Degradable film and preparation method thereof

A technology for degrading membranes and solvents, applied in the field of membrane materials, can solve problems such as mechanical properties that have not been reported yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

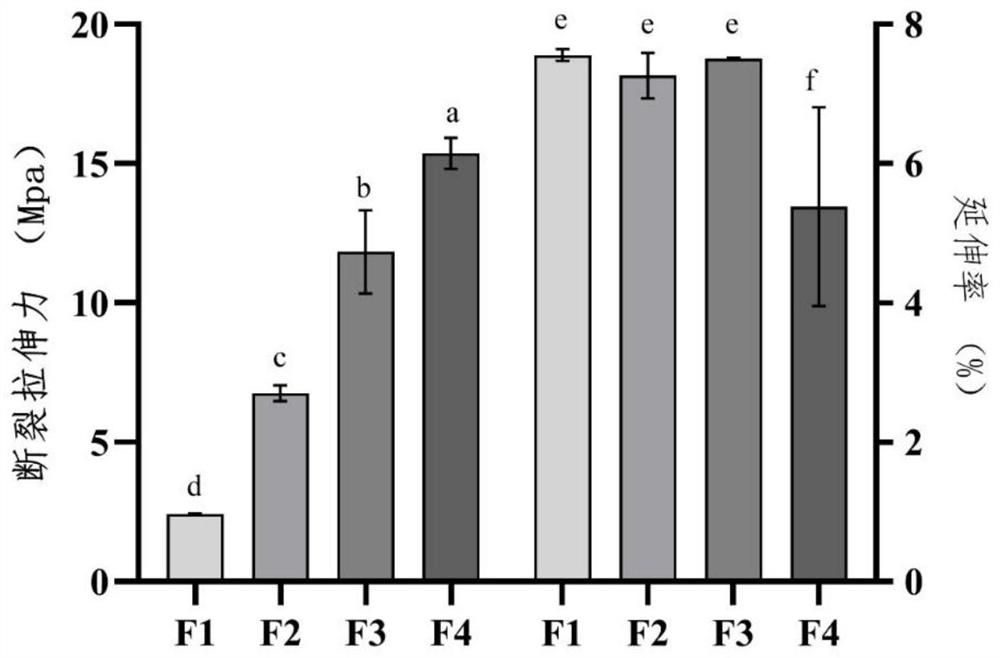

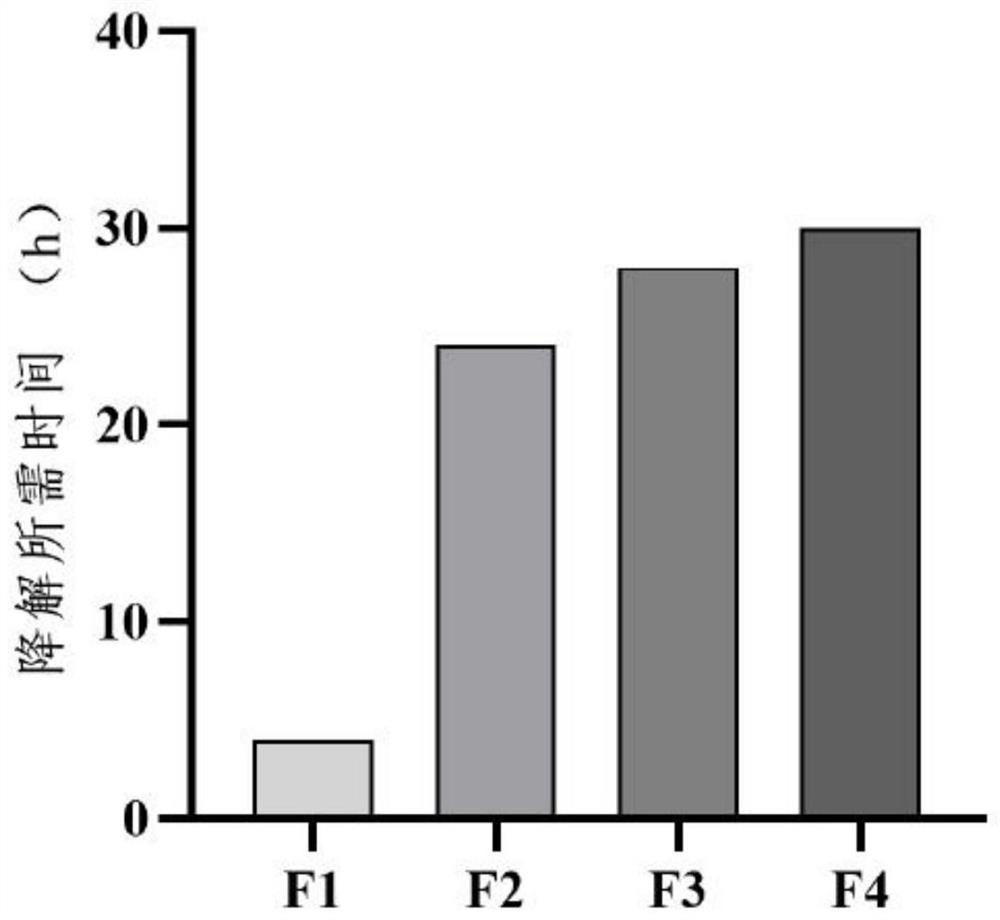

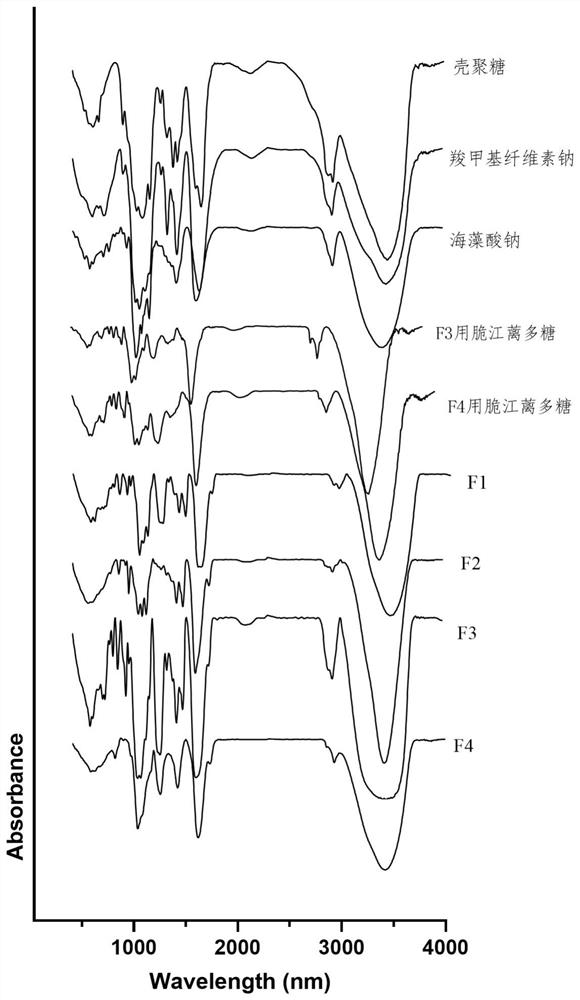

[0042] Choline chloride, glycerin, and lactic acid are heated and stirred at 60° C. in a mass ratio of 3:2:2 to a colorless and transparent solution, which is the DES solution required by the present invention. Weigh 1 part of Gracilaria brittle polysaccharide (molecular weight is 298.8kDa), dissolve it in 50 parts of water after adding 0.5 part of DES; add 1 part of DES solvent to chitosan (0.5 part) and sodium carboxymethyl cellulose (0.1 part) After dissolving in 50 parts of water, slowly pour the blend of chitosan and sodium carboxymethylcellulose into the Gracilaria brittle solution at 50° C., and stir the mixed solution to a uniform state. Pour the uniformly mixed solution into a petri dish with a diameter of 6 cm and a thickness of 8-10 mm, dry at 60°C, peel off the film and record it as F3.

Embodiment 2

[0044] Choline chloride, glycerin, and lactic acid are heated and stirred at 60°C until a colorless and transparent solution is obtained, which is the DES solution required by the present invention. Weigh 1 part of Gracilaria brittle polysaccharide (molecular weight is 501.4kDa), dissolve it in 50 parts of water after adding 0.5 part of DES; add 1 part of DES solvent to chitosan (0.5 part) and sodium carboxymethyl cellulose (0.1 part) After dissolving in 50 parts of water, slowly pour the blend of chitosan and sodium carboxymethyl cellulose into the Gracilaria brittle solution at 50° C., and stir until it is uniform. Pour the uniformly mixed solution into a petri dish with a diameter of 6 cm and a thickness of 8-10 mm, dry at 60°C, peel off the film and record it as F4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com