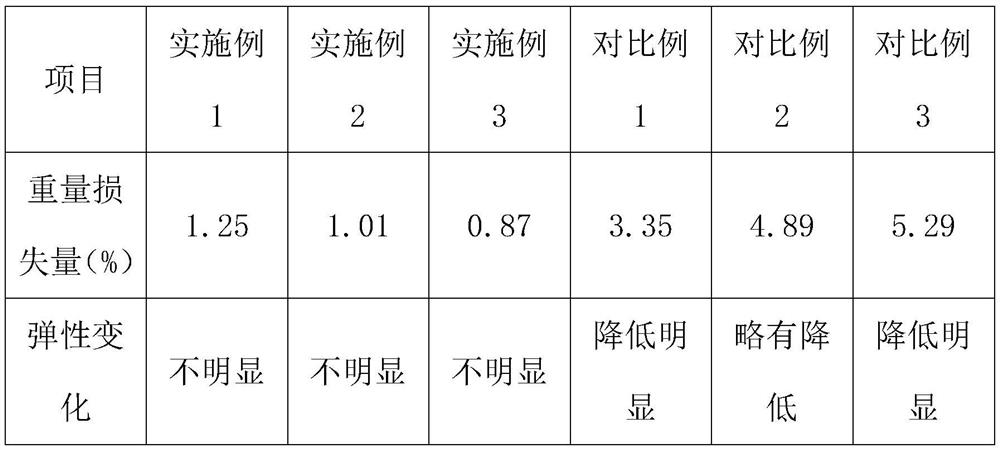

Examples

Embodiment 1

[0025] In Example 1, a high-temperature-resistant silicone sleeve adopts the following raw materials in proportion by mass: 100 parts of silicone rubber, 10 parts of thermoplastic resin, 1.5 parts of vulcanizing agent, 8 parts of phenyl silicone oil, 6 parts of titanium oxide, plasticized 3 parts of anti-aging agent, 1 part of anti-aging agent, 10 parts of propylene oxide glycerol polyether, 32 parts of high alumina clinker, 0.5 parts of aluminate coupling agent, 2 parts of silane coupling agent, 15 parts of magnesium stearate and polyformaldehyde 12 parts of triethoxysilane.

[0026] Further, the antiaging agent is a mixture of one or more of antiaging agent RD, antiaging agent 4010 or antiaging agent MB.

[0027] Further, the plasticizer is an alkylsulfonic acid phenyl ester compound.

[0028] Further, the silane coupling agent is one of silane coupling agent KH-550, silane coupling agent KH-558 or silane coupling agent KH-560, and the aluminate coupling agent is aluminate ...

Embodiment 2

[0033] In Example 2, a high-temperature-resistant silicone sleeve adopts the following raw materials in proportion by mass: 120 parts of silicone rubber, 15 parts of thermoplastic resin, 6 parts of vulcanizing agent, 16 parts of phenyl silicone oil, 12 parts of titanium oxide, plasticized 8 parts of anti-aging agent, 5 parts of anti-aging agent, 25 parts of propylene oxide glycerol polyether, 42 parts of high alumina clinker, 2 parts of aluminate coupling agent, 5 parts of silane coupling agent, 22 parts of magnesium stearate and polyformaldehyde 22 parts of triethoxysilane.

[0034] Further, the antiaging agent is a mixture of one or more of antiaging agent RD, antiaging agent 4010 or antiaging agent MB.

[0035] Further, the plasticizer is an alkylsulfonic acid phenyl ester compound.

[0036] Further, the silane coupling agent is one of silane coupling agent KH-550, silane coupling agent KH-558 or silane coupling agent KH-560, and the aluminate coupling agent is aluminate c...

Embodiment 3

[0041] In Example 3, a high-temperature-resistant silicone sleeve adopts the following raw materials in proportion by mass: 110 parts of silicone rubber, 12 parts of thermoplastic resin, 8 parts of reinforcing agent, 4 parts of vulcanizing agent, 12 parts of phenyl silicone oil, oxidized 9 parts of titanium, 6 parts of plasticizer, 4 parts of anti-aging agent, 18 parts of propylene oxide glycerol polyether, 36 parts of high alumina clinker, 1 part of aluminate coupling agent, 3 parts of silane coupling agent, stearic acid 18 parts magnesium and 18 parts polymethyltriethoxysilane.

[0042] Further, the antiaging agent is a mixture of one or more of antiaging agent RD, antiaging agent 4010 or antiaging agent MB.

[0043] Further, the plasticizer is an alkylsulfonic acid phenyl ester compound.

[0044] Further, the silane coupling agent is one of silane coupling agent KH-550, silane coupling agent KH-558 or silane coupling agent KH-560, and the aluminate coupling agent is alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com