Environment-friendly low-precipitation soft PVC material and preparation method thereof

A PVC material and soft technology, which is applied in the field of environmental protection and low precipitation soft PVC material and preparation, can solve the problems that the precipitation rate cannot meet the requirements, reduce the precipitation rate, and cannot meet the medical requirements, etc.

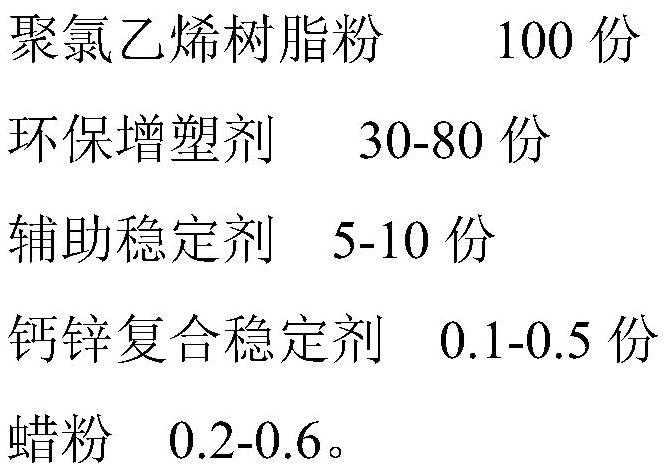

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A kind of preparation of environment-friendly low precipitation soft PVC material comprises the following steps:

[0031] (1) Preparation of auxiliary stabilizer: add linseed oil and soybean oil to formic acid, stir and mix at 25°C, the stirring speed is 9000r / min, slowly add hydrogen peroxide containing catalyst, control the reaction temperature and keep it at 60°C, and the stirring speed is The epoxidation reaction was carried out at 1300r / min. After the hydrogen peroxide was added, and the temperature was kept at 60°C, the reaction was continued for 11 hours. The mass ratio of the linseed oil, soybean oil and formic acid is 60:40:20. The mass ratio of the catalyst to the hydrogen peroxide is 1:30; the mass ratio of the hydrogen peroxide to the linseed oil is 2:1. The catalyst is phosphoric acid.

[0032] (2) Preparation of calcium-zinc composite stabilizer: calcium stearate, zinc stearate, polyethylene wax, β-(3,5-ditert-tert Butyl-4-hydroxyphenyl) n-octadecyl pro...

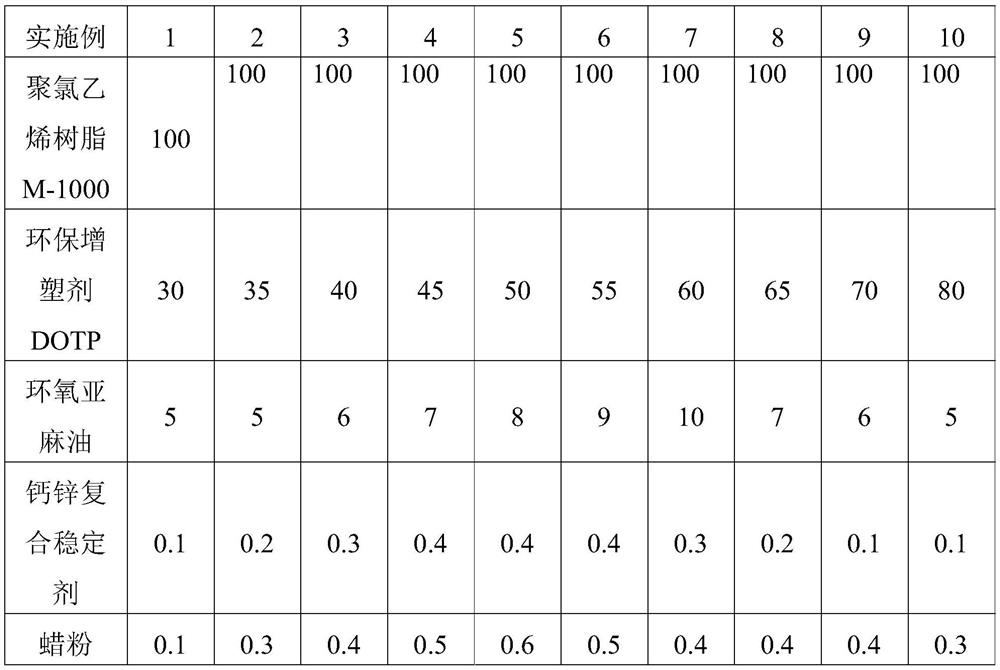

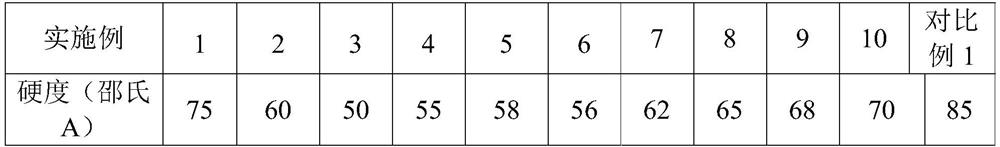

Embodiment 1-10

[0035] The parts by weight of the raw materials used in each embodiment are shown in Table 1 below:

[0036] Table 1, the amount of each component is in kg

[0037]

Embodiment 11

[0056] A kind of preparation of environment-friendly low precipitation soft PVC material comprises the following steps:

[0057] (1) Preparation of auxiliary stabilizer: Add linseed oil and soybean oil to formic acid, stir and mix at 20°C, the stirring speed is 800r / min, slowly add hydrogen peroxide containing catalyst, control the reaction temperature to remain at 50°C, and the stirring speed is The epoxidation reaction was carried out at 1200r / min. After the hydrogen peroxide was added, and the temperature was kept at 50°C, the reaction was continued for 10 hours. The mass ratio of the linseed oil, soybean oil and formic acid is 50:50:10. The mass ratio of the catalyst to the hydrogen peroxide is 1:20; the mass ratio of the hydrogen peroxide to the linseed oil is 1:1. The catalyst is titanium dioxide.

[0058] (2) Preparation of calcium-zinc composite stabilizer: calcium stearate, zinc stearate, polyethylene wax, β-(3,5-ditert-tert Butyl-4-hydroxyphenyl) n-octadecyl propi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com